Jet Tools JDS-12B User Manual

Page 10

10

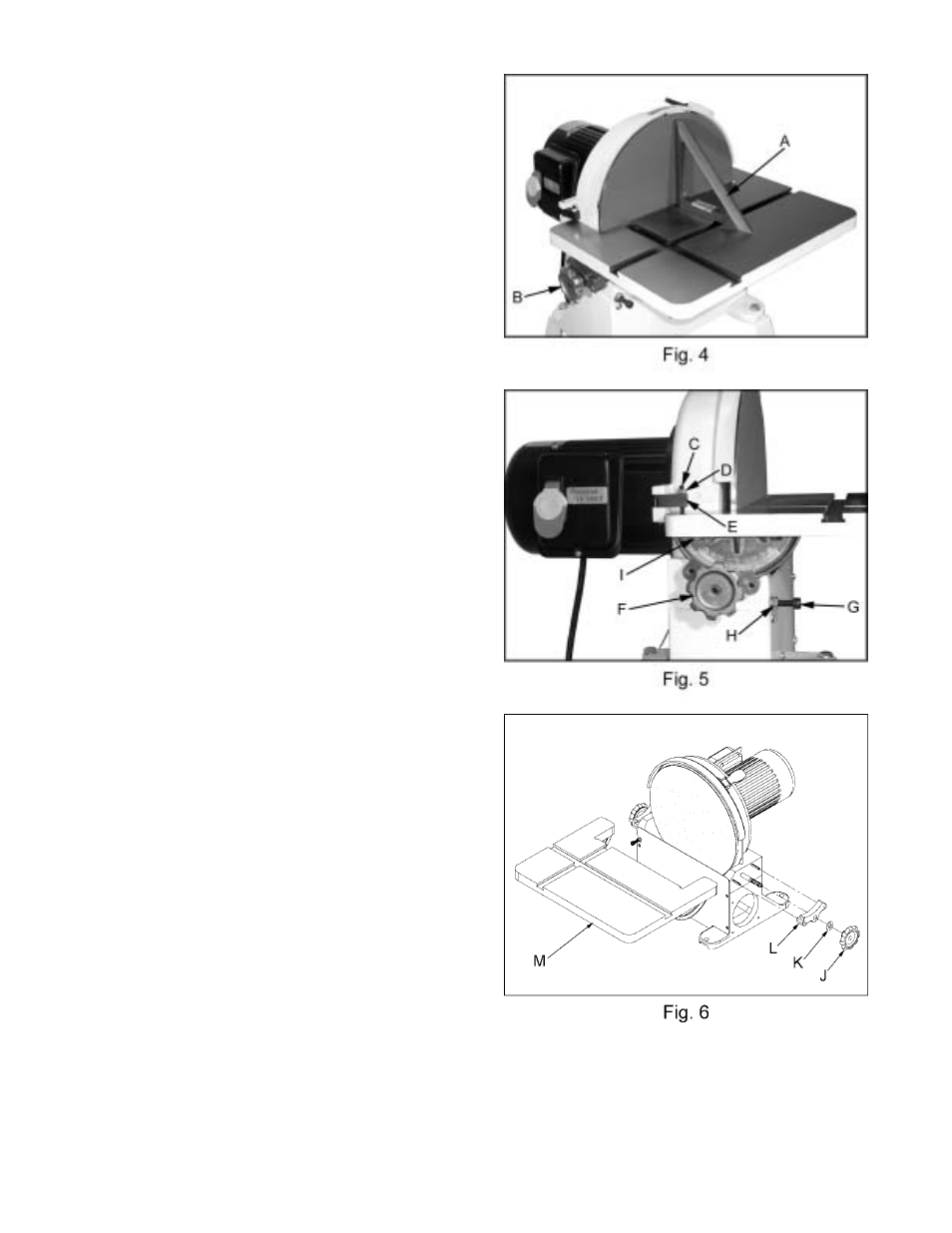

Table Adjustment

The table stops have been set-up at the factory.

However, if you run into a problem, or want to

check the table follow the below listed steps.

1. Loosen lock knobs (B, Fig. 4) and move the

table to the 90 degree position. Tighten

knobs and place a square (A, Fig. 4) against

the table and disc. The square should rest

flat against the table and disc.

2. If adjustment is needed move the table so

that it rests 90 degrees from the table, and

loosen the hex nut (D, Fig. 5) and tighten

the set screw (C, Fig. 5) until it contacts the

table surface. Tighten hex nuts. This will

properly adjust the 90-degree stop.

3. Loosen the lock knobs (F, Fig. 5) and tilt the

table up just enough to pivot the stop (E, Fig.

5) out of the way.

4. Tilt the table down until it hits the 45 degree

stop (G, Fig. 5). Tighten lock knobs, and

check the table with a combination square.

5. If adjustment is needed, loosen the hex nut

(H, Fig. 5) and adjust the socket head cap

screw (G, Fig. 5) until it contacts the table.

Tighten hex nuts.

6. Always maintain a gap of approximately

1/16” between the table edge, and disc. If

adjustment is necessary loosen hex cap

bolts (I, Fig. 5) and move the table into

position. Tighten hex cap bolts.

7. The table tilts between 15° up - 45° down by

loosening the lock knobs and tilting the table

to the desired angle. Tighten the knobs.

8. If you want to tilt the table up you need to

pivot the stop (E, Fig. 5) out of the way.

Sanding Disc Replacement

1. Disconnect machine from the power

source.

2. Remove the knobs (J, Fig. 6), washers (K,

Fig. 6), and trunnion holders (L, Fig. 6)

followed by the table assembly (M, Fig. 6).

3. Remove old sanding disc by striping from

wheel. Use a cleaner and putty knife to

remove the residue. Make sure the disc

plate is clean and dry.

4. Press the new disc firmly into place.