Troubleshooting, Trouble cause remedy – SPX Cooling Technologies CoolingTower Marley MCW User Manual

Page 27

27

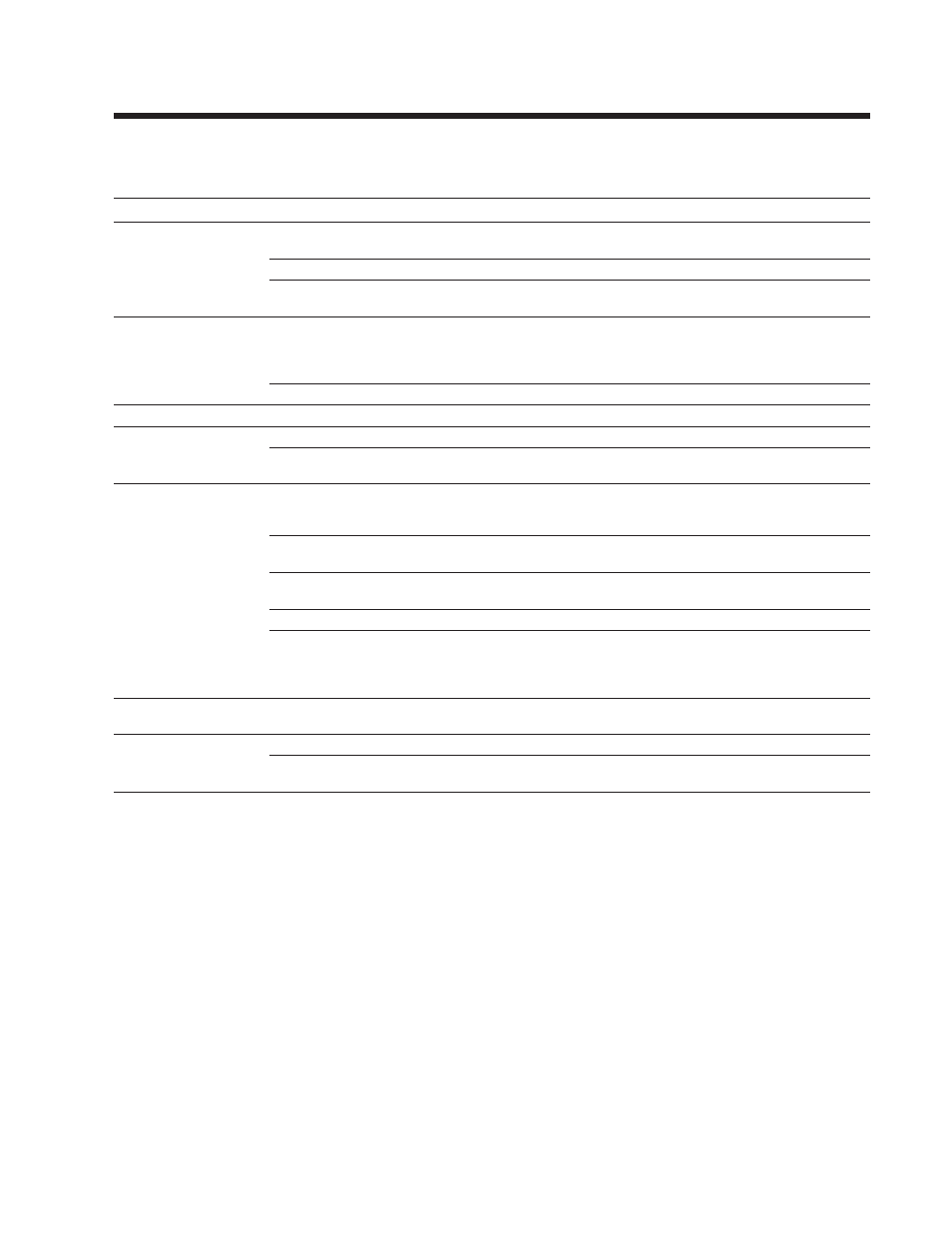

Troubleshooting

Trouble

Cause

remedy

Unusual fan drive vibration

Loose bolts and cap screws

Tighten all bolts and cap screws on all mechanical equipment and

supports.

Worn fan shaft bearings..

Check fan shaft endplay. Replace bearings as necessary.

Unbalanced motor

Disconnect load and operate motor. If motor still vibrates, rebalance

rotor.

Fan noise

Impeller rubbing inside of cylinder

Adjust fan impeller. Adjustment may need to be axial i.e. moving

impeller along the shaft to centralize it between the cylinders or radial

by repositioning bearing or bearings to get the impeller concentric

within the inlets.

Fan shaft bearing.

Grease bearings.

Belt squeal or chirping

Belt slipping

Adjust belt

Scale or foreign substance in

circulating water system

Insufficient blowdown

See "Water Treatment" section of this manual.

Water treatment deficiency

Consult competent water treating specialist. See "Water Treatment"

section of this manual

Cold water temperature too

warm.

See "Tower Operation."

Entering wet bulb temperature is above design

Check to see if local heat sources are affecting cooling tower. See if

surrounding structures are causing recirculation of tower discharge air.

Discuss remedy with Marley representative.

Design wet bulb temperature was too low.

May have to increase cooling tower size. Discuss remedy with Marley

representative

Actual process load greater than design

May have to increase cooling tower size. Discuss remedy with Marley

representative

Overpumping

Reduce water flow rate over cooling tower to design conditions.

Cooling tower starved for air

Check motor current and voltage to be sure of correct contract

horsepower. Clean fill and eliminators. Check to see if nearby structures

or enclosing walls are obstructing normal airflow to cooling tower.

Discuss remedy with Marley representative.

Excessive drift exiting cooling

tower

Faulty drift elimination

Check to see that eliminators are clean, free of debris and installed

correctly. Replace damaged or worn out eliminators panels.

Water leaking from fan scroll

Water level in tower too high

Adjust water level to correct height

Multiple fan motors serving a single fill section not

being cycled simultaneously

Ensure all fans are operating simultaneously and at the same speed