Wood sanding machines – Metabo Wood Sanding Machine User Manual

Page 3

152 |

WOOD SANDING MACHINES

CONSIDERED THE BEST, NOT ONLY ON THE SURFACE.

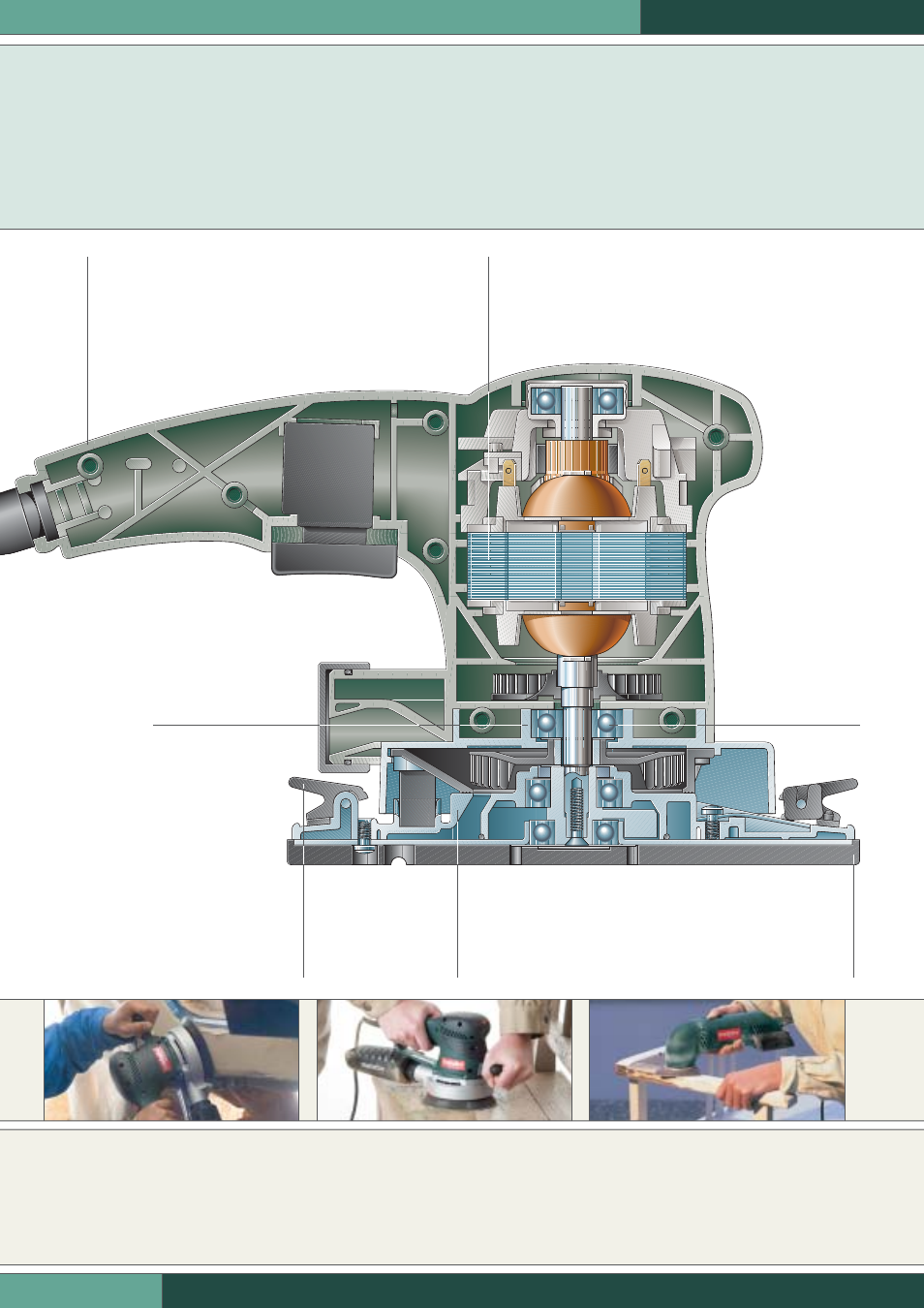

Metabo power control system

A built-in backing pad brake limits

scratches when placing the tool on the

material. This means that no manual post-

processing is needed. This makes the disc

sander particularly suitable for sanding very

thin materials and sensitive surfaces.

Unique Duo oscillating circuit setting

Two adjustment options provide 100% finer

surfaces with the small oscillating circuit

diameter and 70% more material removal

with the large one.

DSE 300 Intec – the first triangular base-plate

sander with integrated dust extraction unit

No obstructive suction hose; the dust is

collected in the integrated dust container.

Ergonomic design

Safe and comfortable

work as it fits perfectly

in the hand.

Electro-dynamic

balancing system

Fatigue-free work due to

especially low vibrations.

Sanding up to the outer-

most corner

Oscillating plate

without protruding parts.

Die-cast aluminium

oscillating plate

More robust material

provides longer service

life.

Solid aluminium die

cast bearing flange

Guarantees a longer

service life of the

machine.

Four quality ball

bearings protected

ideally against dust

Longer service life

due to ideal dust

protection.

Quick clamping system

For the fast and com-

fortable change of the

sanding sheet.

External dust extraction

or extraction by Intec

filter system possible

(accessory)

The Metabo range of sanders are considered amongst

the best in the industry. Copied by many and perfected

by none the Metabo sanding range gives you a choice

of machines built to the demands of the profes-

sional. Be it for fine finishing, detail finishing, high

stock removal or surface preparation Metabo has the

sander and accessory to perfect the job in hand time

and time again.