Operational tips, Operations – Woodstock International Shop Fox W1683 User Manual

Page 28

26

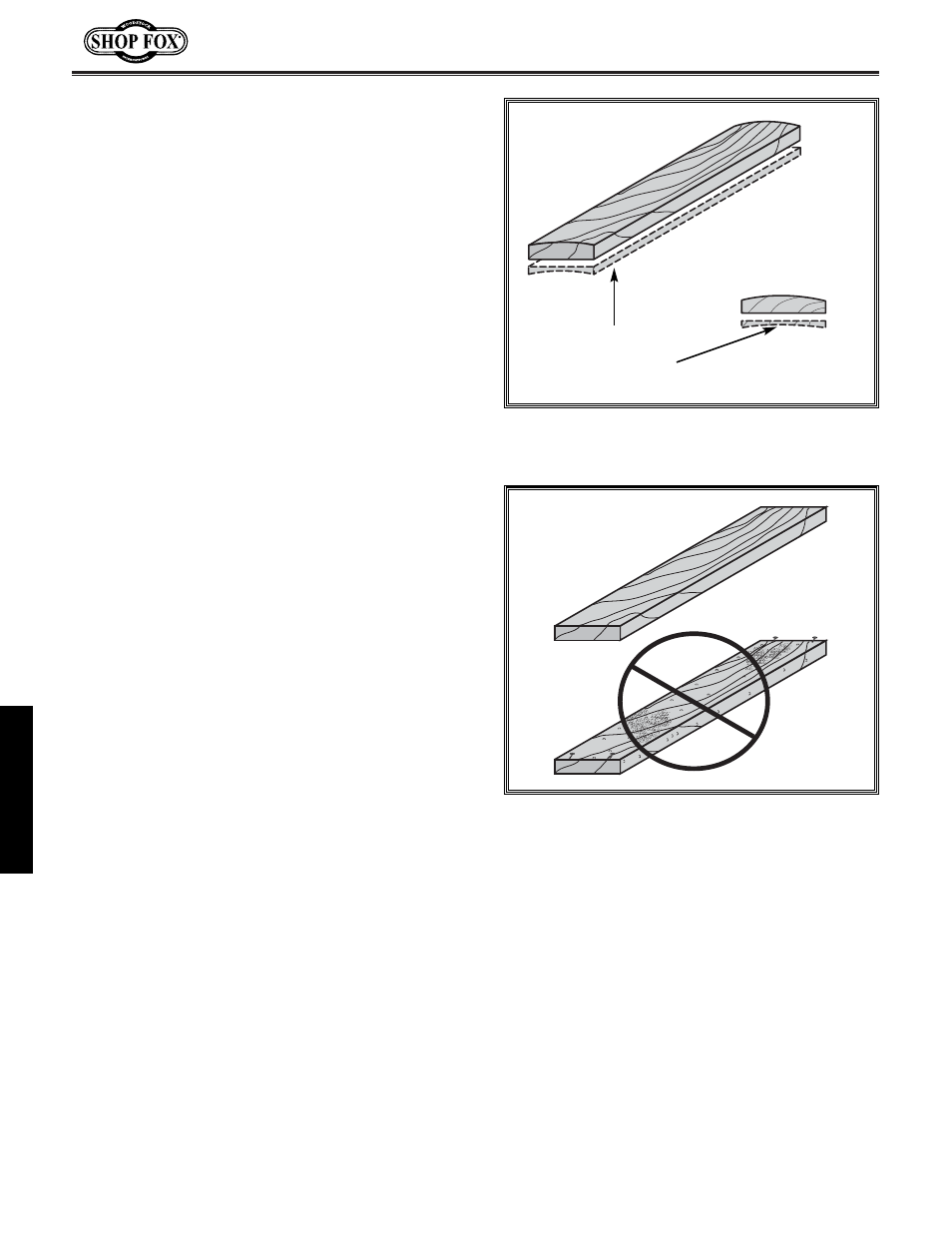

Figure 32. Face joint the concave side of cupped

stock before planing.

Figure 33. Only plane clean stock.

Operational Tips

•

Carefully inspect any lumber that you plan

to run through the planer. Each board must

have at least one flat surface to slide along

the planer table. To create a flat surface,

pass the stock over a jointer first. See

Figure 32. Some defects such as moderate

twisting, loose knots or severe cracks may

make the stock unusable.

•

Only use clean stock. See Figure 33. Scrape

off all glue from joined boards before

planing. Remove all dirt, nails, staples,

imbedded gravel, etc. from any lumber you

plan on using. A hidden nail in a workpiece

will instantly damage the sharp edges of the

knives. This will cause unsatisfactory results

in future operations.

•

Plane ONLY natural wood fiber. Never plane

wood composites such as particle board,

plywood or MDF. Never plane laminates,

formica or other synthetic materials.

•

Surface wood in the same direction as the

grain. Never feed end-cut or end-grained

lumber into the planer.

•

Keep your work area clear. Always make

sure that long workpieces are supported and

have enough room to exit the planer.

•

When making multiple passes with long

stock, use the top rollers to move material

back to the infeed side of the planer.

•

Avoid planing wood with a high moisture

content. Stock with more than 20%

moisture, or stock that has been exposed to

rain or snow, will plane poorly and cause

unnecessary wear on the knives and motor.

Excess moisture may also cause rust or

corrosion problems.

Portion

Removed With

Jointer

OPERATIONS