Control panel performance data specifications, Process and material thickness guide, Subject to change without notice.) – Miller Electric Arc Welding Power Source User Manual

Page 2

200

150

100

60

80

15

20

25 30

40

50

70

60

80 90 100

WELDING AMPERES

% DUTY CYCLE

DUTY CYCLE CHART

1

2

4

3

5

7

6

2

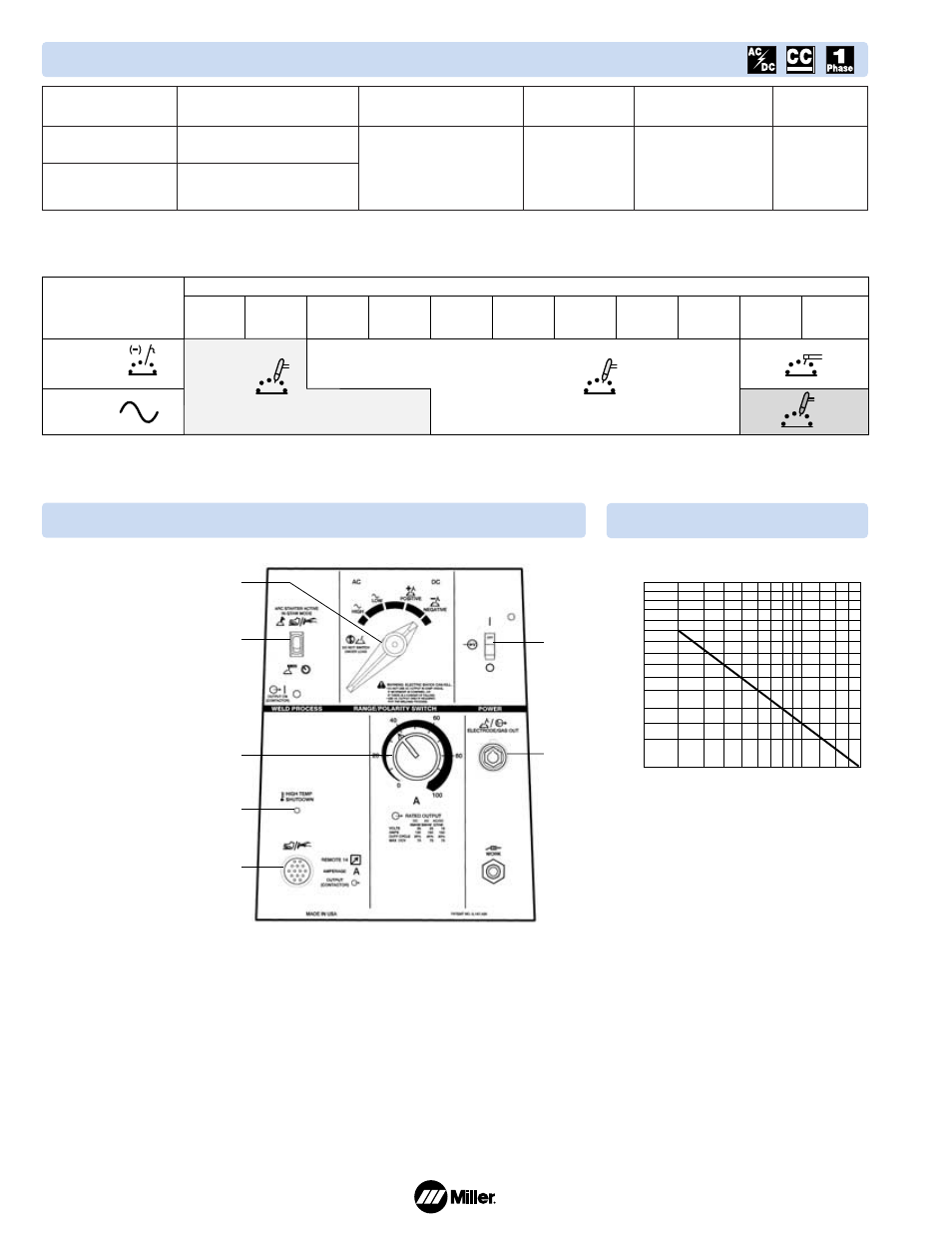

Control Panel

Performance Data

Specifications

(Subject to change without notice.)

1. Range/Polarity Switch

2. Process Switch

3. Amperage Control

4. High Temp Light

5. Remote Receptacle

6. Power Switch

7. International Flow-

Through Receptacle

Rated Output

at 20% Duty Cycle

TIG: 150 A at 15 VDC

150 A at 15 VAC

Stick:130 A at 25 VDC

150 A at 25 VAC

Welding Amperage Range

AC High

AC Low

DC

TIG Welding Range

50 – 165

20 – 50

30 – 160

Stick Welding Range

35 – 165

20 – 50

25 – 130

Max. Open-Circuit Voltage

78

Input Amps

at Rated Output

200 V 60 A

230 V 52 A

460 V 33 A

380 V 39 A

415 V 36 A

Dimensions

H: 18 in (457 mm)

W: 13 in (330 mm)

D: 25-1/2 in (648 mm)

Net Weight

140 lb (64 kg)

Process and Material Thickness Guide

Material and

Weld Output

22 ga

0.033 in

0.8 mm

Steel or

Stainless Steel

Aluminum

20 ga

0.036 in

0.9 mm

18 ga

0.048 in

1.2 mm

16 ga

0.06 in

1.5 mm

14 ga

0.07 in

1.8 mm

12 ga

0.1 in

2.5 mm

11 ga

0.125 in

3.2 mm

10 ga

0.14 in

3.6 mm

6 ga

0.186 in

4.8 mm

2 ga

0.25 in

6.3 mm

—

0.25+ in

6.3+ mm

Material Thickness

Electrode Negative

DCEN

TIG (GTAW)

TIG

(GTAW)

Stick

(SMAW)

AC

Not

Recommended

With

DCEP

Output

Difficult

TIG (GTAW)

Recommended