Technical specifications – Shindaiwa 68002-94310 User Manual

Page 9

9

Technical Specifications

Engine Type ........................... 2-Cycle,

vertical-cylinder, air-cooled

Displacement ....... 4.5 cu. in.

(73.5cc)*

Bore x Stroke .. 2 x 1.4 in. (51 x 36mm)

Max. Power Output** .. 4.

5 hp (3.3kW)

Recommended Engine Idling

Speed ................ 2,500 min

-1

(rpm)**

Recommended Maximum Engine

Speed ............. 10,550 min

-1

(rpm)**

Maximum Cutting Depth, EC7500

Abrasive Wheel

12 in. (305mm) ........... 4 in. (102mm)

Diamond Wheel

12.5 in. (320mm) .... 4.4 in. (109mm)

Maximum Cutting Depth, EC7600

Abrasive Wheel

13.9 in. (355mm) ........ 5 in. (127mm)

Diamond Wheel

14.1 in. (360mm) .... 5.1 in. (129mm)

Rated Spindle Speed†

EC7500 ............... 3,800 min

-1

(rpm)

EC7600 ................ 3,320 min

-1

(rpm)

Maximum Spindle Speed†

EC7500 ................ 4,220 min

-1

(rpm)

EC7600 ............... 3,680 min

-1

(rpm)

Maximum Peripheral Wheel Speed†

EC7500 .... 13,300 ft/min. (67.5m/sec)

EC7600 .... 13,500 ft/min. (68.0m/sec)

Speed Reduction Ratio

EC7500 .................................. 2.50:1

EC7600 .................................. 2.87:1

Type of Fuel ........... Unleaded gasoline

plus 2-cycle engine oil (50:1)

Fuel Tank Capacity ................... 800ml

Carburetor Type ................ Diaphragm

Ignition System ................... Electronic

Spark Plug ................ Champion, CJ6Y

Engine Starting/Stopping ..................

Toggle switch, recoil starter

Power Transmission .......... Automatic

centrifugal clutch, V-ribbed belt

Anti-Vibration System ............. Unified

handles with 7-point support

Safety Devices ......... Throttle lock-out,

wheel guard

Dry Weight (without wheel)

EC7500 .................... 22 lbs (10.0kg)

EC7600 .................... 23 lbs (10.5kg)

Dimensions (L x W x H)

EC7500 ............ 29.1 x 8.6 x 14.7 in.

(740 x 220 x 375mm)

EC7600 ............ 30.1 x 8.6 x 15.3 in.

(765 x 220 x 390mm)

Sound Pressure Level†

EC7500 ........................... 101 dB (A)

EC7600 ........................... 101 dB (A)

Sound Power Level††

EC7500 ........................... 108 dB (A)

EC7600 ........................... 111 dB (A)

Vibration Level§

Front handle (idle/rated spindle)

EC7500 .................. 6.96/5.48m/sec

2

EC7600 .............. 10.09/10.49m/sec

2

Rear handle (idle/rated spindle)

EC7500 ................ 8.61/14.60m/sec

2

EC7600 ................ 8.93/13.70m/sec

2

Recommended Cut-off Wheels

EC7500, abrasive ..... 12 in. (305mm) dia

EC7500, diamond .. 12.5 in. (320mm) dia

EC7600, abrasive .. 13.9 in. (355mm) dia

EC7600, diamond .. 14.2 in. (360mm) dia

Arbor Sizes ..................... 0.78" (20mm),

0.86" (22mm), and 1.0" (25.4mm)

*

Measured in accordance with EN ISO 11201:

1995.

** Measured in accordance with ISO 7293: 1983.

†

Measured with 305mm wheel (EC7500) and

355mm wheel (EC7600).

†† Measured in accordance with EN ISO 3744:

1995.

§

Measured in accordance with EN 28662-1:

1992.

20

EC7500.47

EC7500.36

EC7500.35

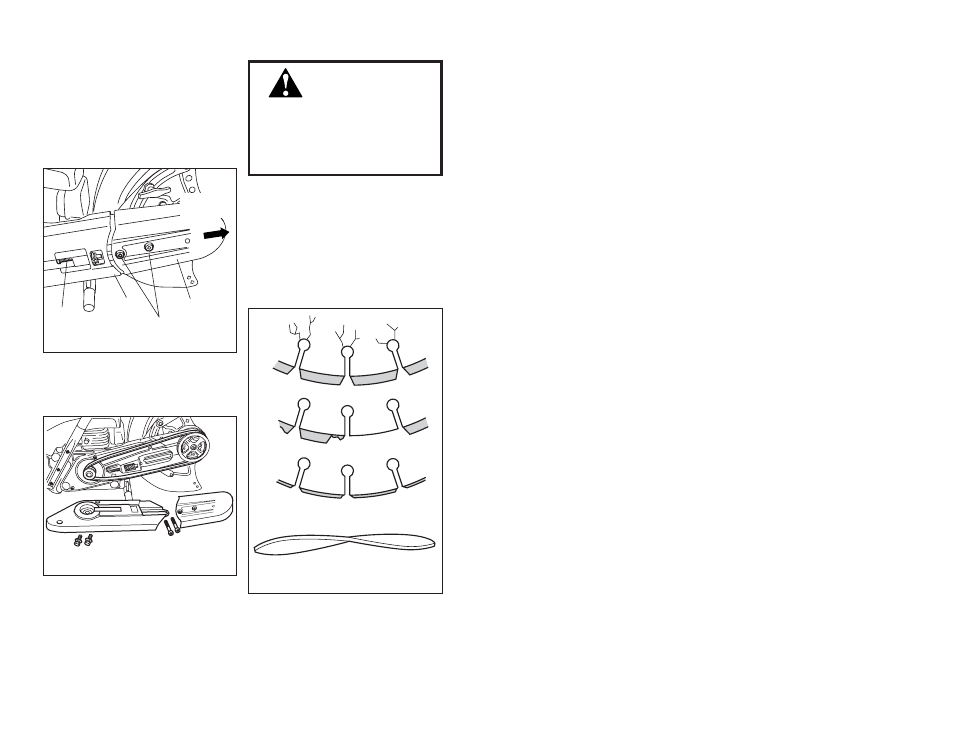

Replacing the Drive Belt

1. Loosen the tension screw. Loosen

the two bolts on the belt guard and

remove the belt guard by sliding it

to the right. See Figure 26.

2. Loosen the two bolts in the clutch

cover and remove the clutch cover.

3. Replace the old belt with a new one.

Figure 26

Tension

Screw

Clutch

Cover

Bolt

Belt Guard

4. Reassemble the clutch cover and

the belt guard and adjust the belt

tension. Figure 27 illustrates the

components.

Slide

forward to

remove

Figure 27

WARNING!

Never use a wheel which has

breakage, cracks or distortion.

The wheel may break while

operating and may result in

serious injury.

Always check the condition of the cut-

off wheel before starting the engine.

Make sure there are no breaks, cracks

or warps. See Figure 28.

A faulty wheel must be replaced

with a new one!

The tips of a diamond wheel should be

sharpened regularly to maintain

cutting efficiency. See page 22.

Figure 28

Cracks

Missing

Tips

Worn Tips

Distortion or Warps

Checking the Cut-off Wheel