5 troubleshooting, Troubleshooting, Figure 8 – troubleshooting guide – Maretron LLP FFM100 User Manual

Page 22: Ffm100 user’s manual

FFM100 User’s Manual

Page 18

Revision 1.2

5 Troubleshooting

If you notice unexpected operation of the Maretron FFM100, follow the troubleshooting

procedures in this section to remedy simple problems.

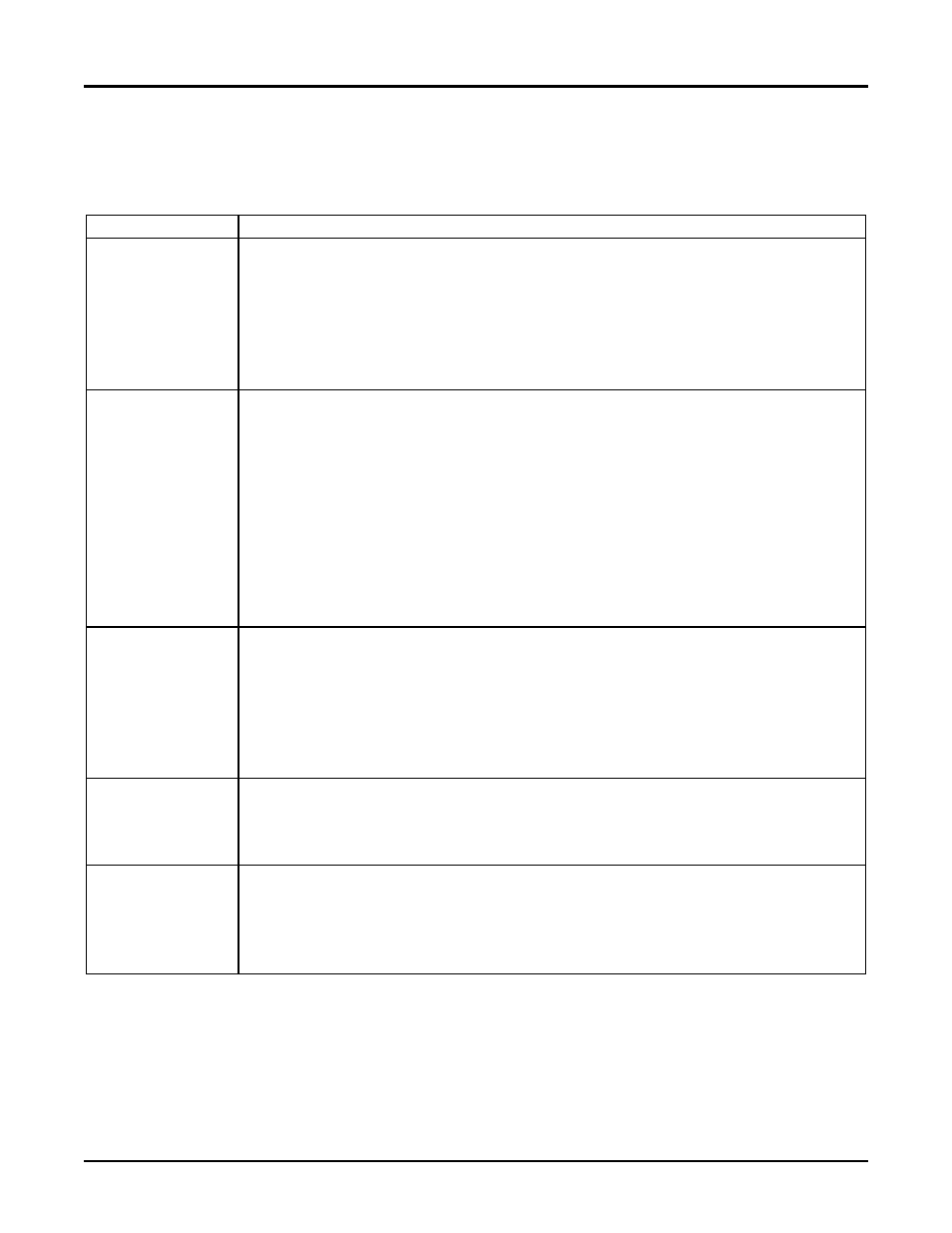

Symptom

Troubleshooting Procedure

No Fuel Flow

data visible on

NMEA 2000

®

network.

1. Ensure that the FFM100 is properly connected to the NMEA 2000

®

network.

2. Ensure that fluid flow sensors are properly connected to the FFM100.

3. Ensure that each channel that you wish to monitor is configured

correctly and that instance numbers are configured correctly.

4. Ensure that the FFM100 has the appropriate NMEA 2000 PGNs

enabled.

No Fluid

Temperature

data visible on

NMEA 2000

®

network.

1. If operating in the NMEA 2000

®

Mode, check the connection to the

NMEA 2000

®

interface (see Section 2.5.1) and tighten if necessary.

2. Ensure that power is supplied to the NMEA 2000

®

network. Proper

network power can be checked by measuring the voltage at an open

tee between NET-S and NET-C. The voltage should be between 9 and

16 volts.

3. Ensure that both trunk line terminators are in place. Proper network

termination can be checked by removing network power and

measuring the resistance at an open tee between NET-L and NET-H

signals. The resistance should read approximately 60 ohms (two 120

ohm terminators in parallel equals 60 ohms).

Fluid will not

flow through the

fluid flow

sensors

1. Check the meter for foreign matter blocking the rotors. Dismantle the

sensor and clean the rotors, then reassemble the sensor.

2. If a line strainer is installed, check to see whether it is blocked, and

clean if necessary.

3. Check the rotors to see if they are damaged, and replace if necessary.

4. Check the sensor connections to see if they are over-tightened, and

re-adjust if necessary.

Reduced flow

through the fluid

flow sensors

1. If a line strainer is installed, check to see if it is partially blocked, and

clean if necessary.

2. Ensure that the fluid being measured is less than 1000 centipoise

viscosity.

Inaccurate fluid

flow reading

1. Ensure that the fluid flow rate is within the minimum and maximum

specifications for the sensor.

2. Check for air in the system, and bleed if present.

3. Check the fluid flow sensor body and rotors for excess wear caused

by incorrect installation.

Figure 8 – Troubleshooting Guide

If these steps do not solve your problem, please contact Maretron Technical Support (refer to

Section 7 for contact information).