Blower prover failure, Blower prover open, Blocked air intake – State Industries ULTRA FORCE 101 User Manual

Page 63: Energy cut out (eco)

63

fault and alert messages (cont)

Call the technical support phone number listed on the back cover for further technical assistance or to locate a qualified service agent

in your area.

possible causes - check/repair

displayed fault/alert message

• The control system has detected the blower Prover Switch

contacts are closed when they should be open at the beginning of

a heating cycle - see the Sequence Of Operation on page 58.

• Pinched/shorted blower Prover Switch wiring - see beginning on

• Jumper wire connected to the blower Prover Switch - remove

jumper wire. Jumper wires must never be used, read all Warnings

• Excessive wind outdoors pressurizing the vent system piping.

• Excessive negative air pressure in the installed space.

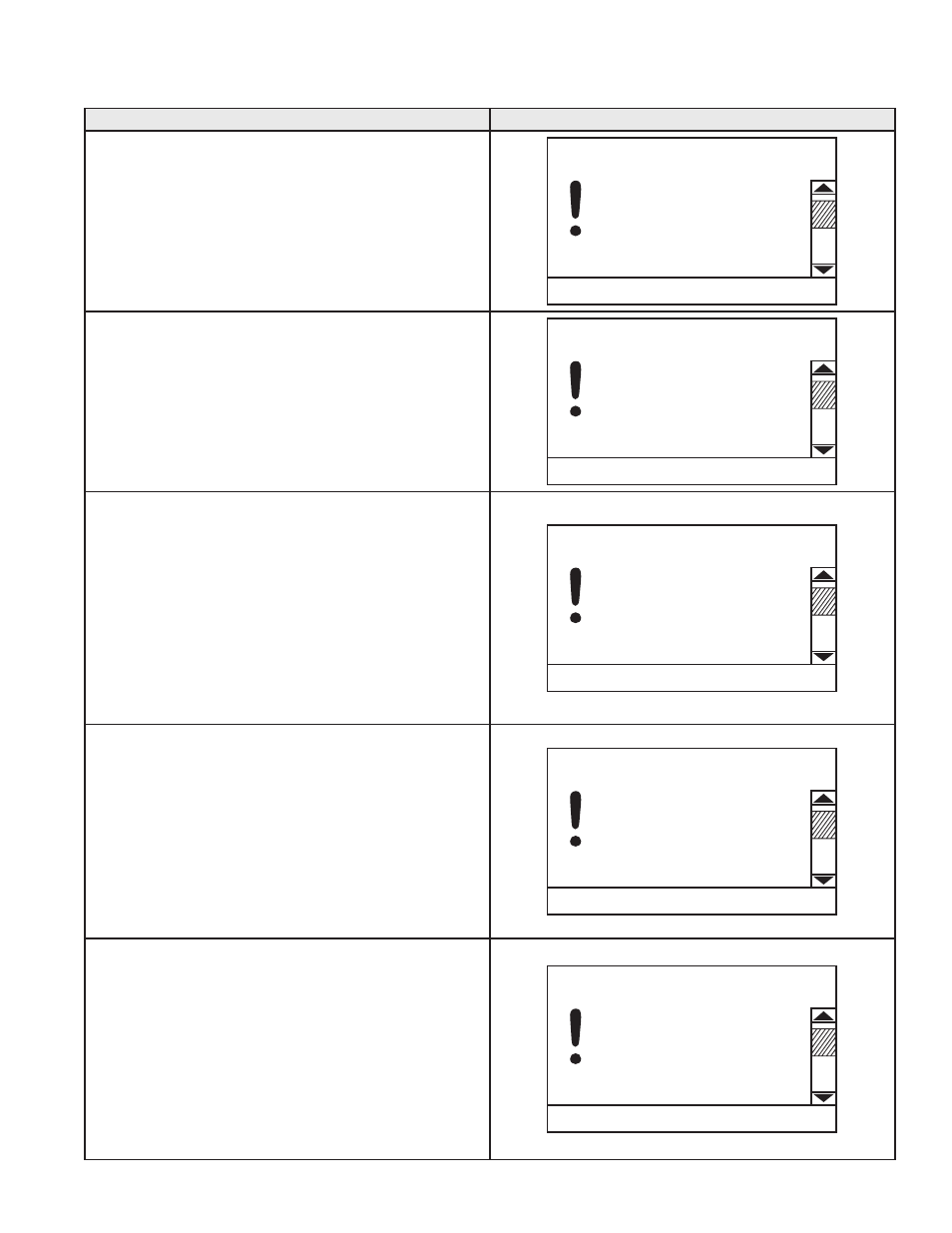

CHANGE

BACK

ADVANCED

Blower Prover Failure

Fault occurred 2 mins ago

The blower prover switch is

closed out of sequence.

Call a service professional:

Your Company Name Here

(press [DOWN] for more....)

• The control system has detected the blower Prover Switch

contacts are remaining open after the control system has

energized the Combustion blower - see the Sequence Of

• Loose or open wiring to the blower Prover Switch - see beginning

on page 8 for switch location.

• blower Prover Switch air sensing tube disconnected, kinked, filed

with condensate, damaged or leaking - repair or replace tube.

• Combustion blower is not running when energized.

• Loose or open wiring or plug connections to Combustion blower.

CHANGE

BACK

ADVANCED

Blower Prover Open

Fault occurred 2 mins ago

The blower prover switch remains

open after the blower has been

energized.

Call a service professional:

Your Company Name Here

(press [DOWN] for more....)

• The control system has detected the blocked intake Air Switch

contacts are open.

• Loose or open wiring to the blocked intake Air Switch - see

beginning on page 8 for switch location.

• Excessive equivalent pipe length, exceeded the maximum number

of 90° elbows or wrong pipe size used in the intake air piping

system - see Venting requirements on page 24.

• intake air screen was not removed prior to connecting the intake

air piping to the water heater and is clogged/blocked with debris -

• SUF 199 & 250 models only; condensate has drained into the

blocked intake Air switch through the sensing tube, see SUF 199 &

SUF 250 intake Air Connection on page 23.

• Excessive negative air pressure in the installed space.

CHANGE

BACK

ADVANCED

Blocked Air Intake

Fault occurred 2 mins ago

The combustion air intake is

restricted.

Call a service professional:

Your Company Name Here

(press [DOWN] for more....)

• The control system has detected the ECO (energy cut out) Switch

contacts are open.

• The ECO switch is a normally closed switch that opens on a

temperature rise to prevent excessive water temperature in the

storage tank. The ECO switch is inside the Upper Temperature

Probe (two red wires) - see beginning on page 8 for Upper Probe

location.

• Loose or open wiring to the ECO switch in the Upper Temperature

Probe - two red wires.

• improper water system piping and/or excessively high return

(recirculation) loop water temperature - see the Water Piping

Diagrams beginning on page 71.

CHANGE

BACK

ADVANCED

Energy Cut Out (ECO)

Fault occurred 2 mins ago

Tank temperature is excessive.

The water heater has been

disabled.

Call a service professional:

Your Company Name Here

(press [DOWN] for more....)

• The control system has not detected any voltage from the powered

anode rods - see beginning on page 8 for location.

• No water in the storage tank.

• Loose or open wiring connections to the powered anode rods - see

beginning on page 8 for location.

• Powered anode rod wiring shorted to ground.

• The water heater is not properly grounded - see Power Supply

• Loose or open ground wires.

• Top fitting (3/4 inch bushing) of the powered anode rods were

saturated with water during installation - with power to the water

heater turned off, carefully remove anode rods and dry out

bushing(s).

CHANGE

BACK

ADVANCED

No Anode Voltage

Alert:

Alert occurred 2 mins ago

No voltage detected from

Powered Anode(s).

Call a service professional:

Your Company Name Here

(press [DOWN] for more....)