Feed shaft spring tension – Woodstock W1668 User Manual

Page 18

-16-

W1668 13

1

⁄

4

" Oscillating Drill Press

A

D

JU

ST

M

ENT

S

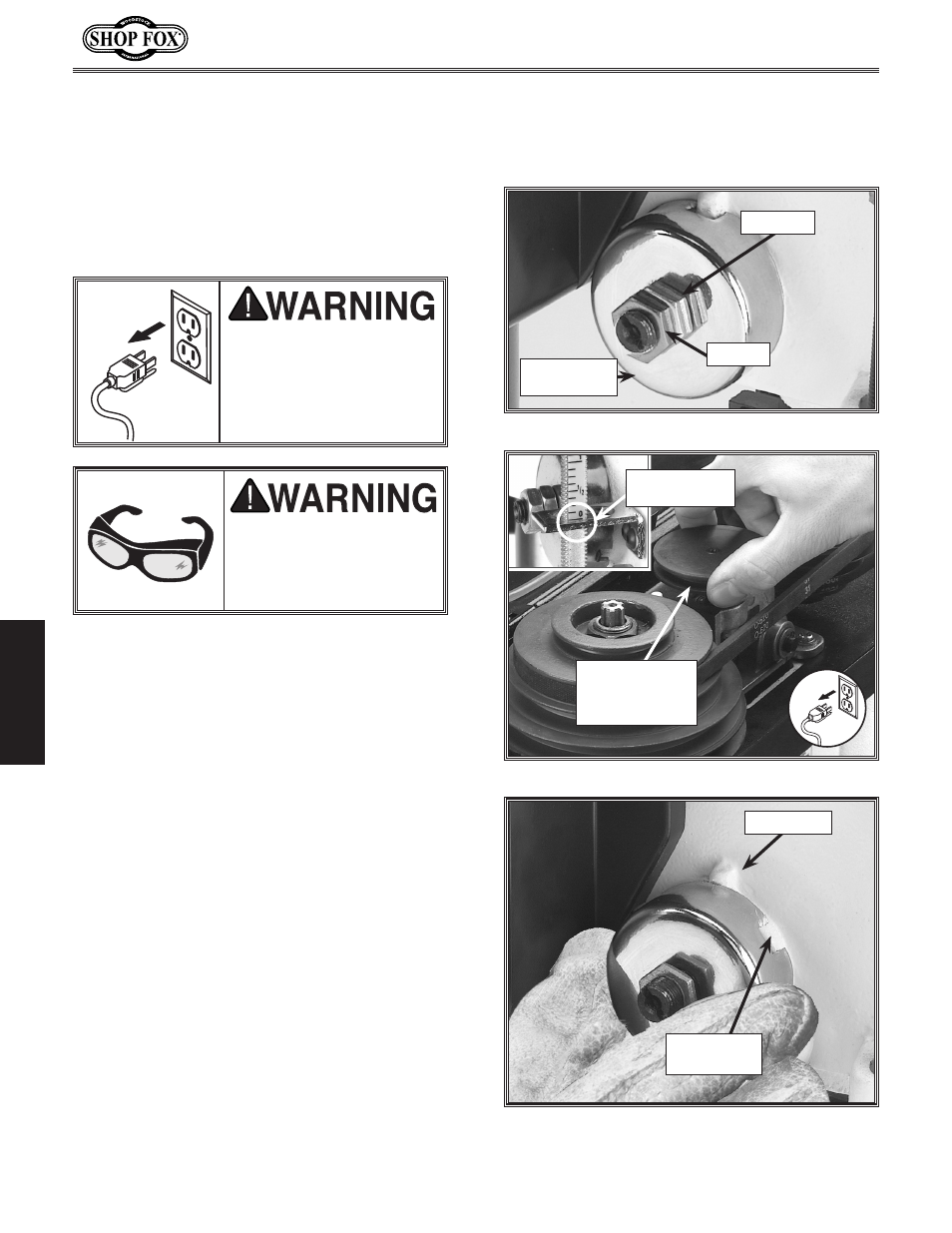

The feed shaft return spring is adjusted at the

factory; however, during the life of the drill

press you may want to adjust the feed shaft

return spring to a stronger return pressure.

To adjust the feed shaft spring tension, do

these steps:

1. UNPLUG THE DRILL PRESS!

2. Wipe off any oil on the spring lock cover so

it will not slip in your fingers when you hold

the cover from spinning (see

Figure 24).

3. Rotate the oscillator pulley so the depth stop

reads “0” and the quill shaft is completely

seated, as shown in

Figure 25.

4. Put on thick leather gloves and hold the

spring cover against the side of the head-

stock, so the cover stays splined with the

locking lug, and remove the jam nut to

loosen the cover nut approximately

1

⁄

4

"

(6.4mm).

5. Pull the cover outward just enough to dis-

engage the spring-cover lock slot from the

locking lug (see

Figure 26).

6. Rotate the cover counterclockwise to

increase spring tension, or let the cover

slowly unwind in the clockwise direction to

reduce spring tension (see

Figure 26).

MAKE SURE your machine is

unplugged during all

assembly, adjustments, or

maintenance procedures.

Otherwise serious personal

injury may occur!

WEAR safety glasses when

adjusting springs. Serious

injury may occur if this

warning is ignored!

Figure 24. Typical feed shaft return spring assy.

Spring Lock

Cover

Cover Nut

Jam Nut

Feed Shaft Spring

Tension

Figure 26. Typical spring cover lock slot and

locking lug.

Spring-Cover

Lock Slot

Locking Lug

Figure 25. Fully seating quill shaft.

Depth Stop

Reads “0”

Rotate Oscillator

Pulley Until

Depth Stop

Reads Zero.