Installation / maintenance 5, Maintenance, Cleaning the check valve – Simer Pumps Condensate Pump 2520ULST User Manual

Page 5: Testing auxiliary safety switch

Installation / Maintenance

5

For parts or assistance, call Simer Customer Service at

1-800-468-7867 / 1-800-546-7867

H.

Risk of Flooding. With installation

No. 2 (“Safety Switch Sounds Alarm”), the alarm is

activated when the water level in the reservoir is

within about 1/2" of the top of the reservoir.

However,

the furnace/AC unit will continue to pro-

duce condensate because the alarm will not shut it

down. Monitor the installation so that in case of

high water level in the condensate reservoir you

can take action before the reservoir overflows and

flooding occurs.

Testing Auxiliary Safety Switch:

NOTICE: Some appliances may not start immediately

due to a built-in delay circuit that prevents rapid cycling

of the compressor.

1. Start appliance.

2. Unplug the condensate pump so that it cannot

pump out.

3. Pour water into the pump reservoir until it is

almost full.

4. As the water rises in the reservoir, the safety switch

should shut down the appliance or set off the alarm

(depending on the installation procedure used).

5. Plug in the condensate pump and allow it to empty

the reservoir. As the water level goes down in the

reservoir, the safety switch should reset, allowing the

appliance to start or shutting off the alarm.

MAINTENANCE

1. Disconnect the power to the furnace/AC unit and

unplug the pump.

2. Disconnect the tubing to the pump. Drain the tubing

into a container.

3. Remove the two mounting screws and remove the

pump from the furnace or wall. Dump the reservoir

into a floor drain or container.

4. After you have dumped the pump, remove the four

screws securing the reservoir to the pump deck. Lift

the deck/pump assembly off of the reservoir.

5. Turn the deck/pump assembly upside down and

remove the five screws holding the impeller cover to

the motor.

6. Remove the impeller cover. The rotor/ impeller

assembly may come out with it. If not, pull it out of

the rotor chamber in the motor. (You may have to

pull it hard to get it out against the magnetism in the

motor windings.)

7. Clean the impeller, rotor, rotor cavity, and O-Ring.

Use a rag to clean the O-Ring groove in the impeller

cover and the sealing surface on the bottom of the

motor block.

8. Clean out the reservoir.

9. Reassemble the impeller and the impeller cover;

tighten the screws carefully. Do not overtighten!

10. Turn everything right side up and reassemble the

reservoir to the deck. Be sure the impeller cover fits

into the molded ring in the bottom of the reservoir.

Fasten the reservoir with the four screws at the

corners.

11. Reinstall the pump on the furnace.

12. Plug in the pump, fill the reservoir, and run the

pump through one complete pump-down cycle to

be sure it works correctly.

13. The pump is ready for operation.

CLEANING THE CHECK VALVE

1. Unplug the condensate pump.

2. Remove the discharge line from the check valve.

3. Use a 9/16" wrench to remove the check valve from

the pump deck.

4. Inspect the valve for obstructions or damage. Clean

or replace it as needed.

5. Thread the valve back into the pump discharge by

hand, plus 1/2 turn with the wrench.

NOTICE: Don’t overtighten the valve, as over-

tightening can distort the O-Ring that seals the valve,

causing leaks.

6. Plug in the pump, fill the reservoir, and run the

pump through one complete pump-down cycle to

be sure it works correctly.

7. The pump is ready for operation.

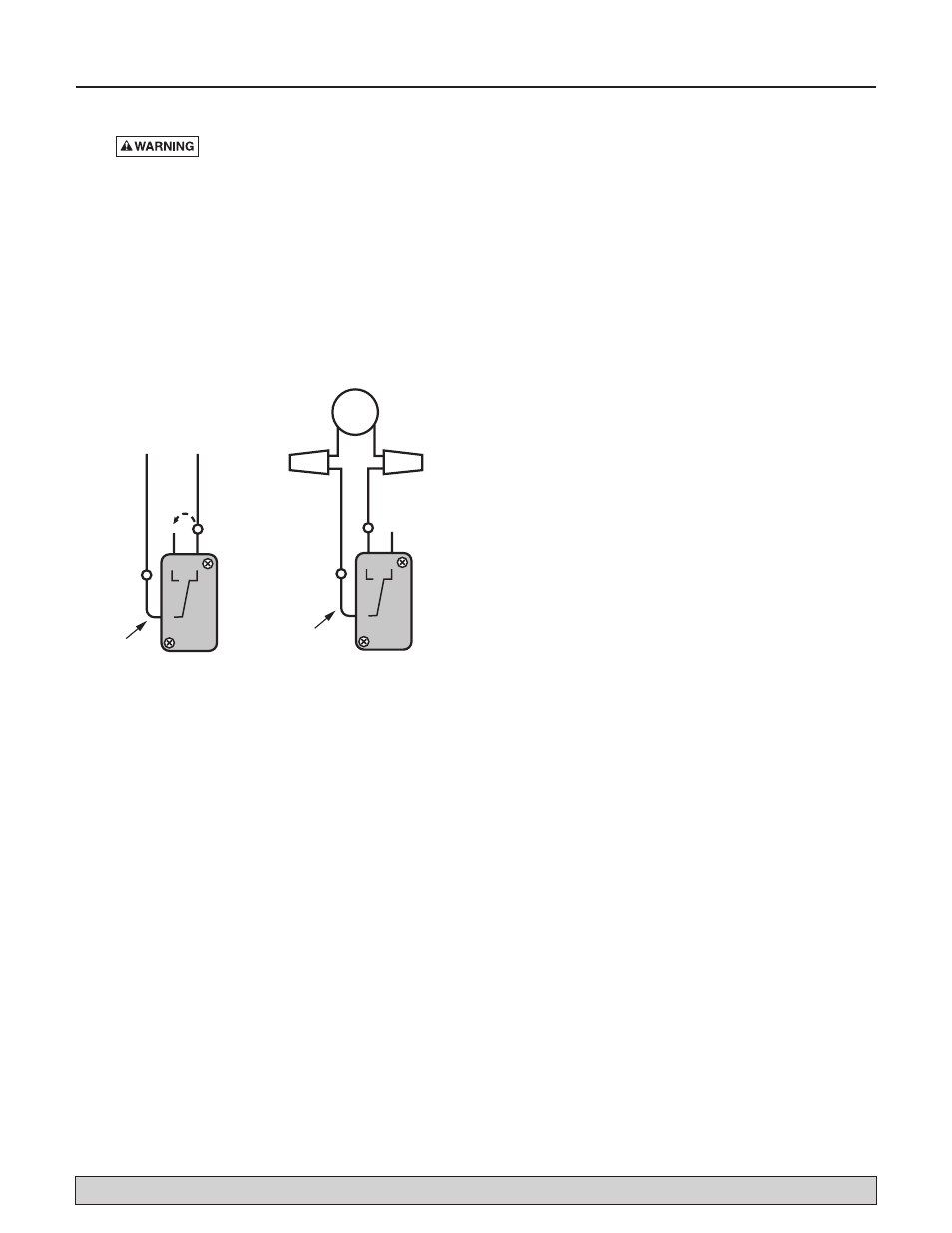

Safety Switch

Safety Switch

1. Move white lead

from NC terminal to

NO terminal

as shown.

Common

2. Connect both

white leads to

alarm with wire

nuts as shown

Alarm

White

White

C

NO

NC

1

2

3

Common

White

White

C

NO

NC

1

2

3

Figure 2: Low Voltage Auxiliary Safety Switch connec-

tion for alarm circuit installation (does not shut down

furnace/AC unit).