Johnson Controls TG9S*MP User Manual

Page 17

364861-UIM-B-0708

Johnson Controls Unitary Products

17

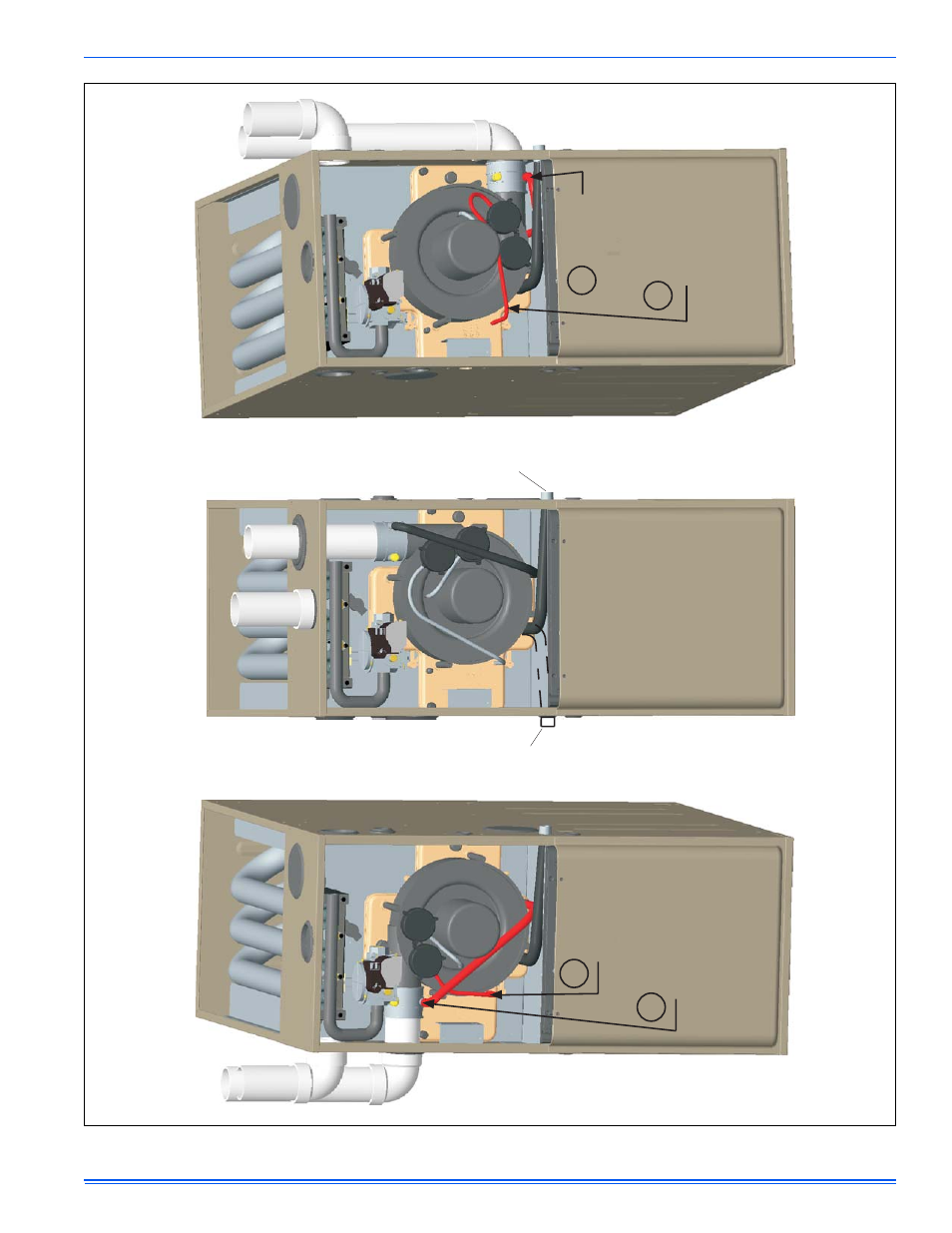

FIGURE 23: Upflow Configuration

INDUCER

ROT

A

TED

FOR

LEFT

SIDE

VENTING

(As

required

for

130K

model)

UPFLOW

AS

RECEIVED

(Except

for

130K

Model)

INDUCER

ROT

A

TED

FOR

RIGHT

SIDE

VENTING

When

drain

hose

routing

changes

are

required,

be

sure

to

cap

all

un-used

openings.

If

rerouting

hoses

-

excess

length

should

be

cut

of

f

so

that

no

sagging

loop

s

will

collect

and

hold

condensate,

which

will

cause

the

furnace

to

not

operate.

Shorten

pressure

switch

hose

Re-route

and

shorten

pressure

switch

hose

Shorten

rain

gutter

hose

Move

rain

gutter

hose

to

this

position

For100,

120&

130Kinput

furnaces,the

condensate

drainis

plumbedtoward

thelef

tcasing

outletfrom

thefactory

.

For 040, 060 & 080K input furnaces, the condensate

drain is plumbed toward the right casing outlet from the factory.

Condensate

drain

may

exit

cabinet

on

either

side.

1

2

1

2

130

K

Model

does

not

have

provisions

for

top

venting,

it

must

be

vented

through

a

side

opening.