Maintenance (continued) – Shindaiwa PowerBroom PS344 User Manual

Page 15

15

Maintenance (continued)

Gearcase Lubrication

The gearcase should be filled with 60 cc

(2.0 fl.oz.) of Mobil SHC634 Synthetic

Gear Oil. A maximum of 75-80 cc can be

used, but never to exceed 80 cc. Opera-

tion with excessive oil level will result

in high operating temperatures.

Do not

overfill!

Turn the gearcase to the LH side

4.

and and allow all used gearcase oil

to drain into a small container.

Place the gearcase on the RH side

5.

and supported so the outer tube

is parallel to the ground. Refill the

gearcase with 60 cc (2.0 fl.oz) of

Mobil SHC634 Synthetic Gear Oil

to the bottom of the chamfer on

the output gear. The correct oil

depth is 5/8" (15.5 mm). DO NOT

OVERFILL!

WARNING!

BURN DANGER! The

gearcase will be extremely hot after

use!

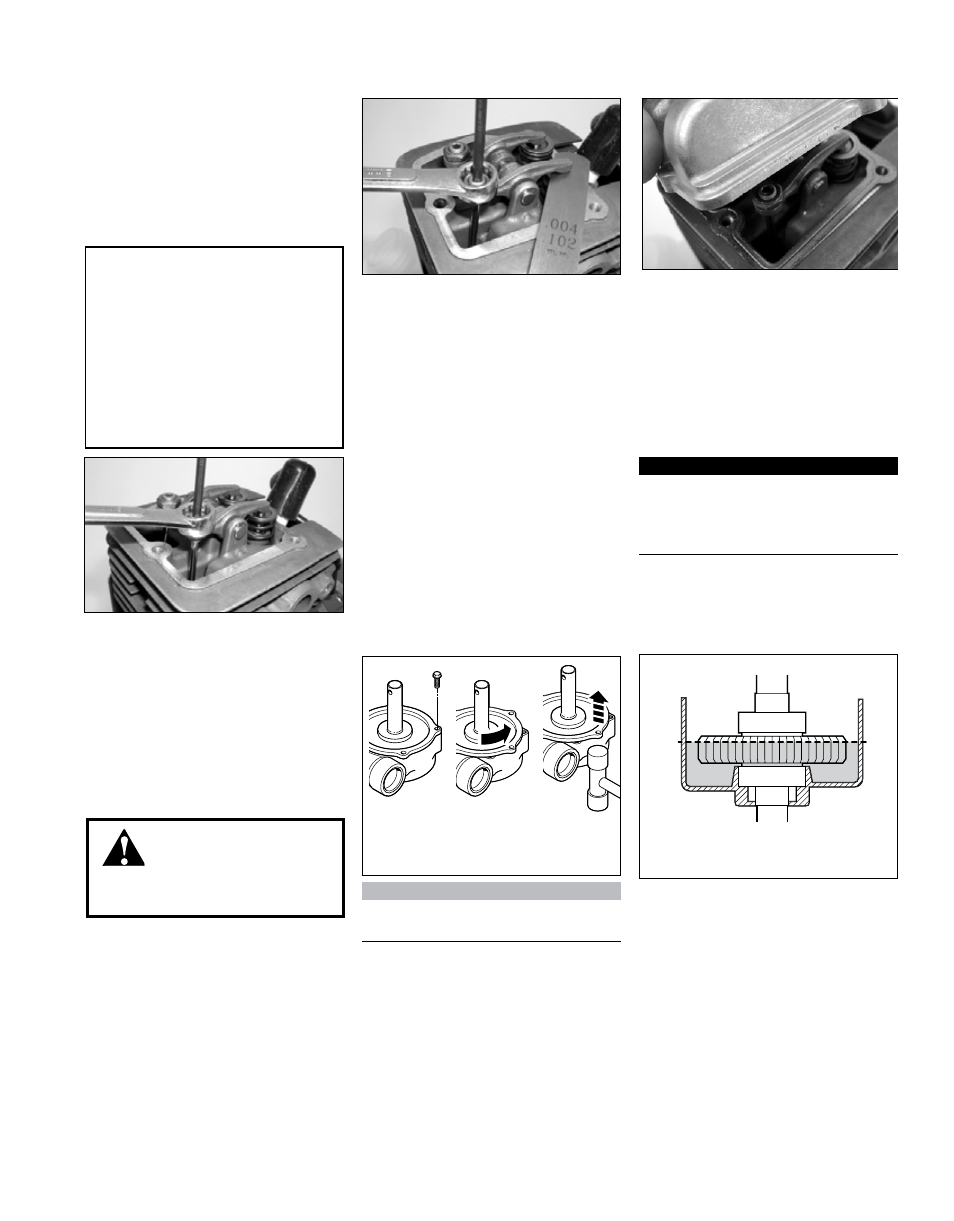

Replacing the gearcase oil

Disconnect spark plug wire at

1.

engine.

Remove the LH Drum and axle

2.

assembly (as viewed from the operat-

ing position). Wipe the sideplate

clean and remove four screws (it

is not necessary to remove the

gearcase from the outer tube).

Turn gearcase side plate to break

3.

the seal and lift the plate from the

gearcase.

Inspect the sideplate for damage and

6.

clean off all remaining liquid gasket

material with brake cleaner or ace-

tone. Coat the outer sealing flange of

the sideplate with silicon sealant.

Replace the cover and install the

7.

four sideplate screws. Tighten

securely.

Reinstall the drum and axle assem-

8.

bly. Refer to the section “Assembly:

Sweeper Assembly” for instructions.

300-hour maintenance

iMPORTanT!

If a new gasket is not available and/

or the old gasket is not damaged, the

old gasket may be reused. Never use

cracked or damaged gaskets!

Turn engine over several times,

6.

and return to TDC-compression.

Recheck with proper feeler gauge to

make sure clearance adjustment did

not change as a result of tightening

the locknut. Readjust as necessary.

Replace rocker arm cover gasket

7.

to assure proper sealing and install

cover.

Valve Adjustment

Remove cylinder cover, rocker arm

1.

cover, and spark plug. Rotate the

crankshaft while observing the piston

through the spark plug opening.

When the piston is at the top of the

compression stroke (TDC), the valves

can be adjusted.

Loosen adjuster locknut so that the

2.

2.5 mm Allen socket head adjustment

screw can turn freely.

Insert 0.10 mm (0.004”) feeler gauge

3.

between valve stem tip and rocker

arm.

Turn adjustment screw (clockwise =

4.

tighter, counter-clockwise = looser)

until feeler gauge is almost snug.

Back off just enough to allow gauge

to slip out with limited resistance.

While holding the adjustment screw

5.

in place with the Allen driver, tighten

the locknut with a wrench.

CaUTiOn!

Performing a valve adjustment

■

incorrectly may cause hard

starting and/or can damage the

engine.

If you are unfamiliar with this

■

engine or uncomfortable with

this procedure, consult with an

authorized Shindaiwa servicing

dealer.

135 hour maintenance (cont.)

Turn gearcase side plate to break the seal

and lift the plate from the gearcase

Fill the gearcase to the bottom of the

chamfer on the output gear.

DO NOT OVERFILL!

nOTE:

It may be necessary to use a heat gun

to soften the sealer material.