Warning, 7. maintenance – Miller Electric 3000-4AH User Manual

Page 14

OM-659 Page 8

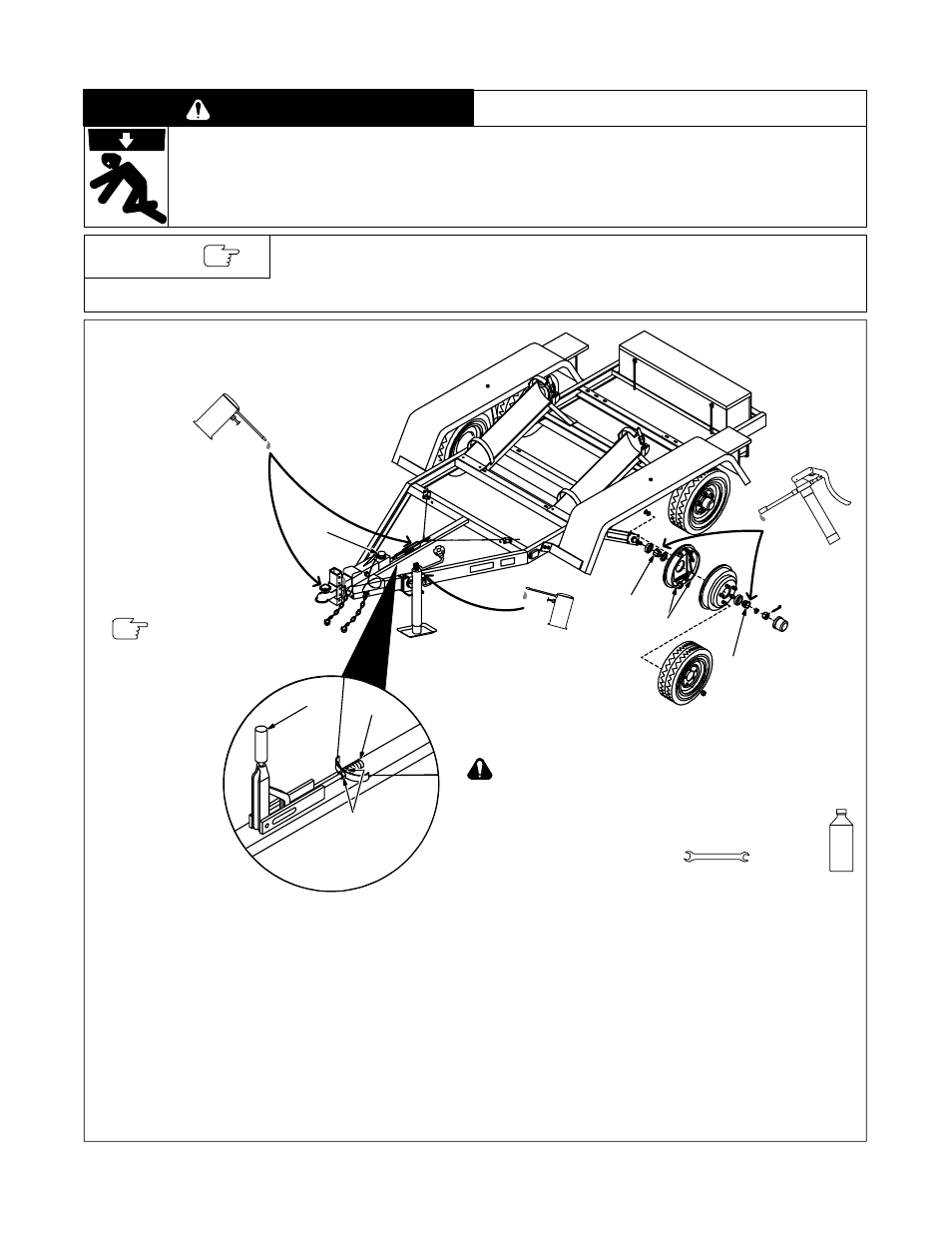

3-7.

Maintenance

WARNING

FALLING EQUIPMENT can cause serious personal injury and equipment damage.

•

Apply parking brake while performing maintenance (see Section 3-1).

•

Support trailer with jack, or use proper equipment to lift trailer.

•

Do not put any body part under trailer while lifting or performing maintenance.

rwarn1.1* 3/93

Do not use trailer if any part is damaged or not working properly. When performing

maintenance, check trailer for worn, damaged, or non-working parts. Check for

free rotation of assemblies mounted on bushings or bearings.

NOTE

ST-800 017

Support trailer with jack. Apply parking brake.

Once a year, lubricate all moving parts on

trailer with SAE 20W oil. Lubricate more often

if trailer is exposed to elements or subject to

frequent off-road use.

1

Wheel Bearings

Every 12,000 miles, check wheel bearings.

Repack bearings if necessary using a good

quality lithium-based extreme pressure

grease.

2

Brake Linings

Check linings every 20,000 miles and re-

place if necessary.

When reinstalling wheels, be sure wheel nuts

are properly tightened (see Trailer Towing

Safety Precautions).

3

Brake Fluid Reservoir

Check fluid level in reservoir at least 3 times

yearly. Add fluid if not up to full mark. Use

DOT Series 3 brake fluid from a sealed con-

tainer. See brake actuator Owner’s Manual.

4

Parking Brake Handle

To adjust parking brake, release brake and

turn handle. Turn clockwise to increase

brake pressure or counterclockwise to de-

crease brake pressure.

Adjust brake so less than 30 ft lb (41 N

.

m) of

force is required to apply or release brake

handle.

If parking brake cannot be adjusted by turn-

ing handle, proceed as follows:

Release parking brake. Turn parking brake

handle counterclockwise as far as possible.

5

Lock Nuts

6

Adjustment Rod

Loosen lock nuts on rod. Slide rod slightly for-

ward. Tighten nuts.

Turn handle clockwise until parking brake is

properly adjusted.

Tools Needed:

1/2, 1-1/8 in

BRAKE

FLUID

3

4

5

6

1

2

1

Replace trailer hardware

only with SAE grade 5 hard-

ware of same type and size

as originally installed.

Block wheels when adjusting

parking brake.

Figure 3-8. Trailer Maintenance