Service and adjustments, Warning – Jonsered CS 2138 User Manual

Page 12

12

SERVICE AND ADJUSTMENTS

WARNING

: Disconnect the spark

plug before performing maintenance, except

for carburetor adjustments.

We recommend all service and adjustments

not listed in this manual be performed by an

Authorized Service Dealer.

MAINTENANCE SCHEDULE

Check:

Fuel mixture level

Before each use

. . . .

Bar lubrication

Before each use

. . . . . . .

Chain tension

Before each use

. . . . . . .

Chain sharpness

Before each use

. . . .

For damaged parts

Before each use

. .

For loose caps

Before each use

. . . . . .

For loose fasteners

Before each use

. . .

For loose parts

Before each use

. . . . . .

Inspect and Clean:

Bar

Before each use

. . . . . . . . . . . . . . . .

Complete saw

After each use

. . . . . . .

Air filter

Every 5 hours*

. . . . . . . . . . . . .

Chain brake

Every 5 hours*

. . . . . . . .

Spark arresting screen

and muffler

Every 25 hours*

. . . . . . . . .

Replace spark plug Yearly

.

Replace fuel filter

Yearly

. . .

* Hours of Operation

AIR FILTER

CAUTION

: Do not clean filter in gaso-

line or other flammable solvent to avoid

creating a fire hazard or producing harmful

evaporative emissions.

Cleaning the air filter:

A dirty air filter decreases engine perform-

ance and increases fuel consumption and

harmful emissions. Always clean after every

5 hours of operation.

1. Clean the cover and the area around it to

keep dirt and sawdust from falling into

the carburetor chamber when the cover

is removed.

2. Remove the parts as illustrated below.

3. Wash the filter in soap and water. Rinse

in clean cool water. Air dry completely

before reinstalling.

4. Add a few drops of oil to the filter;

squeeze filter to distribute oil.

5. Reinstall parts.

Air Filter

Cylinder

Cover

Screws

Cylinder

Cover

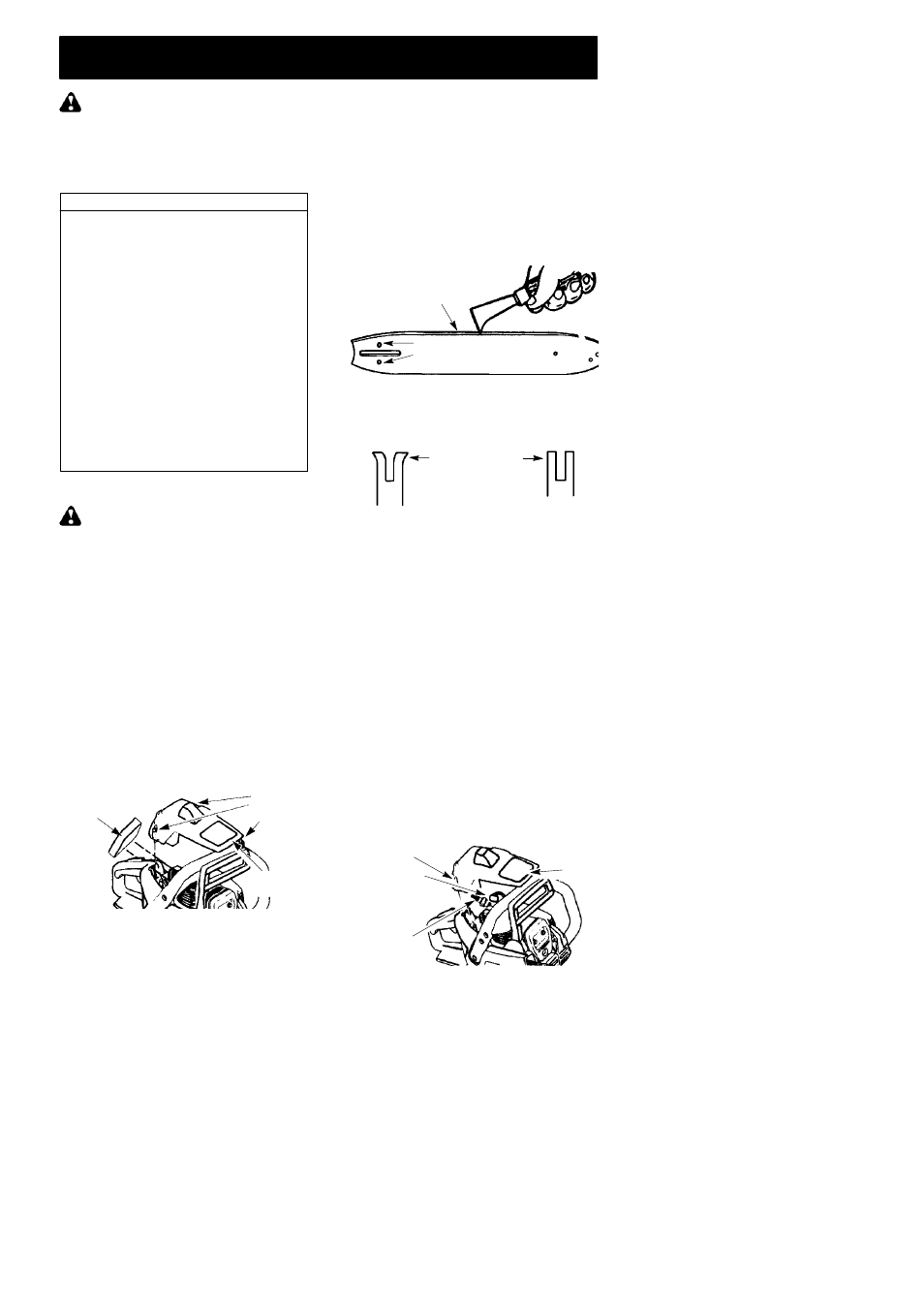

BAR MAINTENANCE

If your saw cuts to one side, has to be forced

through the cut, or been run with an improper

amount of bar lubrication it may be neces-

sary to service your bar. A worn bar will dam-

age your chain and make cutting difficult.

After each use, ensure ON/STOP switch is

in the STOP position, then clean all sawdust

from the guide bar and sprocket hole.

To maintain guide bar:

S

Move ON/STOP switch to the STOP posi-

tion.

S

Loosen and remove chain brake nuts and

chain brake. Remove bar and chain from

saw.

S

Clean the oil holes and bar groove after each

5 hours of operation.

Remove Sawdust From

Guide Bar Groove

Oil Holes

S

Burring of guide bar rails is a normal

process of rail wear. Remove these burrs

with a flat file.

S

When rail top is uneven, use a flat file to re-

store square edges and sides.

Correct Groove

Worn Groove

File Rail Edges

and Sides

Square

Replace guide bar when the groove is worn,

the guide bar is bent or cracked, or when

excess heating or burring of the rails occurs.

If replacement is necessary, use only the guide

bar specified for your saw in the repair parts list

or on the decal located on the chain saw.

SPARK PLUG

The spark plug should be replaced each

year to ensure the engine starts easier and

runs better. Ignition timing is fixed and non-

adjustable.

1. Loosen 3 screws on cylinder cover.

2. Remove the cylinder cover.

3. Pull off the spark plug boot.

4. Remove spark plug from cylinder and

discard.

5. Replace with Champion RCJ--7Y spark

plug and tighten securely with a 19 mm

socket wrench. Spark plug gap should

be 0,5 mm.

6. Reinstall the spark plug boot.

7. Reinstall the cylinder cover and 3

screws. Tighten securely.

Screws

Spark

Plug Boot

Spark

Plug

Cylinder

Cover