Driveshaft/powerhead all models, Assembly, Assembly handle – Shindaiwa T230 User Manual

Page 6

6

Driveshaft/Powerhead All Models

Grip

Spark Plug

Main

Shaft

Tube

Clamp

Outer Tube

T230

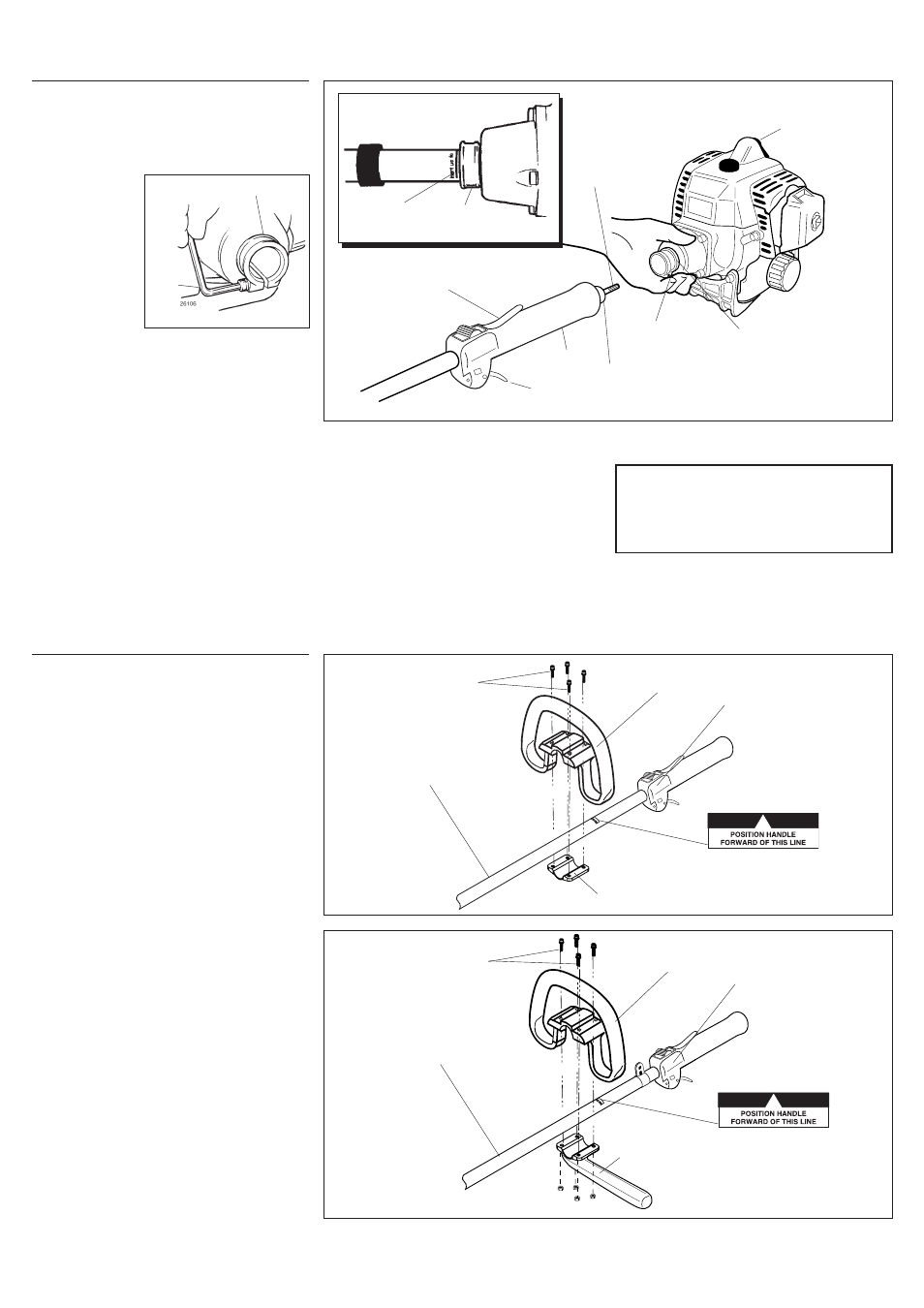

1. Place the powerhead on a clean, flat sur-

face, spark plug facing up. See Figure 6.

2. Use the

4 mm hex

wrench to

loosen the

tube clamp

screw.

3. Add some

moly-type

EP grease to

the splines

on the end of the mainshaft.

4. Slide the outer tube into the tube clamp

until the tube bottoms. If installation is

difficult, rotate the outer tube or main-

shaft slightly until you feel the mainshaft

splines engage with the powerhead.

5. Position the outer tube so that the igni-

tion switch is facing up and the throttle

trigger is down.

Tube Clamp

Connect the Outer Tube

to the Powerhead.

CAUTION!

Do not force the shaft tube into the

powerhead! Excessive force can dam

age the shaft tube and mainshaft.

Clamp must fit next to line

on outer-tube decal

Decal

Clamp

C230 Brushcutter

Clamp

Screw

Figure 6

Figure 5

Assembly

Throttle

Trigger

Ignition

Switch

Hex

Wrench

Figure 6A

T230 Slide the outer tube into the

powerhead until the throttle grip

just contacts the tube clamp.

C230 Slide the outer tube into the

powerhead until the installation

decal aligns with the tube clamp.

See Figure 6A.

6. Tighten the clamp screw firmly.

Assembly

Handle

T230 - Connect the Handle to

the Outer Tube.

1. Position the handle on the outer tube

forward of Handle Positioning Label as

shown in Figure 7.

2. Install the mounting bracket with the

socket head cap screws. Tighten the

screws finger-tight ONLY at this time.

3. Locate the handle in the best position

for operator comfort (usually about 10

inches ahead of the throttle housing).

4. Secure the handle by alternately tighten-

ing the four socket-head screws in a

diagonal or “crisscross” fashion.

Outer Tube

Socket-head

Caps Screws

Handle

Mounting Bracket

Throttle

Assembly

Figure 8

Handle Positioning Label

T230X - Connect the Handle to

the Outer Tube.

1. Position the handle on the outer tube

forward of Handle Positioning Label as

shown in Figure 8.

2. Install the barrier bar with the socket

head cap screws and nuts. Tighten the

screws finger-tight only at this time.

3. Locate the handle in the best position

for operator comfort (usually about 10

inches ahead of the throttle housing).

4. Secure the handle by alternately tighten-

ing the four socket-head screws in a

diagonal or “crisscross” fashion.

Figure 7

Outer Tube

Socket-head

Caps Screws

Handle

Barrier

Throttle

Assembly

Handle Positioning Label