Roubleshooting – Stewart Filmscreen Corp LCD Front Projector User Manual

Page 19

Refer to the following guidelines if you encounter a difficulty in the operation

of your Stewart Filmscreen. Problems related to electrical or motor function

may require a qualified service person or electrician.

Should you have a problem that is not addressed here, call the Stewart

Filmscreen Corporation.

ABT-EM Trapdoor ElectriMask Electriscreen: Owner’s Manual

17

T

ROUBLESHOOTING

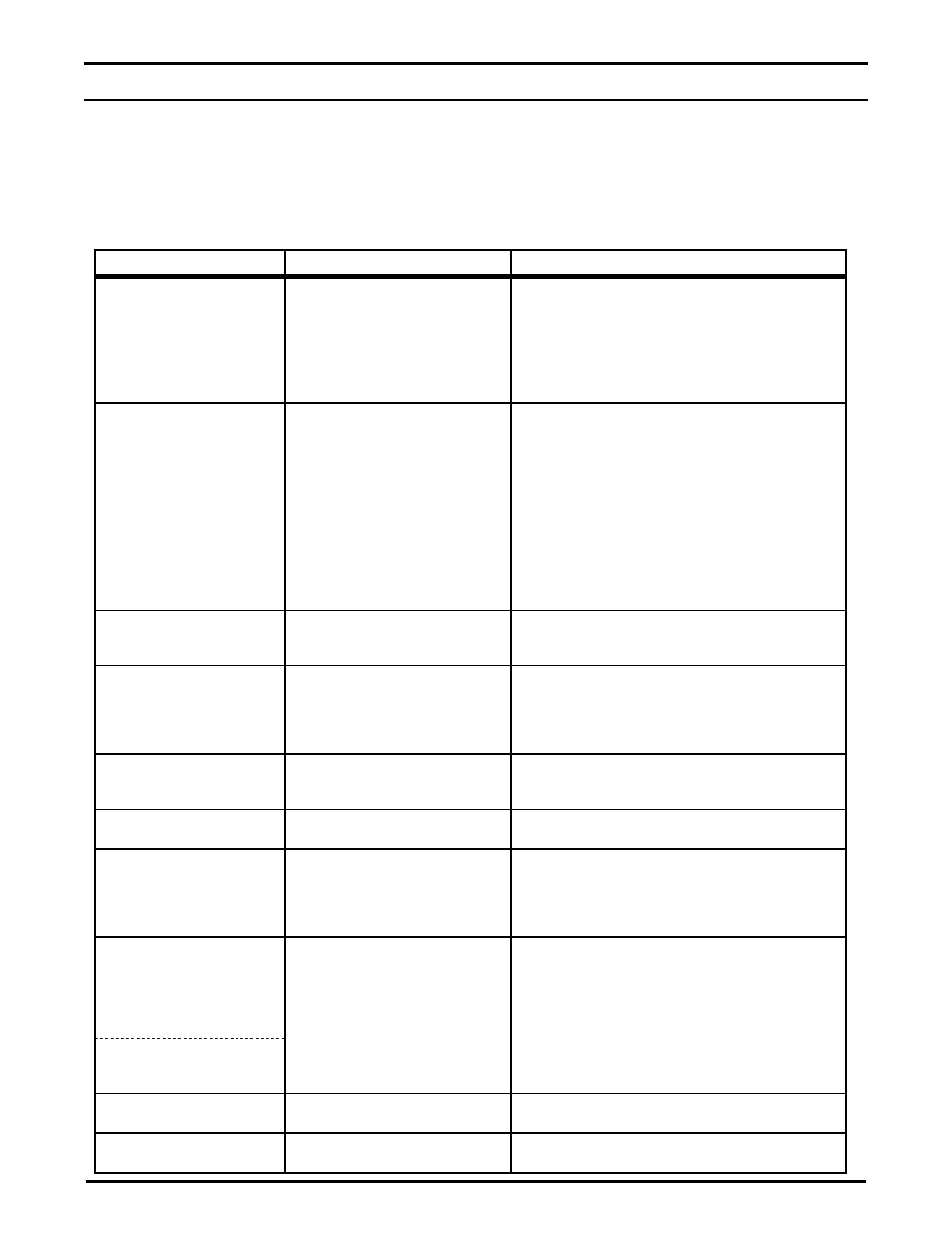

Problem description

Probable cause

Action to take

Door won't open.

Screen won't operate.

No AC power available.

Outboard switching problem.

Check to see if the circuit breaker has switched off.

Reset if needed.

Check outboard switching apparatus.

Check voltage availability. Contact an electrician.

Check that the toggle switches are in the correct

position. See Figure 3, p. 5.

Screen or mask won't roll up

or down (even though power

is available).

Bad connection at switch.

Polarity of STI line may be bad.

Have an electrician or qualified service person check

the connection as follows:

·

If you have a low voltage control unit, check switch-

line connections.

·

If you have a high voltage control switch, check

switch-line connections.

·

If you have a screen trigger interface, check line

connections, or the mini-plugs at the screen input or

projector output. Check 12V DC line for correct

polarity. Contacts may be sticking—tap relay to free

contacts.

Roller tube motors chatter

when power is activated.

Can be caused by voltage drop,

bad connections, or a defective

switch.

Have an electrician or qualified service person check

all hook-ups including all outboard wiring.

Unit hums in up mode.

(Screen or mask has already

retracted.)

The screen batten is retracting too

far into the case. Failure to

correct can damage motor and

screen. Do not use the unit until

this problem is resolved.

Have a qualified service person adjust the yellow UP

limit switch. Turn the adjusting screw clockwise.

Screen or mask drops when

up direction is activated

(grinding noise occurs).

Drop in voltage.

Motors require full voltage. Have an electrician or

qualified service person check available voltage.

Screen or mask continues

past bottom stop position.

White limit switch is out of

adjustment.

Readjust the white DOWN limit switch. See pp. 14-15

of this manual.

Battens retract too far into

case.

Yellow limit switch out of

adjustment. Failure to correct

can damage motor and screen.

Do not use the unit until this

problem is resolved.

Have a qualified service person readjust the yellow

UP limit switch. See pp. 14-15 of this manual.

Motor shuts off. Motor has

been in use for more than

2 minutes.

Motor is designed for short

operations (lowering and

retracting), not continuous duty.

Longer operation, such as during

setup and positioning, causes the

motor to overheat and shut off.

Allow the motor to cool down. Complete cooling can

take an hour or more. Heat gain is cumulative and

takes time to dissipate. If motor use is initiated before

it has cooled completely, the motor will shut down

again when it reaches maximum temperature.

Any controller (e.g., STI,

LVC, etc.) fails to operate

motor.

Dirt, finger prints, marks, etc.

on screen surface.

Improper handling of screen.

Brush off or use a mild detergent solution with clean

rag or cotton swab.

Indentations appear on

screen surface.

Debris or particles adhering to

screen due to static cling.

Check back of screen; gently brush debris away by

hand.