Maintenance (continued) – Shindaiwa Articulated Hedge AH242 User Manual

Page 17

17

Maintenance (continued)

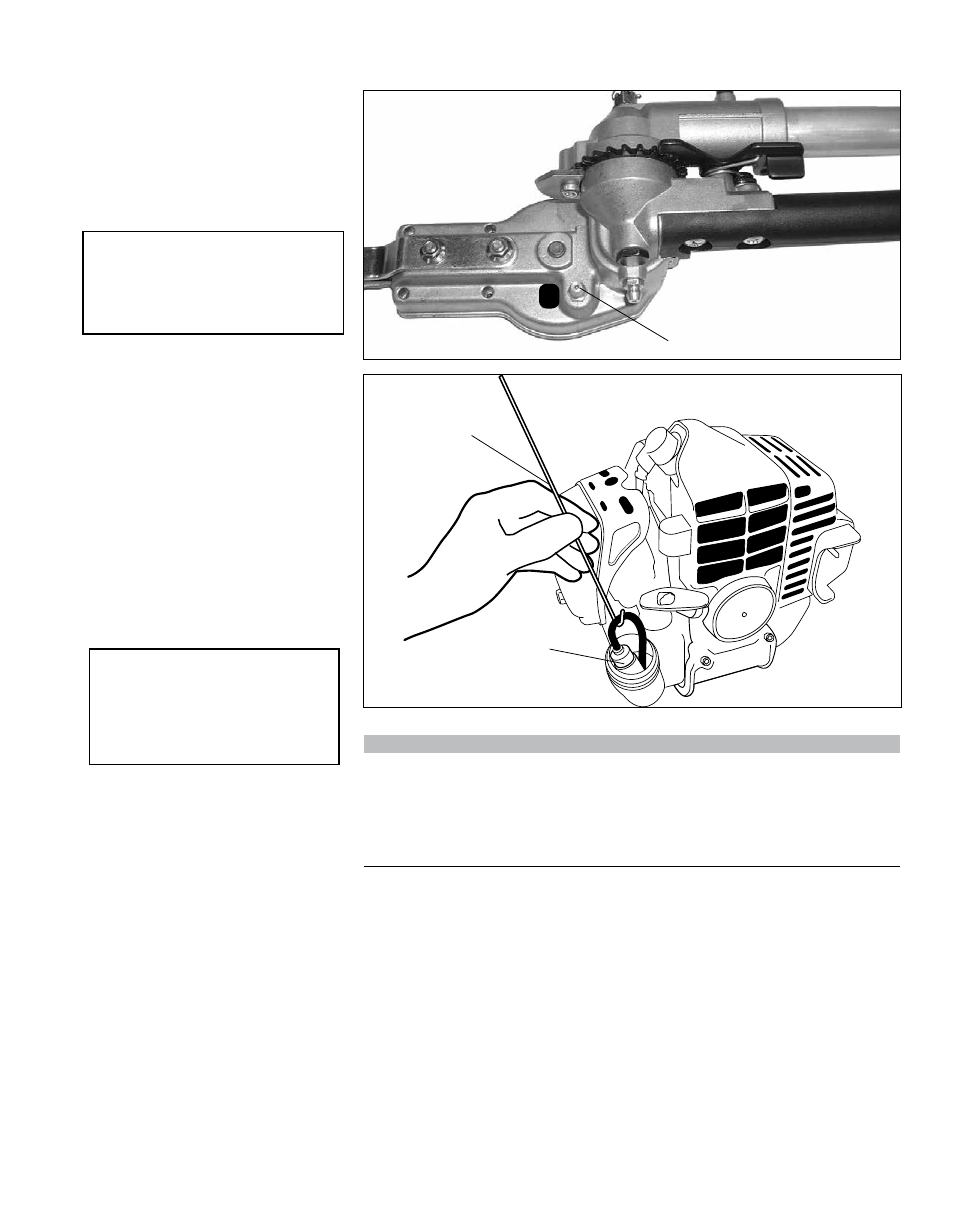

Lubricate cutter assembly and gearcase

Gearcase

grease fitting

A

■

Lubricate the cutter assembly

gearcase by pumping one or two

strokes of lithium-base grease into

the grease fitting (A) using a lever-

type grease gun.

CAUTION!

Over lubricating can cause the

gearcase to operate sluggishly

and can cause grease to leak out.

Gearcase lubrication

Hooked wire

Fuel filter element

Remove and replace the fuel filter element

50-hour maintenance

Every 50 hours of operation; more

frequnetly in dusty conditions:

■

■

■

Remove and clean the cylinder

cover and clean dirt and debris

from the cylinder cooling fins.

Remove and replace the fuel filter

element.

■

Use a hooked wire to extract the

fuel filter from inside the fuel tank.

Inspect the fuel filter element. If

it shows signs of contamination,

replace with a genuine Shindaiwa

replacement fuel filter element.

CAUTION!

Make sure you do not pierce the

fuel line with the end of the hooked

wire. The line is delicate and can

be damaged easily.

■

Before reinstalling the new filter

element, inspect the condition of

all the fuel system components

(fuel pick-up line, fuel return line,

tank vent line, tank vent, fuel cap

and fuel tank). If damage, splitting

or deterioration is noted, the unit

should be removed from service

until it can be inspected or repaired

by a Shindaiwa-trained service

technician.

NOTE:

Federal EPA regulations require all model year 2012 and later gasoline powered

engines produced for sale in the United States to be equipped with a special low

permeation fuel supply hose between the carburetor and fuel tank. When servic-

ing model year 2012 and later equipment, only fuel supply hoses certified by EPA

can be used to replace the original equipment supply hose. Fines up to $37,500

may be enforced for using an un-certified replacement part.