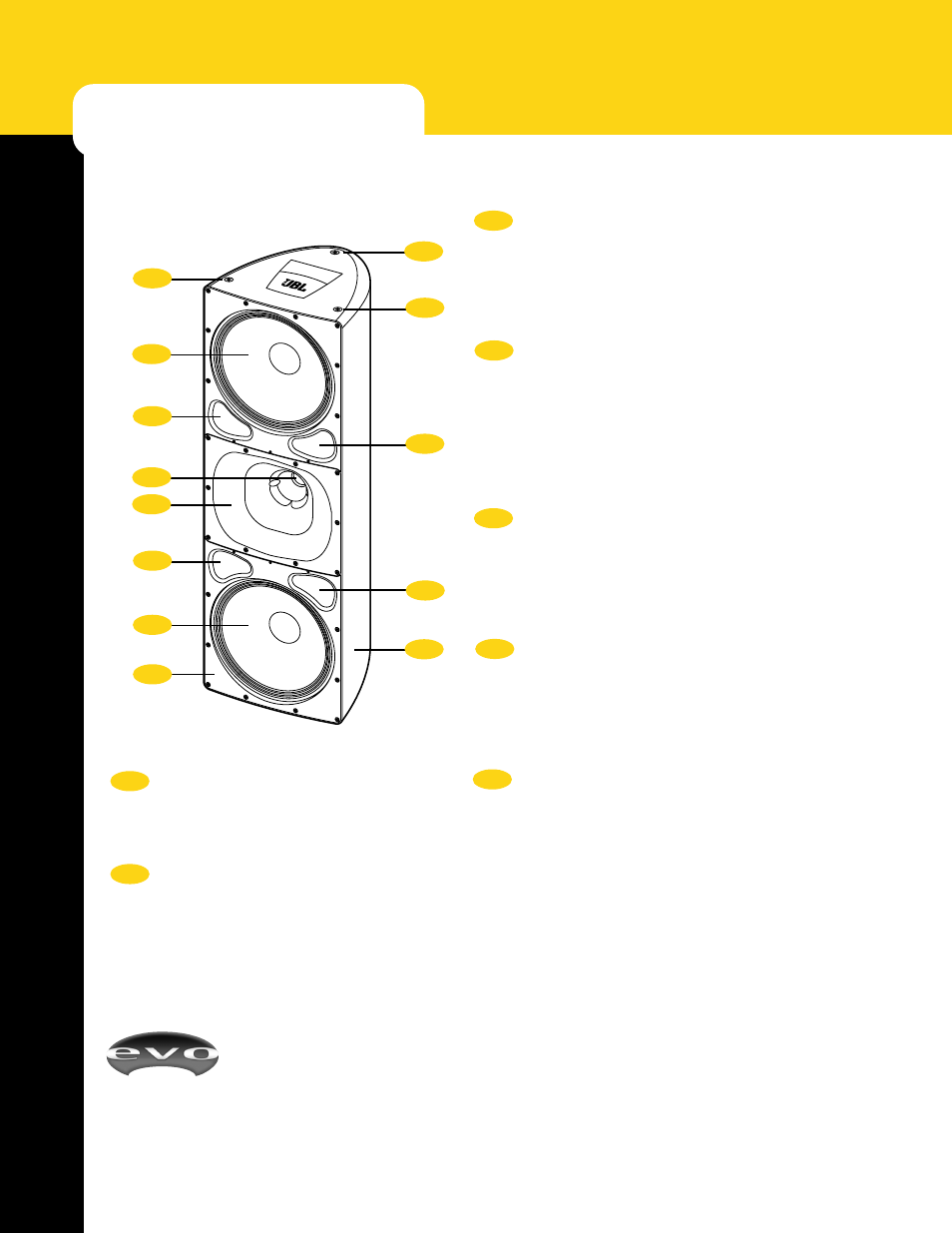

Evoi.324, Evoi.324 front/top – JBL EVO1.324 User Manual

Page 6

EVOi.324

4

F E A T U R E S

EVOi.324 FRONT/TOP

1

JBL Eyebolt System

Located on the top (and bottom) is our standard JBL eyebolt

system to accommodate ceiling attachment (and floor

mounting system, see Foot Kit, page 19), when required.

2

14” LF/MF Transducers

Each 14-inch, LF (Low Frequency) and LF/Mid carbon-

fiber cone transducer features our patented dual-coil, dual-

gap Neodymium Differential Drive (NDD™) technology

for 1/5

th

the weight of conventional ferrite transducers with

twice the power handling. Moreover, each transducer is

driven by its own 600 watt D-class (digital) amplifier.

1

1

1

2

2

3

3

3

3

4

5

6

7

Figure 1 - EVOi.324 Front & Top

(Grill removed for clarity)

3

Thermomaster

®

Vents

Each respective baffle vent, woofer motor, and basket are

all linked via the same thermal transfer path for maximum

heat dissipation. Taking heat away from the voice coil

effectively reduces power compression. The harder the

system works, the better it cools.

4

2430 Compression Driver

The JBL 2430 neodymium large-format compression driver

has a 1.5-inch exit and 3-inch voice coil with 100 watt

power handling. The revolutionary neodymium motor

structure results in an extremely compact and lightweight

HF (High Frequency) transducer, weighing only 2.5 lbs.

The JBL 2430 driver is powered by an internal 100 watt

linear amplifier.

5

Aluminum Waveguide

The aluminum waveguide effectively couples the JBL 2430

driver to the outside world. It works with the LF/MF and

LF transducers and our Filtered Array Technology (FAT™)

to achieve a constant 80

°

x 80

°

horizontal and vertical

coverage pattern.

6

Integrated Baffle

Our integrated transducer baffle and inertia grounding

straps are designed to lock all the components together,

maximizing acoustic output. The entire baffle area acts as

an open thermal window through which heat is allowed to

escape.

7

SMC Enclosure

The rear enclosure, fabricated from SMC (Sheet Molding

Compound), is in the form of a 2

nd

-order geometric design

for inherent strength, acoustic architecture, and transparent

aesthetics.

SMC Grille (not shown)

It looks like cloth, but it’s actually an anti-resonant, SMC-

reinforced, expanded steel grill, with an enhanced high

frequency spreading effect.