Single fire operation, Clearing jammed staples – Woodstock SHOP FOX W1778 User Manual

Page 11

Model W1778 18 Gauge Deep Stapler Kit

-9-

5. Pull the trigger.

— If the staple drove into the wood

far enough, continue with your

intended operations.

— If the staple either went too far

or not far enough, then adjust the

air pressure. More air pressure

will increase staple depth, less

air pressure will decrease staple

depth.

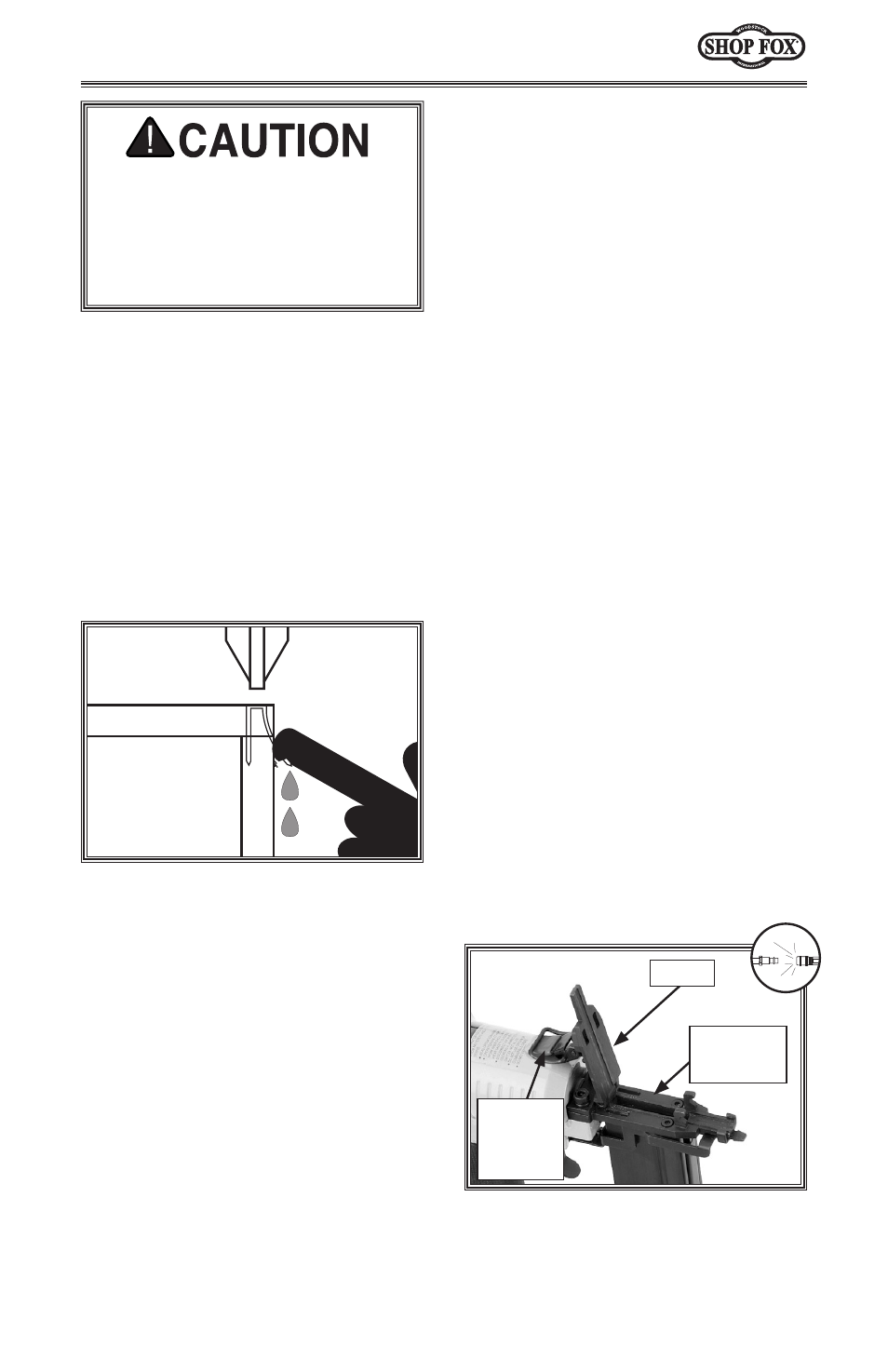

Deflection is caused when grain

irregularities, knots or foreign objects

inside the wood cause the staple

to change its path, resulting in the

staple puncturing the surface of the

workpiece, as shown in

Figure 5.

Besides damaging your workpiece,

deflection can cause injury if your

free hand is securing the workpiece in

the location that the staple deflects.

Figure 5. Example of staple deflection.

The stapler is designed to fire one staple

at a time.

To operate your stapler in single fire

mode, do these steps:

1. Depress the safety nose mechanism

against the workpiece.

2. Pull the trigger, then release the

trigger after the staple is driven.

Single Fire Operation

A jammed staple must be cleared before

using the stapler again.

To clear a jammed staple from the dis-

charge area, do these steps:

1. DISCONNECT STAPLER FROM THE AIR

SUPPLY!

2. Unlock the catch lever and slide the

magazine pusher all the way back.

3. Remove the staple stick from the

magazine.

4. Flip the quick release latch, as shown

in

Figure 6, and open the cover.

Clearing Jammed

Staples

Figure 6. Nose opened to clear a jam.

Cover

Discharge

Area

Quick

Release

Latch

5. The jammed staple should now be

visible; remove it from the discharge

area with needle nose pliers.

DO NOT place your hands near the

staple point of entry. A staple can

deflect and tear through the surface

of the workpiece, puncturing your

hand or fingers.