SoundCraft CPS2000 User Manual

Page 40

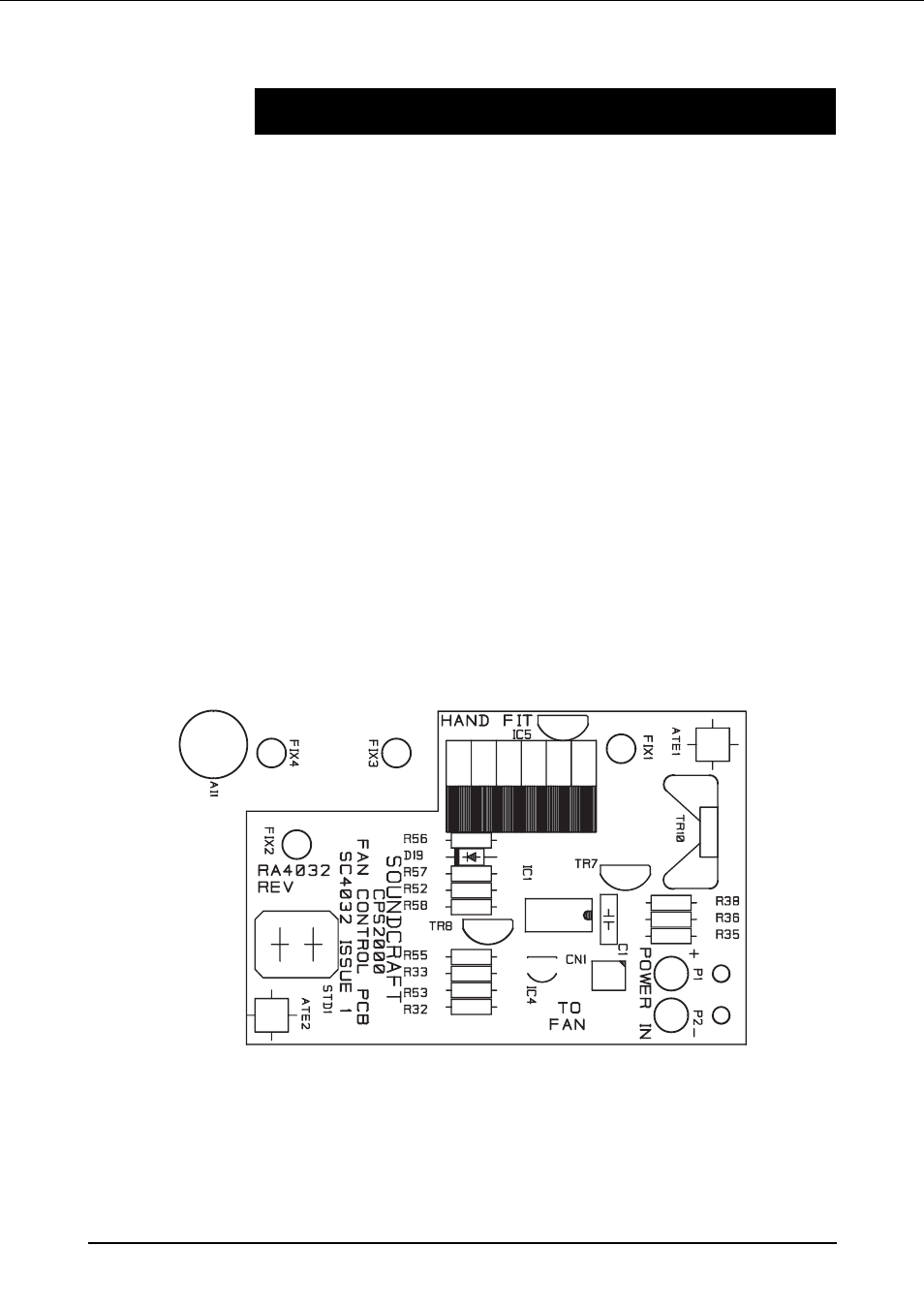

CPS2000 Fan Control & PCB SC4032

Technical Description

The later models of the CPS2000 are fitted with a fan control servo system that adapts the fan

speed to the power drawn. This gives a substantial reduction in fan noise under almost all

circumstances; the exception being 10% high mains and maximum current drawn, which

naturally sets the fan to full speed. The PCB (with associated mounting bracket) may be

retrofitted to existing CPS2000 units.

The servo circuit consists of opamp IC1-A, temperature sensor IC5, shunt regulator IC4, and

fan control devices TR7,TR10. IC4 maintains 2.50V between its "anode" and "cathode"; this is

the precise voltage that drives the reference chain R53,55. TR8 also uses this voltage to set its

emitter at 4.4V above ground; this keeps IC1’s inputs within their common-mode range. Thus

both ends of the voltage divider R53-R55 are fixed at defined voltages. LM35DZ temperature

sensor IC5 outputs 10mV per degreeC above freezing point (0 degC) and applies it to IC1-A

non-inverting input. The desired heatsink temperature is set at the junction of R53,55, which

sits at +5.0V approx. This is 600mV above the +4.4V rail, and so represents 60 degC. R52,57

set the servo loop gain. This is designed to be safely below the level at which slow thermal

oscillations would occur. R56,D19 increase the loop gain when IC1-A output is below 4V. This

prevents the fan sitting for long periods in a not-quite-running state where it consumes current

but does not rotate.

The voltage range 1-4V where this occurs is thus skipped over quickly. The fan is driven through

feedback amplifier TR7,10, which has a voltage gain of 1.3 times. This allows the fan to be

driven over its full operating voltage range despite the output saturation limits of IC1-A. This

gives improved cooling at high temperatures and mains voltages. The CPS2000 thermal

shutdown system is quite separate and has no connection with this PCB.

36

Fan Control