Constant dry heat, For the best drying environment, Desiccant rotor technology cuts drying time – Matsui America DMZ2 Series User Manual

Page 3

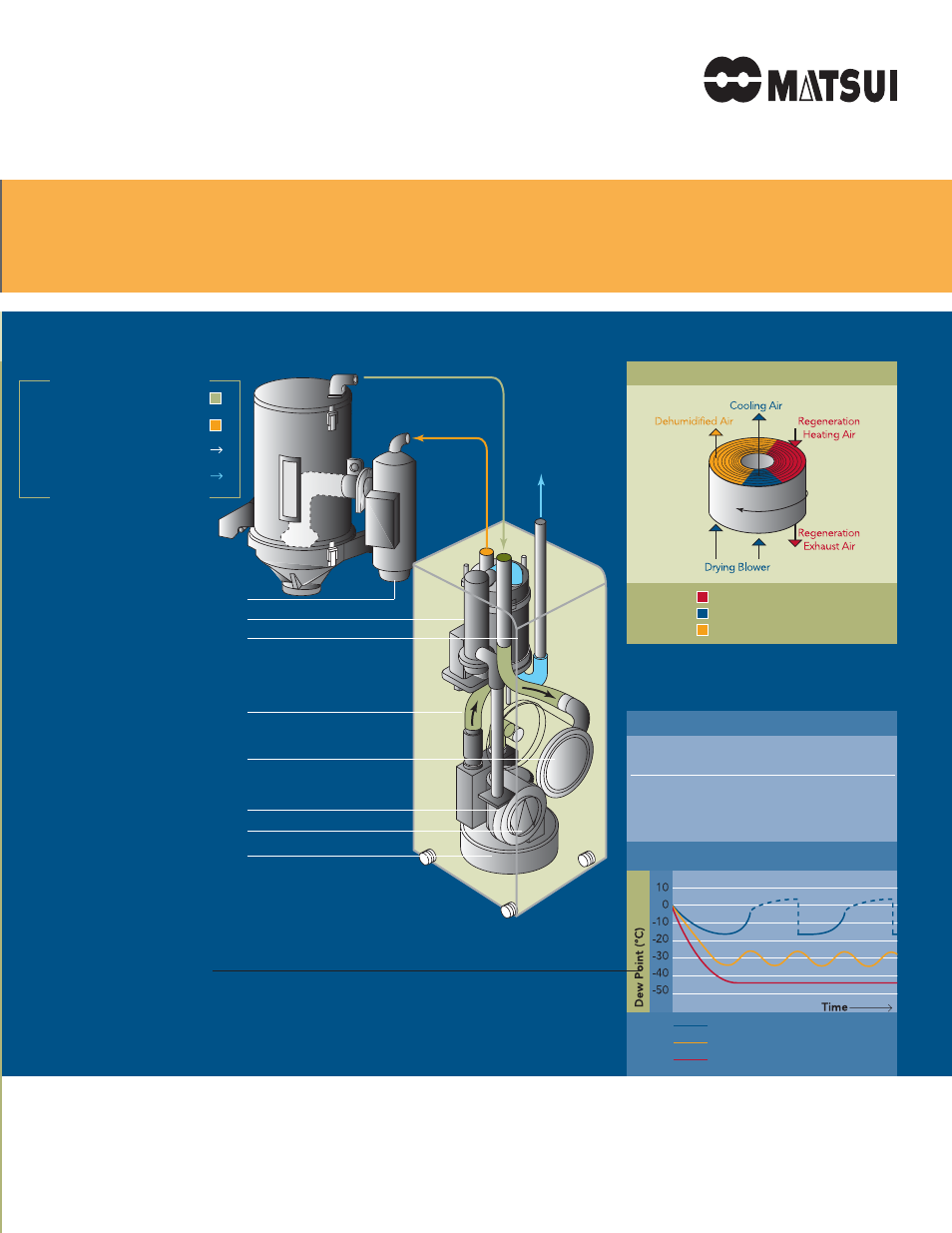

Matsui’s desiccant rotor technology has become the

industry standard in dehumidifying hot-air drying equipment.

Its unique, honeycomb design— molecular sieve desiccant, bond-

ed and then baked onto ceramic paper — eliminates powder that

can contaminate the system. Its large contact area effectively

absorbs at high temperatures, drying resin in half the time while

stabilizing dew points at a constant – 40˚F.

Resin

Other

Desiccant

Dryers

Dryers

Polycarbonate

3–4 hours

1.5 hours

Nylon

4–6 hours

2.5 hours

PET

6–8 hours

3.0 hours

Single Tower Type Dehumidifier

Multi-Tower Type Dehumidifier

Desiccant Rotor System

the dmz2 dries resin faster.

and it stabilizes dew points.

Desiccant rotor technology cuts drying time

Regeneration Heating Zone

Cooling Zone

Dehumidifying Zone

the stream of air inside the rotor

Compare Matsui to the competition:

Return Air

Dehumidified Air

Rotor Removes Moisture

Moisture Removed from Rotor

Constant dry heat

for the best drying environment.

now in a compact portable design.

Return Air

Dehumidified Air

Regeneration

Exhaust

Regeneration Air Filter

Regeneration Blower

Regeneration Heater

Desiccant Absorption Rotor

To Desiccant Rotor

Drying Heater

Drying Blower

Aftercooler