Tension roller alignment, Tension roller pressure adjustment – Jet Tools Drum Sander User Manual

Page 18

18

NOTE: Keep track of how many revolutions of

the fine tune knob are needed to change drum

alignment for wider (over 22”) sanding. When

sanding narrow stock (less than 22”) loosen the

four screws (Figure 22) and turn fine tune

adjustment knob counterclockwise the same

amount as the initial wide sanding so that drum

is again parallel.

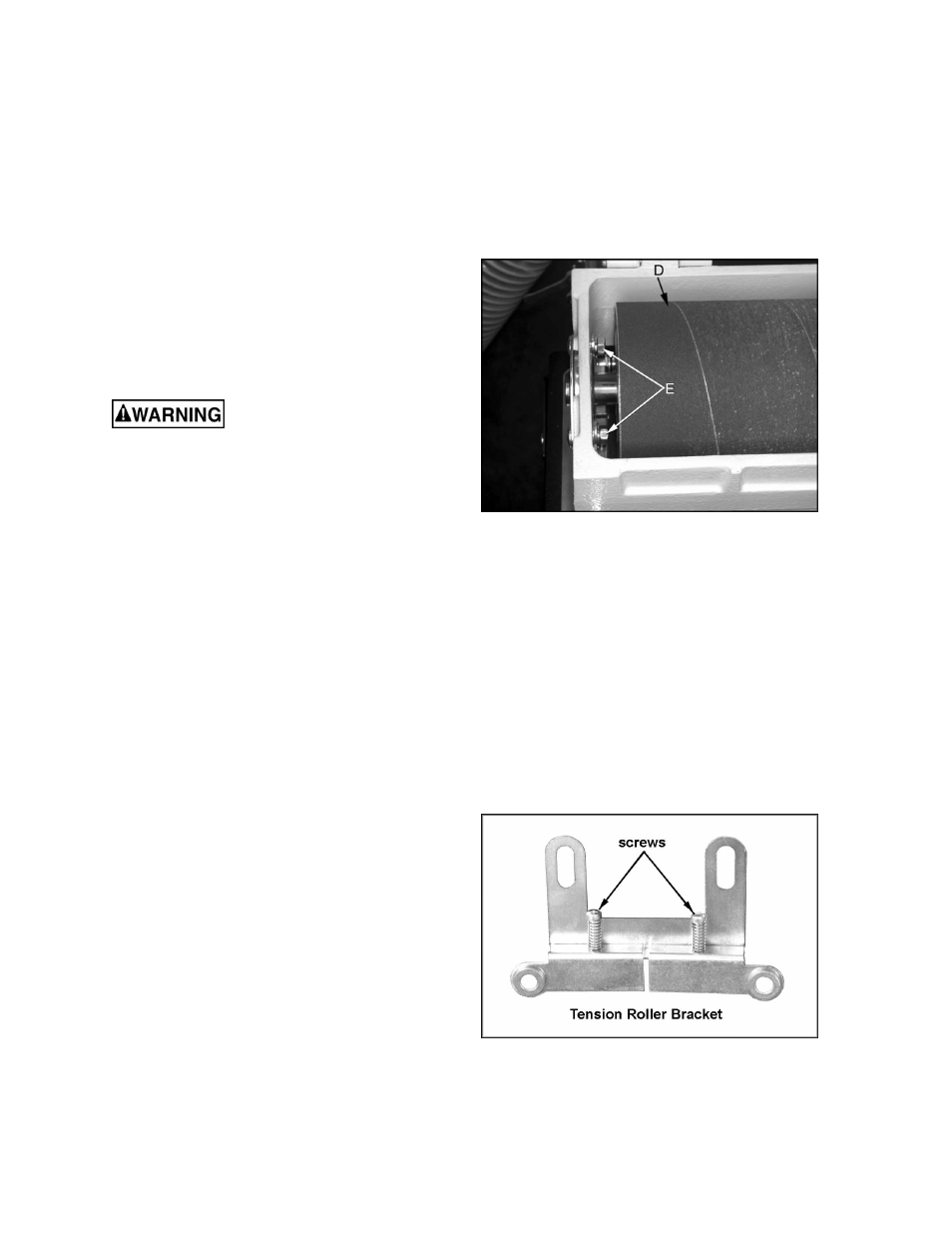

Tension Roller Alignment

The infeed and outfeed rollers are tensioned to

provide downward pressure on the workpiece to

prevent slippage on the feed conveyor. Tension

rollers are set at the factory, but should be

inspected and may require adjustment as the

sander receives use.

Improperly adjusted tension

rollers (i.e. those set too high, rendering

them non-functional) could allow kick-back

of pieces being sanded.

1. Unplug sander from power source and

remove abrasive (D, Figure 24) from drum.

2. Loosen all four hex nuts on the bearing bolts

(E, Figure 24). This will allow both tension

rollers to drop to their lowest position.

(NOTE: Figure 24 only shows outboard end

of drum. Adjustments must be made on both

ends of drum.)

3. Lower sanding drum to where it just

contacts the conveyor bed. Then raise the

sanding drum by making 3/4 turn of the

height adjustment handle.

4. Tighten the four hex nuts (E, Figure 24).

Both tension rollers are now positioned

about 1/16” below the bottom of the sanding

drum.

Tension Roller Pressure Adjustment

You can increase or decrease tension roller

pressure by turning the screws on the tension

roller brackets (Figure 25).

Too much tension roller pressure can result in a

“snipe” mark, which is identified as a visible line

running across the width of the board and

located approximately 2-1/4” from the end of the

board.

If the snipe occurs on the leading end of the

board, adjust the outfeed tension roller. If the

snipe occurs on the trailing end of the board,

adjust the infeed tension roller.

Tension roller pressure can also be adjusted by

raising the height of the rollers, as follows:

Figure 24

Figure 25