Venting, Vertically vented unit heaters (category i) – Sterling TF-300 User Manual

Page 12

12

VENTING

Observe the following precautions when venting the unit:

1. Use flue pipe of the same size as the flue

connections on the gas unit heater (See Table #1).

All heaters should be vented with UL Listed Type

B vent, a factory built chimney, or a lined brick

and mortar chimney that has been constructed in

accordance with the National Building Code.

2. Provide as long a vertical run of fl ue pipe at the gas

unit heater as possible. A minimum of 5 feet (1.5m)

of vertical fl ue is required. The top of the vent pipe

should extend at least 2 feet (0.61m) above the

highest point on the roof. Install a weather cap over

the vent opening.

3. Slope horizontal runs upward from the gas unit

heater at least 1/4-inch per foot (21mm/m) minimum.

Horizontal runs should not exceed 75% of the

vertical height of the vent pipe, or chimney, above

the fl ue pipe connection, up to a maximum length

of 10 feet (3m). Horizontal portions of the venting

system shall be supported at maximum intervals of

4 feet (1.2m). (See Figure 6)

4. Use as few elbows as possible.

5. Tape

fl ue pipe joints with high-temp, RTV or foil face

tape.

6. Avoid running vent pipe through unheated spaces.

7. When this cannot be avoided, insulate the pipe to

prevent condensation of moisture on the walls of the

pipe.

8. Do not damper the fl ue piping. Failure to open such

a damper prior to operating the gas unit heater will

result in the spillage of flue gas into the occupied

space.

9. Avoid installing units in areas under negative

pressure due to large exhaust fans or air conditioning.

When required, a fl ue vent fan should be installed in

accordance with the instructions included with the

fan.

10. Vent connectors serving Category I and Category

II heaters shall not be connected into any portion of

mechanical draft systems operating under positive

pressure.

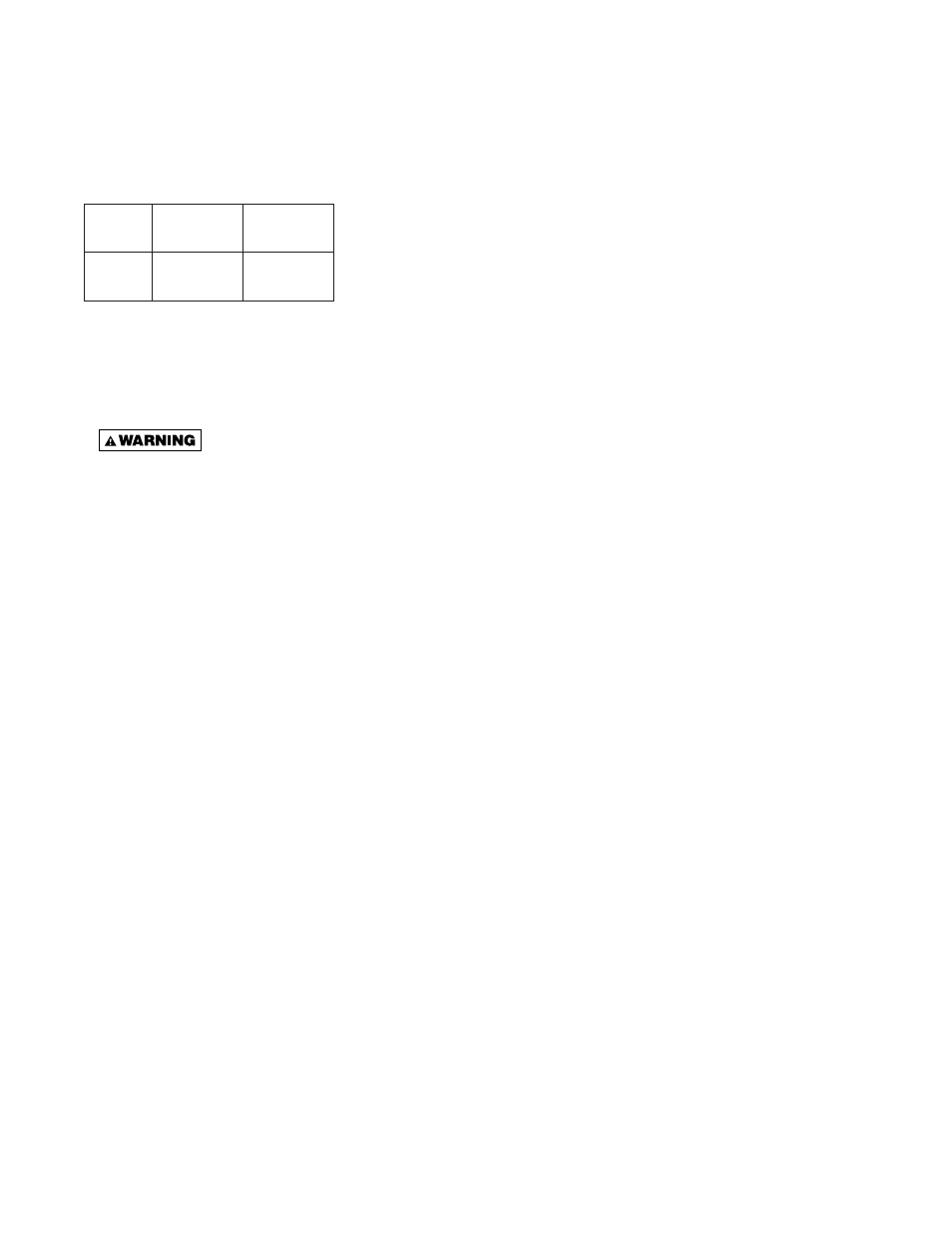

ANSI now organizes vented

appliances into four categories.

Venting Categories

Non

Condensing

Condensing

Negative

Vent

I

II

Pressure

Positive

Vent

III IV

Pressure

VERTICALLY VENTED UNIT HEATERS (CATEGORY I)

Category I

Includes non-condensing

appliances with negative vent

pressure, like the traditional

atmospheric unit heater.

Category II

Groups condensing appliances

with negative vent pressure.

Category III

Appliances are non-condensing

and operate with a positive vent

pressure.

Category IV

Covers condensing appliances with

positive vent pressure.

NOTICE: Category II and IV do

not apply to equipment specifi ed

within this manual.

All unit heaters must be vented! All Venting installations shall be in accordance with the latest edition of Part 7,

Venting of Equipment of the National Fuel Gas Code, ANSI Z223.1, or applicable provisions of local building codes.

Refer to page 15 for Canadian installations. Refer to Figures 6, 7, 8A, 8B, 9A and 9B.

CARBON MONOXIDE! Your venting system must not be blocked by any snow, snow

drifts, or any foreign matter. Inspect your venting system to ensure adequate ventilation exists at all

times! Failure to heed these warnings could result in Carbon Monoxide Poisoning (symptoms include

grogginess, lethargy, inappropriate tiredness, or fl u-like symptoms).