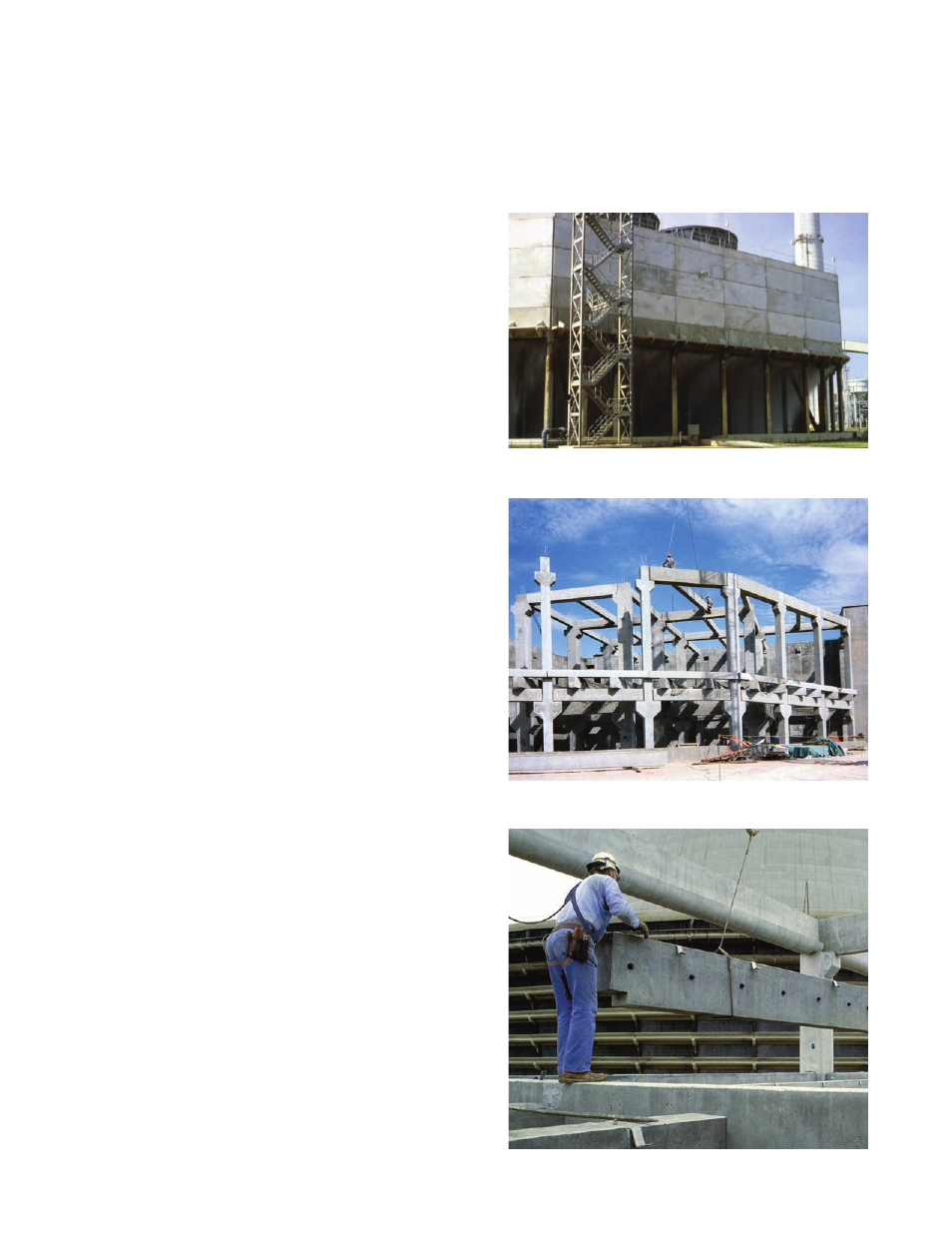

Concrete fits the marley “total systems” approach – SPX Cooling Technologies Mechanical Draft Cooling Tower Class 800 User Manual

Page 7

Class 800 technology produces a product with

definite, predictable and measurable performance.

Extensive laboratory, university and field testing for

long-term service in various climates and circulating

water conditions has enabled us to simulate and

evaluate tower longevity and performance.

Here are a few of the advantages of this structure:

•

Durability

Impervious to a broad range of corrosive

substances—immune to rot and decay.

• Fire resistant

Marley concrete counterflow cooling towers

with our standard hanging fill are Factory Mutual

approved. Sprinkler systems are not required,

saving on first cost and maintenance expense.

• Ease of construction

Local trades have many craftspeople with

bridge and building experience, and most cities

in the world have concrete mix and precast

plants. Concrete alone keeps the majority

of your cooling tower costs within the local

economy.

• Very stable

Coefficient of thermal expansion is less than

steel.

• Intermittent operation

Concrete is perfect for “cycled” cooling towers

as it naturally maintains its structural integrity,

whether wet or dry.

• Non-conductive

Reduces the hazard of electrical shock.

• Environmentally friendly

/ Concrete fits the Marley “Total Systems” approach /