Operating instructions, Installation – Ingersoll-Rand 650556-1 User Manual

Page 2

PAGE 2 OF 4

650556-1

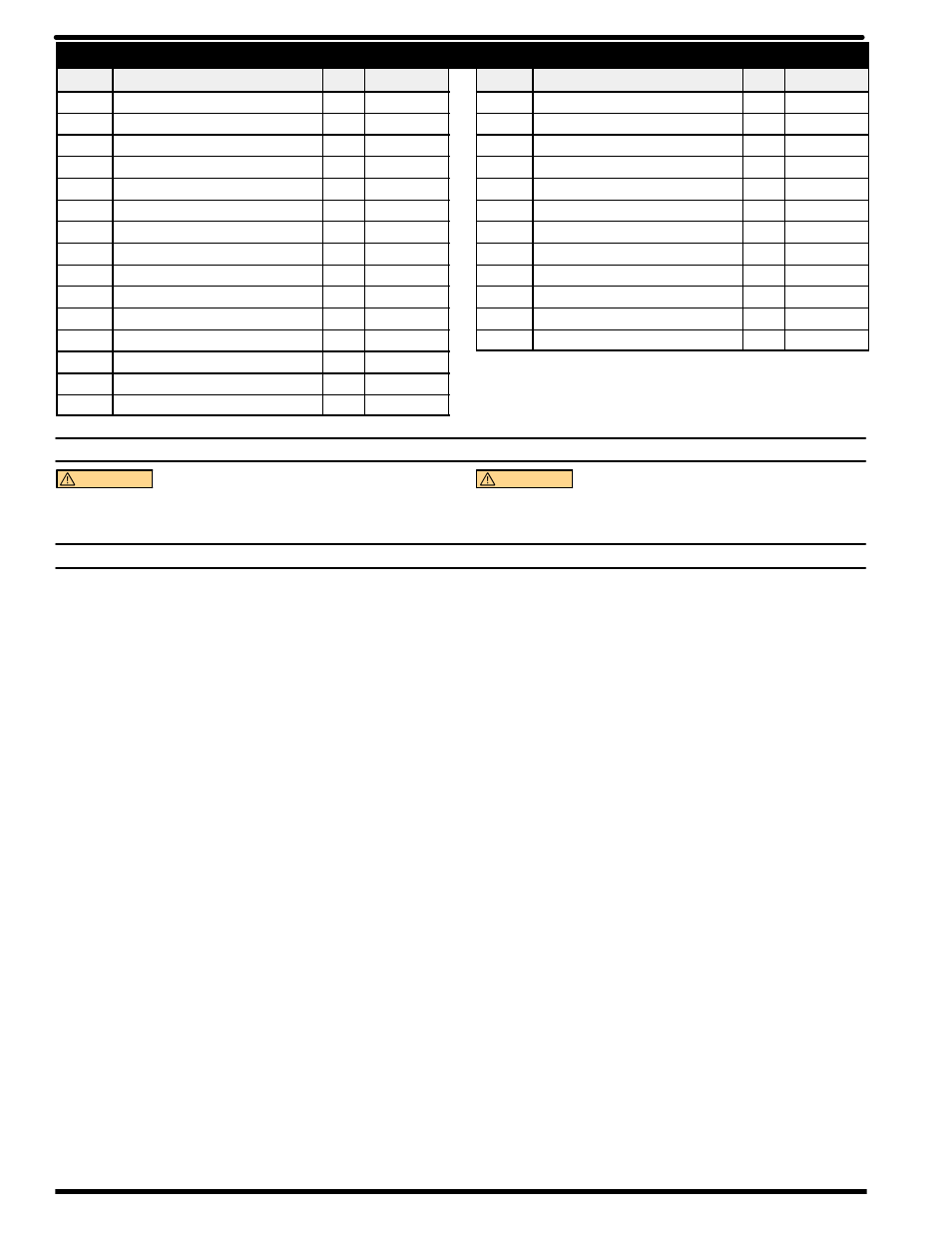

PARTS LIST / 650556-1

ITEM DESCRIPTION

(Size in Inches)

QTY

PART NO.

ITEM DESCRIPTION

(Size In Inches)

QTY

PART NO.

1 Two Ball Piston Pump

(1)

650685-P43

2 Cart Assembly

(Includes Items 6 thru 14)

(1)

67139

6 Washer

(3/8”)

(4)

Y13-6-C

7 Screw

(3/8” - 16 x 1-1/4”)

(4)

Y6-66-C

8 Nut

(3/8” - 16)

(4)

Y12-6-C

10 Brace

(1)

95102

11 Screw

(5/16” - 18 x 3/4”)

(4)

Y6-53-C

12 Nut

(5/16” - 18)

(4)

Y12-5-C

13 Washer

(5/16”)

(4)

Y14-516-C

14 Cart Welding Assembly

(1)

67138

15 Material Filter

(Includes Item 16)

(1)

651422-70

16 Plug

(3/8”)

(1)

Y17-13-S

17 Muffler

(1)

91790-ZZ

j 18 3/4” Suction Hose Assembly

(1)

622606-5

j 19 90_ Elbow

(3/4”)

(1)

Y43-15-S

j 20 Suction Tube (5 Gallon)

(1)

94263-1

21 Hose Assembly

(1)

628092-F

22 Gauge

(1)

104500

23 Piggyback Filter/Regulator

(1)

P39344-100

24 Nipple

(1/2” x 2” (m))

(1)

Y44-31-C

25 Bushing

(1/2” - 14 (m) x 1/4” - 18 (f))

(1)

94271

26 Nipple

(1/4” - 18 (m))

(2)

1950

27 Street Tee

(1/4” - 18)

(1)

94270

28 Needle Valve

(1)

94269

29 Adapter

(1” (m) x 1/2” (f))

(1)

94256

30 90

_ Adapter

(1” (m) x 1/4” (f) x 3/4” (f))

(1)

94254

31 Plug

(1)

Y17-11-S

j Parts included in 67140-1 Asm (std)

Available: 67140-2 Asm. uses 94263-2 (36” Inlet Tube)

OPERATING INSTRUCTIONS

WARNING DO NOT EXCEED MAXIMUM OPERATING PRES-

SURE OF 6000 P.S.I. (414 BAR) AT 100 P.S.I. (6.9 BAR) AIR IN-

LET PRESSURE.

WARNING REFER TO THE PUMP MANUAL FOR ADDITION-

AL OPERATING AND SAFETY PRECAUTIONS AND OTHER IM-

PORTANT INFORMATION.

INSTALLATION

OPERATING INSTRUCTIONS / INITIAL SETUP PROCEDURE

This unit comes assembled except for the air supply hose, gun and ma-

terial hose which must be attached.

x A connector, coupler and air supply hose and must be supplied to

the air regulator.

x Attach a Ground wire to a suitable ground and the Ground Lug

provided on the pump Air Motor.

x Keep containers covered to prevent contamination.

1. Turn the knob on the air regulator counter-clockwise to zero p.s.i.

2. Attach hose and gun. Place pump inlet tube into a full container of

material.

3. Start the pump to cycle by turning the air regulator knob clockwise.

The pump will cycle several strokes until pressure is built up in the

system, at which time it will stall, check for any loose fittings or leak-

age. Check all connections and re-tighten as necessary.

4. Relief Valve (28) is used to relieve pressure in the hose in order to

change spray tips. Open the relief valve to relieve pressure. Close

the relief valve to continue spray operation.