Xiv. troubleshooting – Woodstock W1099 User Manual

Page 16

- 15 -

Woodstock Intl., Inc. W1099

XIV. TROUBLESHOOTING

E. FIT TOO TIGHT

OR TOO LOOSE

If you find the fit to be about right in every other

aspect, but it is simply a little too tight or too

loose, the depth of the router bit is probably mal-

adjusted.

1. If the fit is too tight, decrease the protrusion

of the router bit from the base.

2. If the fit is too loose, increase the protrusion

of the router bit from the base.

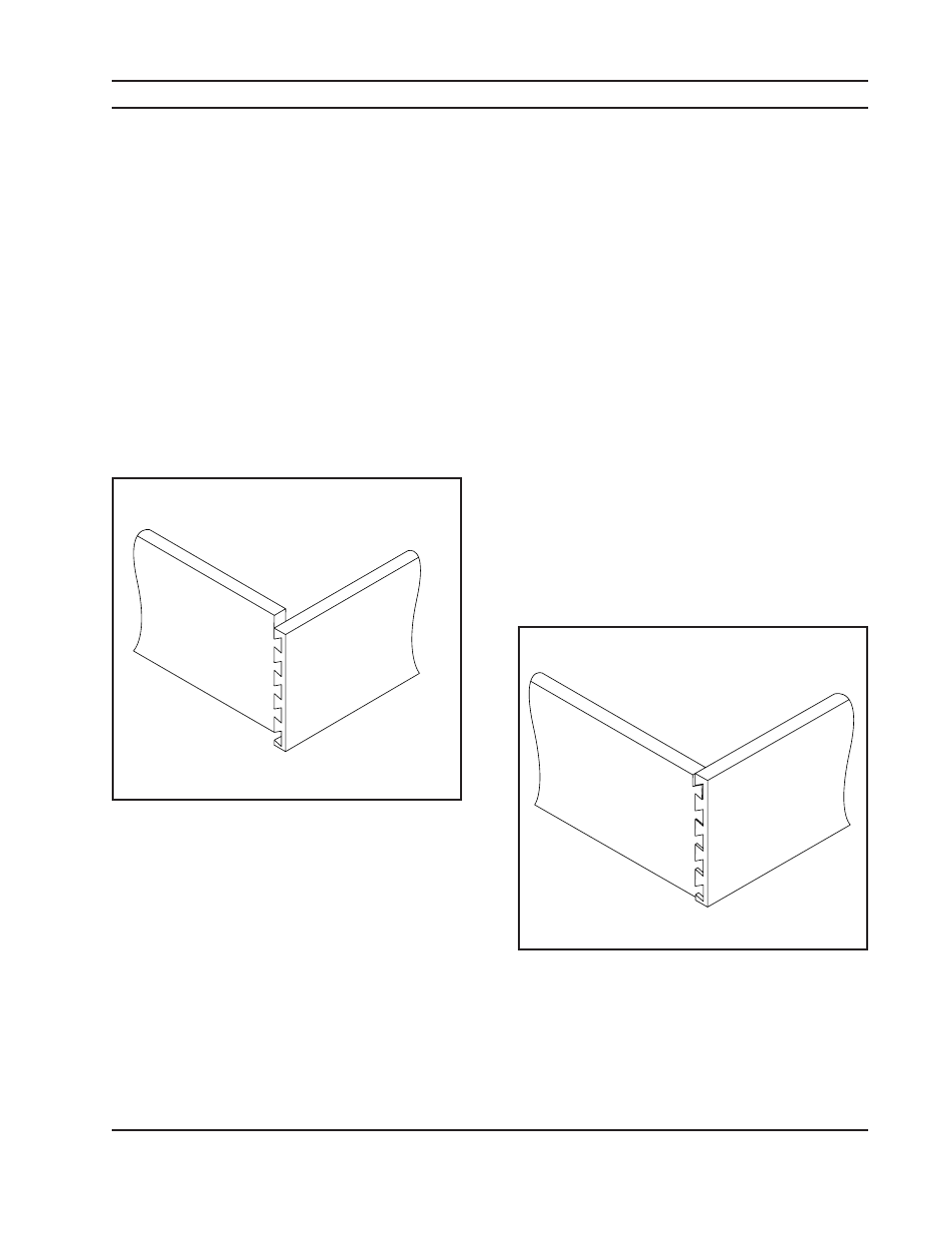

D. OFFSET EDGES

If the side piece edge is not aligned with the front

or back piece edge, the edges are offset. Figure

18.

Cause: The side stops are not set correctly.

Remedy: Measure the amount of offset on the two

test pieces and adjust the front side stop accord-

ingly. The front side stop must be offset from the

top side stop by the exact width of the fingers on

the template you are using. Ensure that the front

side stop remains square to the workpiece mounted

on top of the jig.

F. UNEVEN FIT

If the side piece fits either excessively or protrudes

at one edge and not the other, the fit is uneven.

Figure 19.

Cause: The fence is not parallel to the edge of the

workpiece or the template is not parallel to the

edge of the workpiece.

Remedy: Adjust the fence or template in the

desired direction until it is parallel to the edge of

the workpiece. For the highest degree of accuracy,

clamp the two workpieces in the front of the jig

so they are positioned against the two side stops

and measure the distance between the edge of the

workpiece and the edge of the fence or template.

Adjust the fence or template so the measurement

on the other end of the jig equals the first. Re-

check the first measurement in case it changed

during adjustment.

Figure 19 shows uneven fit.

Figure 18 shows offset edges.