Shindaiwa HomePro 41RS Broadcast User Manual

Page 5

HOW TO DETERMINE SPREADER

SETTINGS AND SPREAD WIDTH

EFFECTIVE PATTERN WIDTH

APPLICATION RATE

Two major factors should be considered when determining correct spreader settings of

any product:

The product application rate, or the amount of material applied per 1,000 square feet.

1.

The effective pattern width, or the actual width in which material is applied. Label set-

2.

tings are a guide and can be affected by numerous factors.

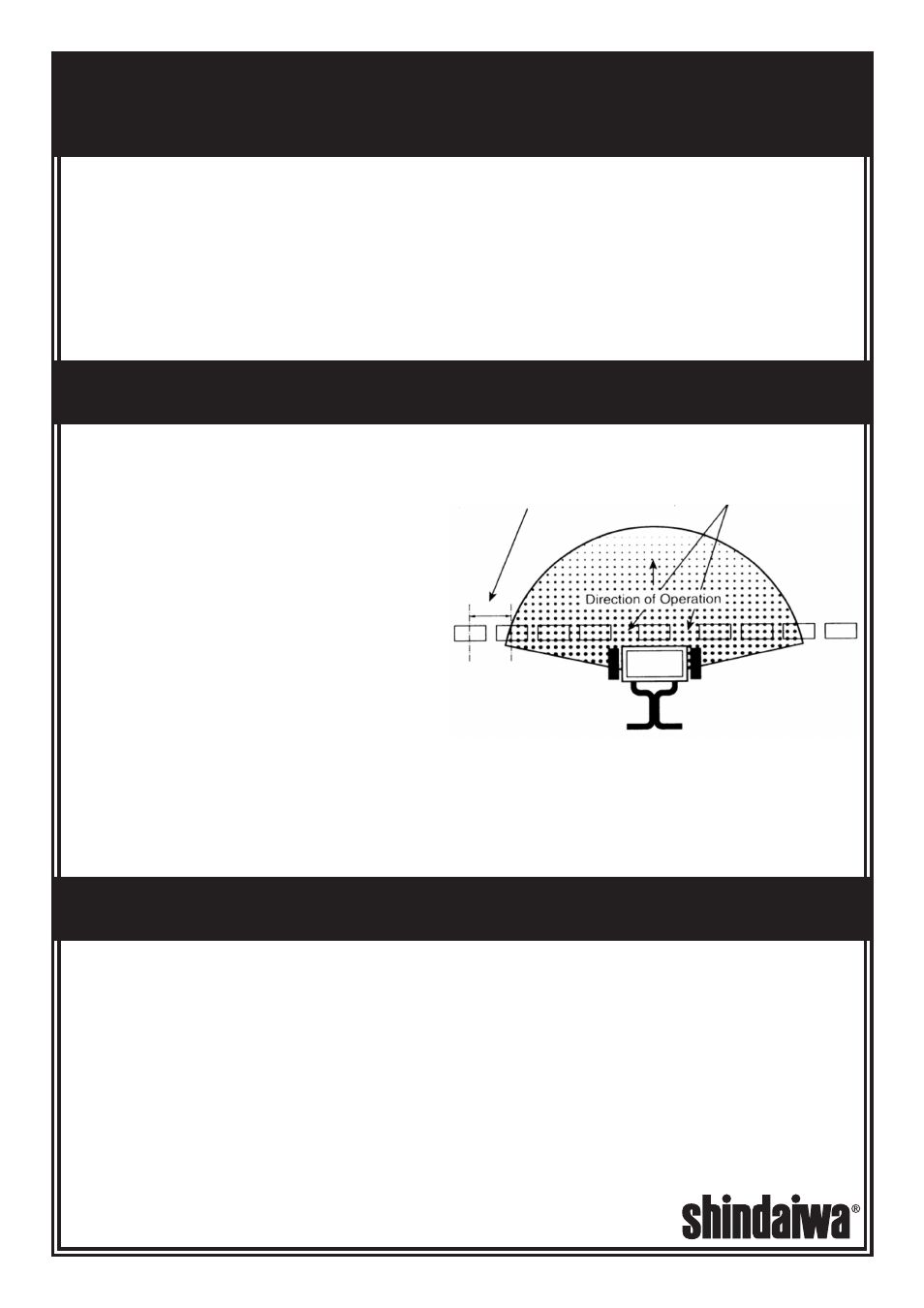

A simple visual pattern test can be made

by operating the spreader over a non-

turf area and evaluating the pattern. A

more accurate method is to place a row

of common, disposable, aluminum cake

pans approximately 1 foot on centers.

Set the rate cam at a middle setting and

make 3 or 4 passes in the same direc-

tion as shown. Pour the material collected

from each pan into individual bottles of

the same size. Set them side by side in

order, and visually inspect their volume.

The effective pattern width is the distance

out from the spreader to a point where

the amount of material is 1/2 the average

amount in the center pans. This distance

is multiplied by 2 to achieve the total

effective pattern width.

Knowing the effective pattern width (for exam-

ple, 10 feet), measure a distance equal to 100

square feet (10’ x 10’ swath width). Determine

the product coverage is pounds/ 100 sq. ft. by

the recommended square foot coverage (add

two zeroes to the weight of the bag).

EXAMPLE: Product weight: 25 lbs. sq. ft.

coverage: 5,000 sq. ft. 2500 lbs. - 5,000

sq. ft. = .5 lbs. / 100 sq. ft.

Weigh out between 15 to 20 lbs. of material

and spread over the 100 sq. ft. area. Weigh

remaining material left in hopper and adjust

rate setting as required. Repeat test until

application rate is correct.

Space Pan 1’0” on Centers Space for Wheel Track