Plumbing connections, hose layouts, Clamp connections, Solvent bond connections – SeaLand BASIC HOLDING TANK SYSTEM User Manual

Page 4: Installation (cont’d)

4

INSTALLATION (cont’d)

PLUMBING CONNECTIONS AND HOSE LAYOUTS

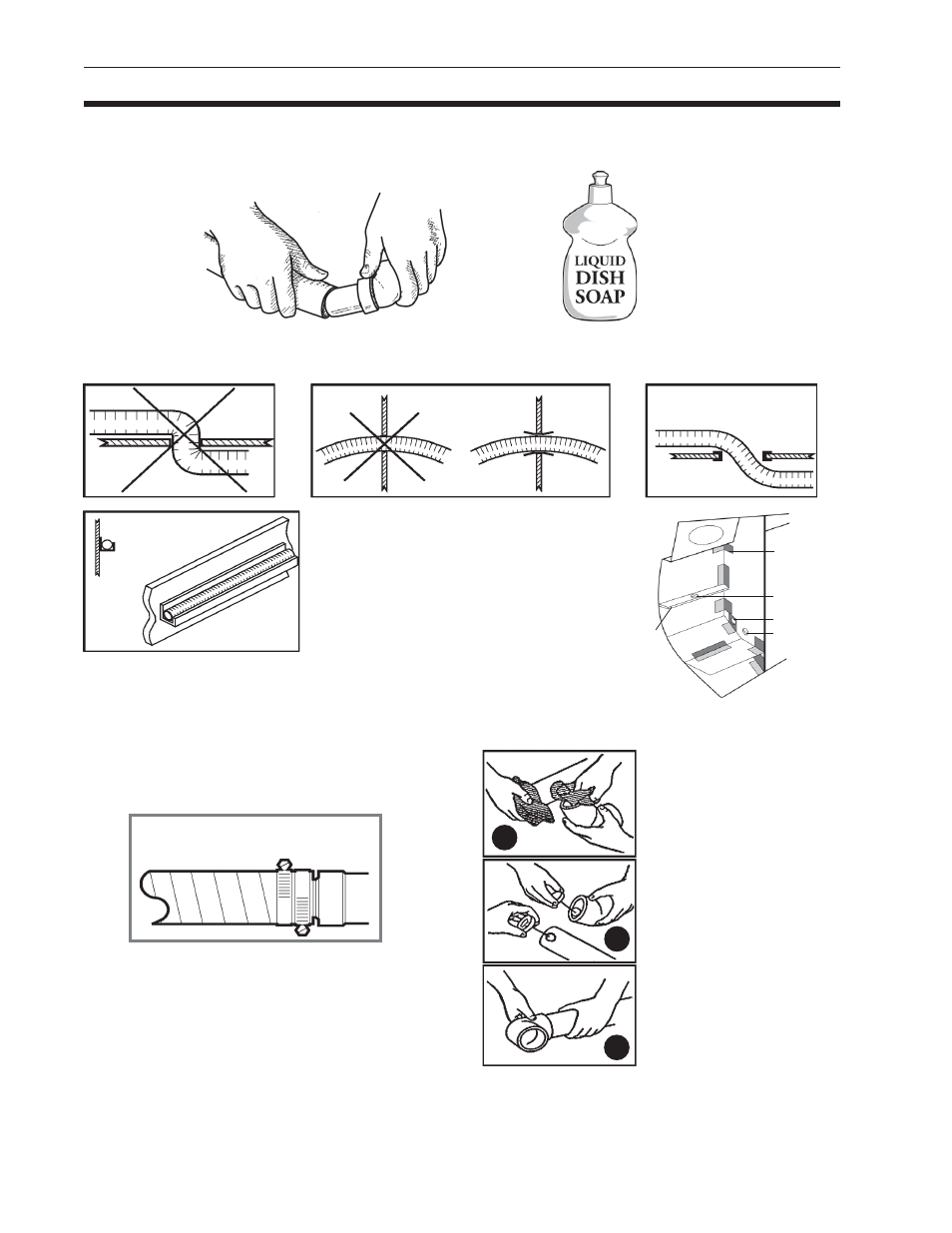

When connecting flexible hose to plastic fittings, use liquid dish soap on end of

fitting and inside hose end to make connection easier.

Do not use any other lubricants, sealants or adhesives when connecting sanitation hoses and fittings.

Do not restrict the ability to pull the hose or pipe.

EXCELLENT

Avoid binding corners and sharp bends.

Do not use wire ties to secure the hose

or pipe.

Support flexible hose every 12 inches

(.3 m), and support rigid pipe every 5 feet

(1.5 m).

When creating new holes, avoid

reinforcement stringers and tabs.

YES

YES

Trough

support

SOLVENT BONDING FOR RIGID PIPE AND FITTINGS

1. Use PVC cleaner on both

bonding surfaces.

2. Use PVC cement (must

contain tetrahydrofuran) on

both bonding surfaces.

3. Connect parts using a twist

and hold motion until the

cement is set.

4. Let the joint cure for at least

four hours or according to

instructions on PVC cement

container. (Cold tempera-

tures require longer cure

times.)

1

2

3

Position clamp screws 180° apart from

each other and tighten clamps.

CLAMP CONNECTIONS FOR FLEXIBLE HOSE AND

FITTINGS

Dometic recommends that each hose connection be

secured with two hose clamps to prevent any leaks.

STRINGER

TABS

AVOID

AVOID

YES