Capacities, Changing modes – Jet Tools JJP-12 User Manual

Page 2

Capacities

To make the JET JJP-12 Jointer-Planer as capable as it is versatile, the jointing and

planing width capacity is a full 12”. That capacity allows you to work with wider boards

without having to rip them down to fit common jointer

widths in the 6 to 8” range. Because both the jointer and

planer width capacities are the same, you can move

between those modes without having to add an additional

ripping step to the process.

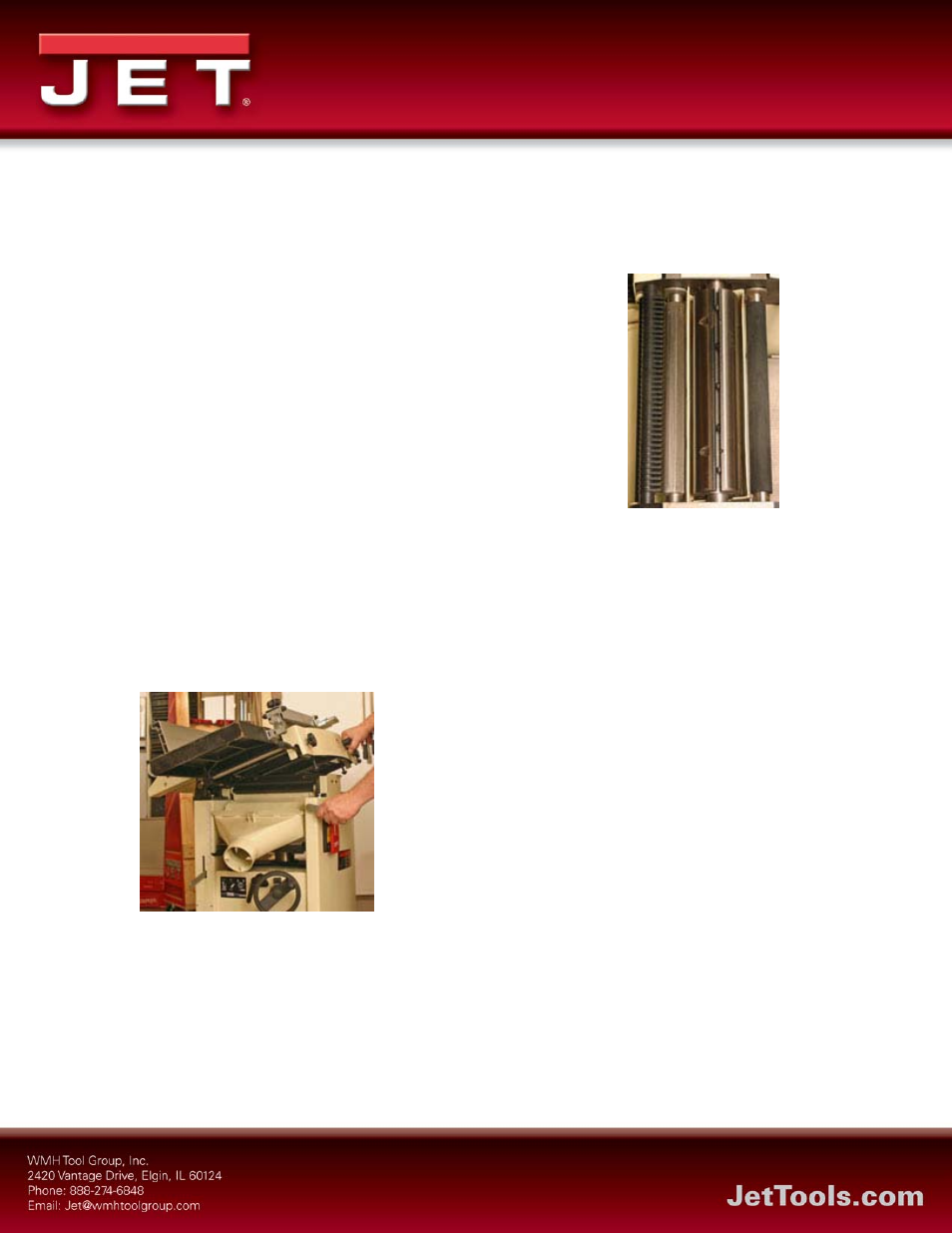

The precision machined 3-knife cutter

head and feed roller system (planing

mode) make the JET JJP-12 effective.

3-Knife Cutterhead

The JET JJP-12 Jointer-Planer uses a large 2 ¾”-diameter

cutterhead fitted with three high quality knives for both

jointing and planing operations. The cutterhead turns at

5500 RPM for all operations. The knives are retained

with conventional wedge bars and have jacking screws

that make setting their height precisely much easier.

Because this cutterhead is used for both jointing and

planing, setting the knives one time is all that is required.

Changing Modes

From the beginning, along with accuracy, capacity and

durability, developing a fast, easy way to change

between jointing and planing modes was high on the

design criteria list. The JET JJP-12 Jointer-Planer

sports a very simple, tool-free hinge based system that

allows changing between jointing and planing modes

very quickly without having to remove any

components.

Changing from jointing to planing or

back on the JET JJP-12 is fast and

simple. Unlock the jointing deck, lift it to

its upright position, flip the dust collector

into planing position and engage the feed

rollers. It takes less time to do than to

describe! Going back to jointing is just as

fast.

A pair of locking levers on the cabinet sides release the

jointing bed which is then rotated up to expose the

planer section. Lifting the cast iron jointer bed

assembly (moves as one piece) is made easier because

of spring-assisted hinges that reduce that effort

substantially. A drop in lock at the hinge point secures

the jointer bed in the upright position.