Powerhead installation, Cutter blade adjustment – Shindaiwa 63848-94010 User Manual

Page 11

AH231_09

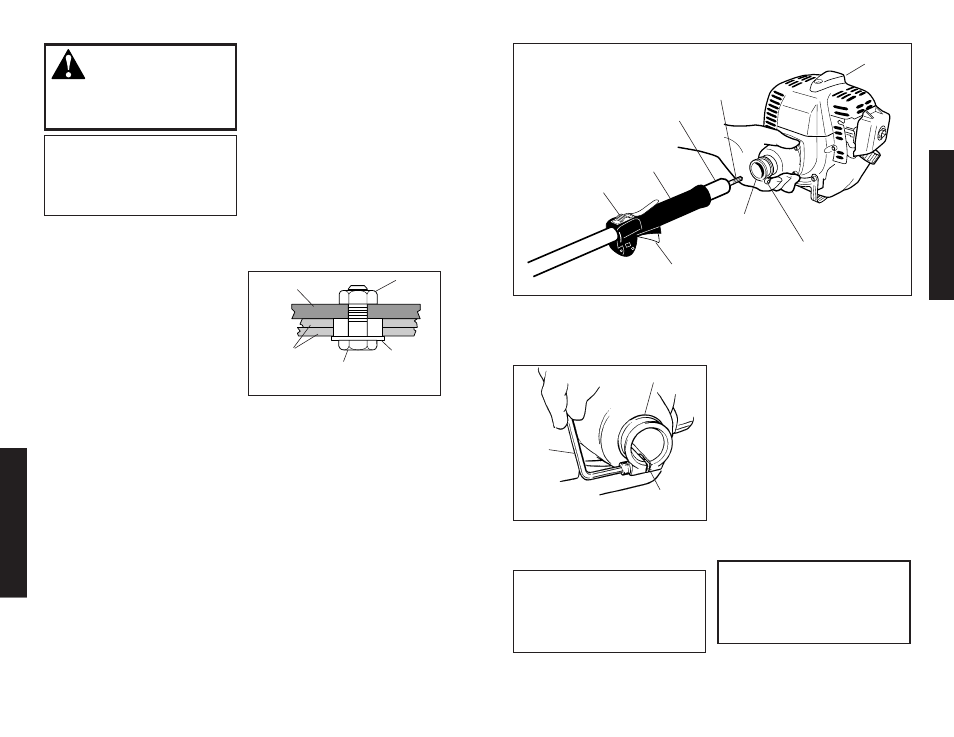

Powerhead Installation

1. Place the powerhead on a clean, flat

surface, spark plug facing up.

2. Use the 4mm hex wrench to loosen

Tube Clamp

Hex

Wrench

Shim Washer

Connect the Outer Tube to the Powerhead.

the tube clamp screw. Verify that

the D-shaped shim washer is

positioned as shown in Figure 6.

3. Add some moly-type EP grease to

splines at the end of the main shaft.

4. Slide the outer tube into the tube

clamp until the tube bottoms. If

installation is difficult, rotate the

outer tube or main shaft slightly

until you feel the mainshaft splines

engage with the powerhead.

See Figure 5.

5. Position the outer tube so that the

ignition switch is facing up and the

throttle lever is facing down.

See Figure 5.

6. Slide the outer tube into the

powerhead until the throttle grip

just contacts the tube clamp.

7. Tighten the clamp screw firmly.

Figure 6

10

Grip

Spark

Plug

Ignition

Switch

Main

Shaft

Tube

Clamp

Outer Tube

Clamp Screw

Figure 5

Throttle Lever

CAUTION!

Do not force the shaft tube into the

powerhead! Excessive force can

damage the shaft tube and

mainshaft.

CAUTION!

Do not remove the D-shaped shim

washer! The shim washer pre-

vents damage from overtightening

the tube clamp screw.

ASSEMBLY

Cutter performance of your unit

depends in great measure on cutter

blade clearance. Properly adjusted

blades will oscillate freely yet help

prevent binding of cut material

between blades. Adjust blades as

follows (Figure 32):

AH231_38

Guide Bar

Locknut

Cutter Blades

Shoulder

Bolt

Washer

(should turn

freely)

Figure 32

Cutter Blade Adjustment

1. Loosen all blade locknuts at least

one full turn.

2. Tighten each blade shoulder bolt

firmly, and then loosen the shoul-

der bolts 1/4 to 1/2 turn.

3. Working from the gearcase end,

lock each bolt in place by firmly

tightening its locknut while

preventing the shoulder bolt from

turning.

When shoulder bolt adjustment is

correct, there should be a gap of

0.25–0.50 mm between the cutter

blades and the flat washers, and the

flat washer beneath each bolt head

should turn freely.

CAUTION!

Operating the trimmer with worn or

improperly adjusted cutters will

reduce cutter performance and

may also damage your unit.

WARNING!

The cutter blades are very sharp!

Always wear gloves when working

around the cutter assembly.

25

MAINTENANCE