Miller Electric DB1825R User Manual

Page 8

OM-1603 Page 6

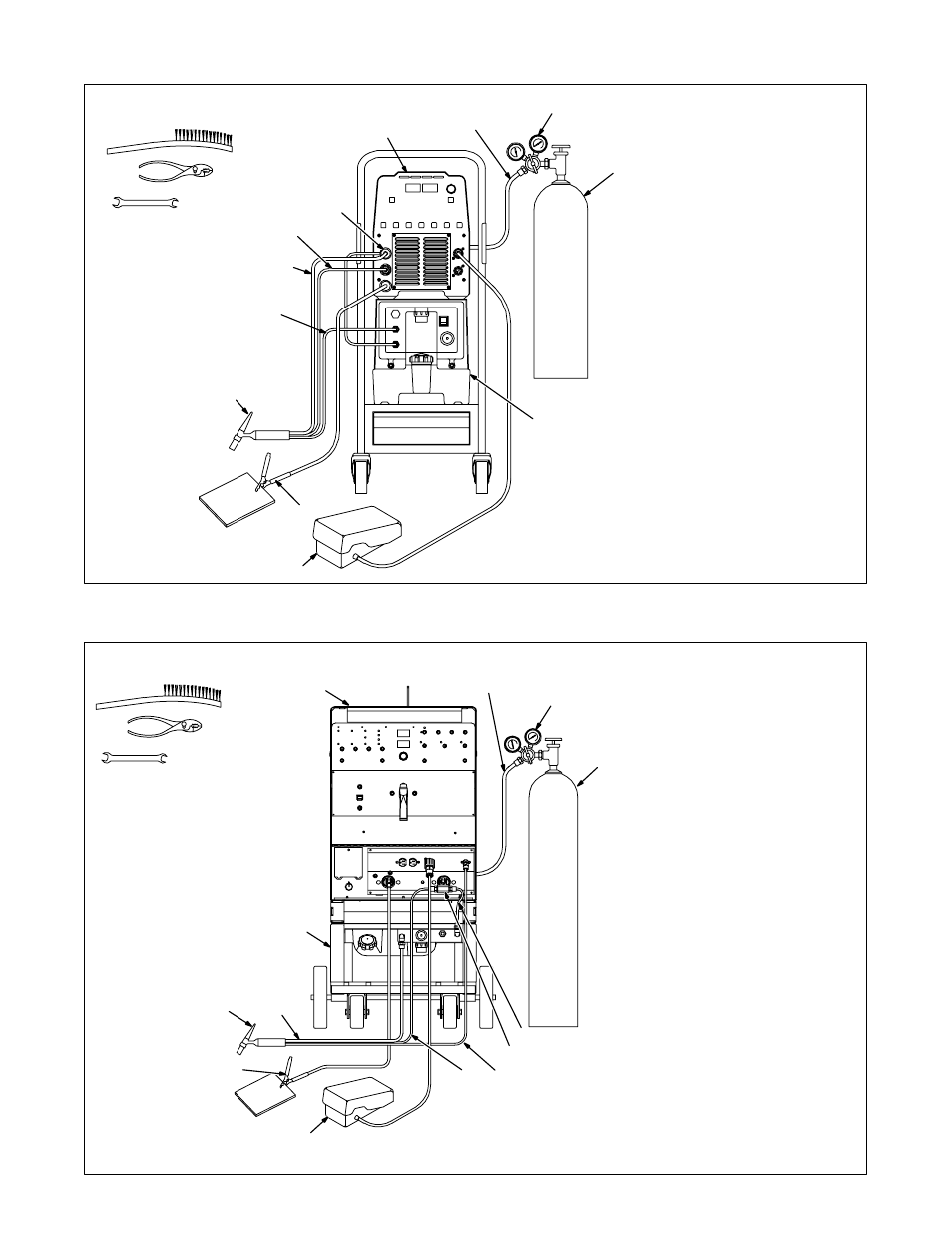

B. Connecting Torch To A Dynasty

t

300 DX Or Maxstar

R

300 DX TIGRunner

t

Unit

803 311

Tools Needed:

5/8, 7/8, 1-1/8 in

2

3

1

10

5

6

8

11

4

7

9

12

Y

Turn Off welding power source

power before installing torch.

1

Gas Hose With 5/8-18 Right-

Hand Fittings (Customer Sup-

plied)

Connections:

2

Regulator/Flowmeter

3

Gas Cylinder

4

Coolant System

5

Torch

6

Coolant-Into Torch Hose (Blue)

7

Torch Gas Hose

8

Coolant-Out Of Torch/Power

Cable (Red)

9

International Style Adapter

Connect coolant-out of torch/power

cable to power cable adapter, and con-

nect adapter to weld output terminal.

10 Work Clamp

Connect work clamp to a clean, paint-

free location on workpiece, close to

weld.

Use wire brush or sandpaper to clean

metal at weld joint area.

11 Welding Power Source

12 Foot Control

C. Connecting Torch To A Syncrowave

R

250 DX Or 350 LX TIGRunner

t

Unit

803 311

Tools Needed:

5/8, 7/8, 1-1/8 in

Y

Turn Off welding power source

power before installing torch.

1

Gas Hose With 5/8-18 Right-Hand

Fittings (Customer Supplied)

Connections:

2

Regulator/Flowmeter

3

Power Source

4

Gas Cylinder

5

Coolant System

6

Coolant Hose (Supplied With TI-

GRunner)

7

Power Cable Adapter

8

Torch

9

Coolant-Into Torch Hose (Blue)

10 Coolant-Out Of Torch/Power

Cable (Red)

Connect torch coolant-out of torch/pow-

er cable to power cable adapter, and

connect adapter to weld output terminal.

11 Torch Gas Hose

12 Work Clamp

Connect work clamp to a clean, paint-

free location on workpiece, close to

weld.

Use wire brush or sandpaper to clean

metal at weld joint area.

13 Foot Control

4

3

1

2

5

6

11

8

10

9

12

7

13