Starting cold engine, Maintenance intervals, Maintenance – Shindaiwa HT231 User Manual

Page 13

13

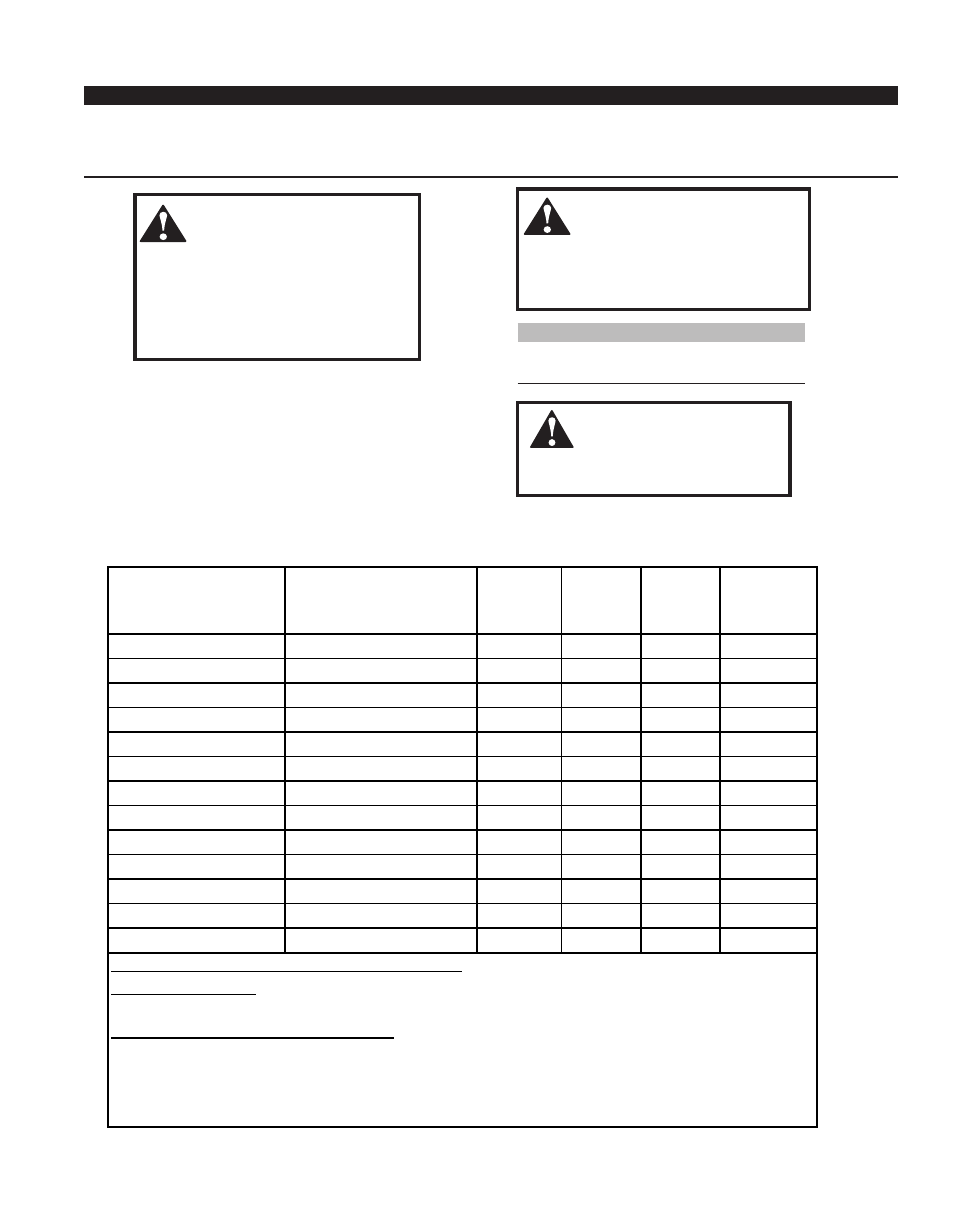

Maintenance Intervals

IMPORTANT!

Maintenance, replacement or repair of emission control devices and systems may be performed by any repair establishment

or individual, However, warranty repairs must be performed by a dealer or service center authorized by Echo, Inc. The use

of parts that are not equivalent in performance and durability to authorized parts may impair the effectiveness of the emis-

sion control system and may have a bearing on the outcome of a warranty claim.

Maintenance

WARNING!

Non-standard parts may not operate

properly with your unit and may cause

damage and lead to personal injury.

NOTE:

Using non-standard replacement parts

could invalidate your Shindaiwa warranty.

WARNING!

Before performing any maintenance,

repair or cleaning work on the unit, make

sure the engine is completely stopped.

Disconnect the spark plug wire before

performing service or maintenance work.

WARNING!

Always wear gloves

when working around the cutter

assembly.

COMPONENT/SYSTEM

MAINTENANCE

PROCEDURE

DAILY OR

BEFORE

USE

EVERY

REFUEL

3 MONTHS

OR 90

HOURS

YEARLY 600

HOURS

Air Filter

Inspect/Clean

I / C *

R *

Choke Shutter

Inspect/Clean

I / C

Fuel Filter

Inspect/Replace

I *

I / R *

Fuel Cap Gasket

Inspect/Replace

I *

R *

Fuel System

Inspect/Replace

I (3) *

I (3) *

Spark Plug

Inspect/Clean/Replace

I / C / R *

Cooling System

Inspect/Clean

I / C

Muffler Spark Arrestor

Inspect/Clean/Replace

I / C / R *

Cylinder Exhaust Port

Inspect/Clean/Decarbon

I / C

Gear Housing

Grease

I (1)

Blades

Inspect/Clean

I / C (2)

Recoil Starter Rope

Inspect/Clean

I / C *

Screws/Nuts/Bolts

Inspect/Tighten/Replace

I *

* All recommendations to replace are based on the finding of damage or wear during inspection.

(2) Inspect blade and clean as needed. Lubricate blades periodically during use.

(3) Low evaporative fuel tanks DO NOT require regular maintenance to maintain emission integrity.

MAINTENANCE PROCEDURE LETTER CODES: I = INSPECT, R = REPLACE, C = CLEAN

IMPORTANT NOTE - Time intervals shown are maximum. Actual use and your experience will

determine the frequency of required maintenance.

MAINTENANCE PROCEDURE NOTES:

(1) Apply Grease every 20 hours of use.