Safety instructions – Jonsered 670 User Manual

Page 12

12

– English

SAFETY INSTRUCTIONS

!

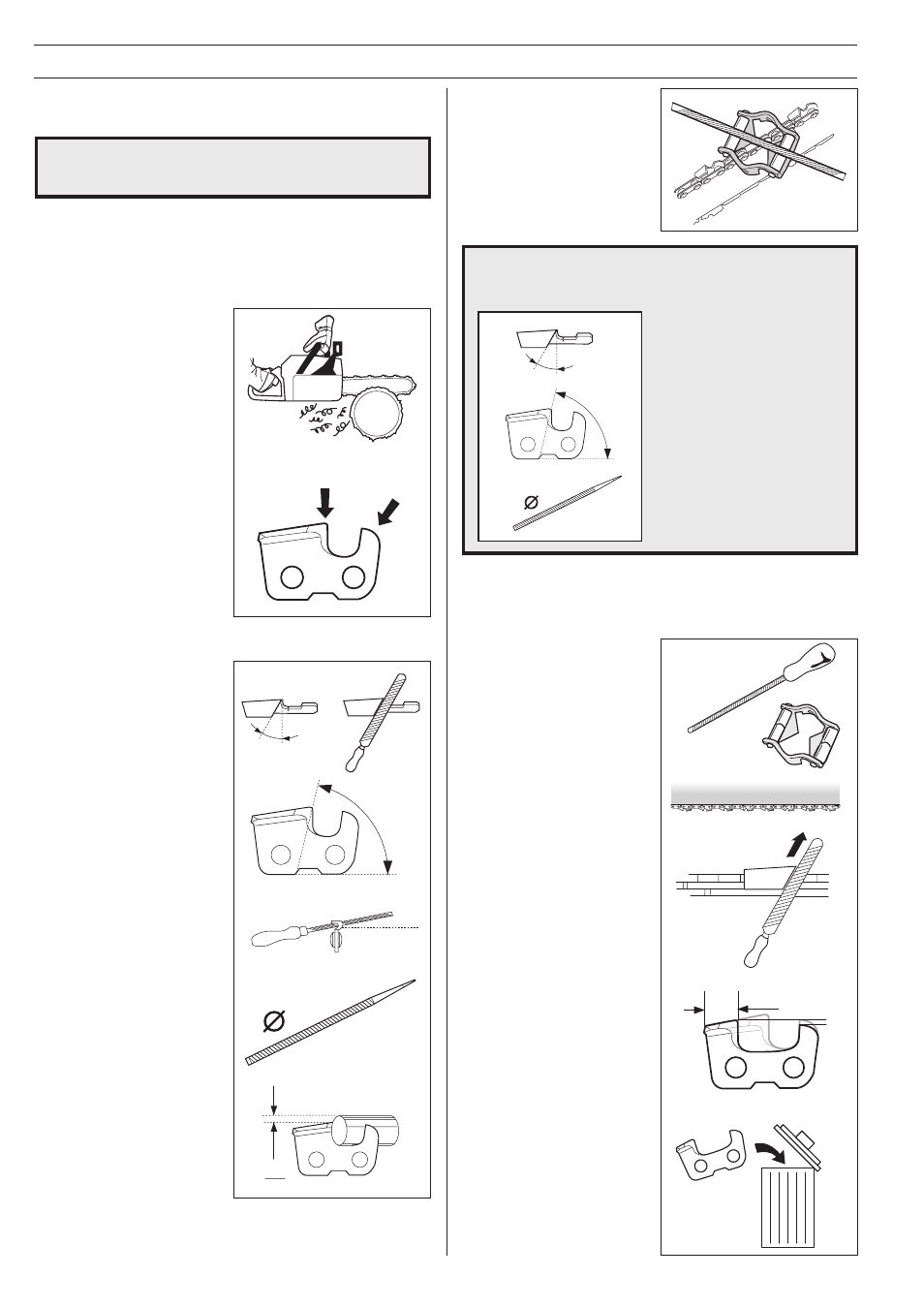

2 Sharpening your chain and adjusting

raker clearance

The risk of kickback is increased with a badly

sharpened chain!

A

General information on sharpening cutting teeth

• Never use a blunt chain. When the chain is blunt you have to

exert more pressure to force the bar through the wood and

the cuttings will be very small. If the chain is very blunt it will

not produce any cuttings at all, just wood powder.

• A sharp chain eats its way

through the wood and

produces long, thick

cuttings.

• The cutting part of the chain

is called the CUTTING LINK

and this consists of a

CUTTING TOOTH (A) and

the RAKER LIP (B). The

cutting depth is determined

by the difference in height

between the two.

• When you sharpen a cutting tooth there are five important

factors to remember.

FILING ANGLE

CUTTING ANGLE

FILE POSITION

ROUND FILE DIAMETER

FILE DEPTH

See the

”Technical data” section for information about

sharpening your saw chain.

!

It is very difficult to sharpen a

chain correctly without the

right equipment. We

recommend you use a file

gauge. This will help you

obtain the maximum kickback

reduction and cutting

performance from your chain.

The following faults will increase the risk of

kickback considerably.

•

FILE ANGLE TOO

LARGE

•

CUTTING ANGLE

TOO SMALL

•

FILE DIAMETER

TOO SMALL

B

Sharpening cutting

teeth

To sharpen cutting teeth you

will need a ROUND FILE and

a FILE GAUGE. See the

”Technical data” section for

information on the size of file

and gauge that are

recommended for your saw

chain.

1

Check that the chain is

correctly tensioned. A

slack chain is difficult to

sharpen correctly.

2

Always file cutting teeth

from the inside face,

reducing the pressure on

the return stroke.

File all the teeth on one

side first, then turn the

saw over and file the

teeth on the other side.

3

File all the teeth to the

same length. When the

length of the cutting teeth

is reduced to 4 mm

(0,16") the chain is worn

out and should be

replaced.

B

A

1

5

min 4 mm

(0,16")