3. connecting optional auxiliary power plant – Miller Electric 500DX R User Manual

Page 30

OM-129 647 Page 26

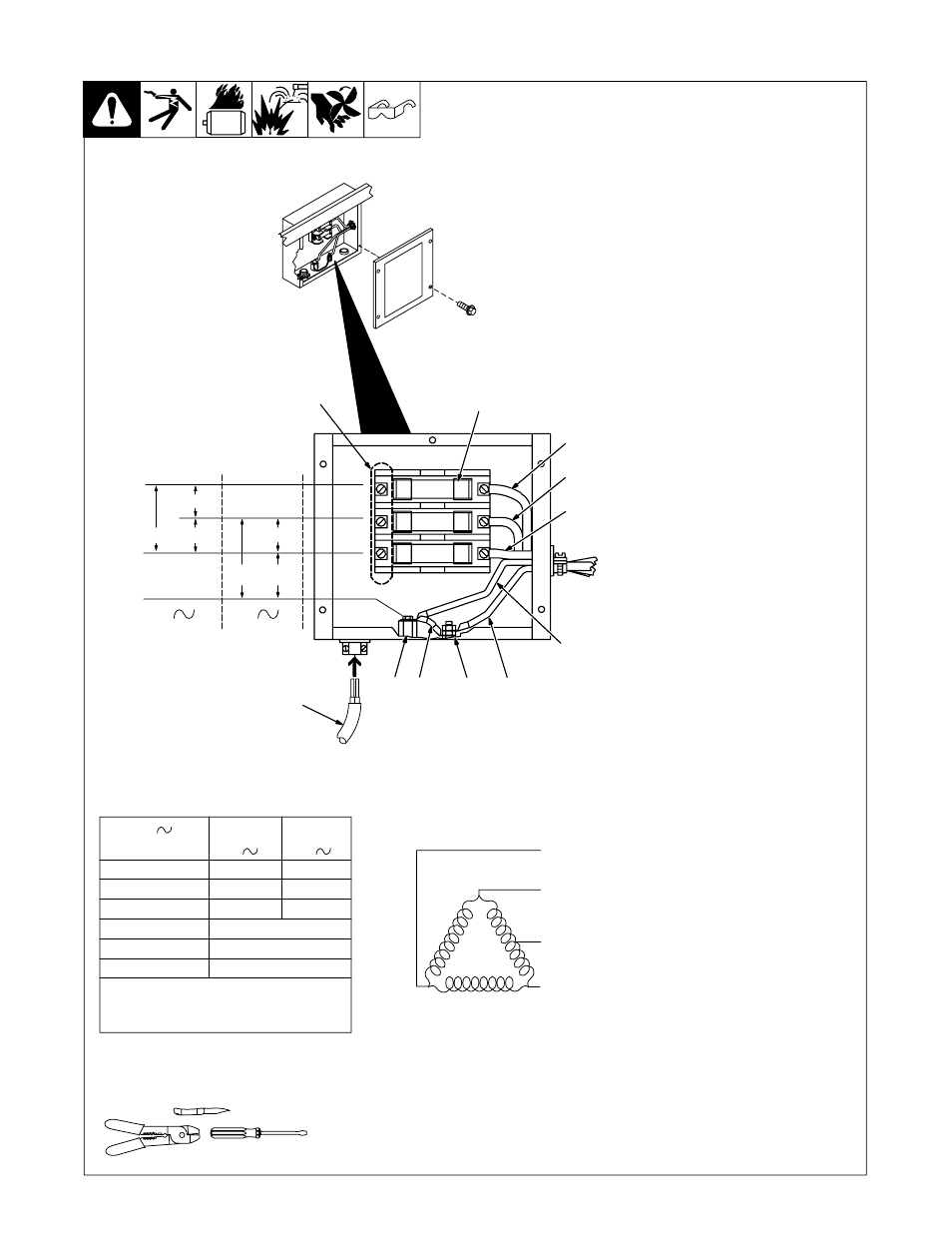

6-3. Connecting Optional Auxiliary Power Plant

Ref. S-180 187-A

Y Stop engine.

Y Power and weld outputs are

live at the same time. Discon-

nect or insulate unused

cables.

Have qualified person install

according to circuit diagram and

Auxiliary Power Guidelines Booklet

(M176 712).

Remove junction box cover.

1

Lead 93

2

Lead 92

3

Lead 91

4

Lead 90 (Neutral)

5

Lead 42 (Circuit Grounding

Lead)

Lead 42 connects to front panel

Ground stud.

6

Grounding Terminal

7

Jumper Lead 42

8

Isolated Neutral Terminal

Jumper 42 is connected to lead 90

at factory. Jumper 42 may be dis-

connected from neutral to meet

applicable electrical codes.

9

User-Supplied Leads

10 Load Terminals

Connect leads to terminals.

11 Fuses F1, F2, And F3

F1, F2, and F3 protect each load

line from overload.

.

Set Engine Control switch to

Run when using auxiliary

power.

4

5

7

8

9

6

10

11

Tools Needed:

93

91

90

92

240V

120V

120V

240V

240V

240V

1

3

Volts

Amps

KVA/KW

Single

120/240

31

7.5

Three

240

24

10

60 Hz

Frequency

Engine Speed

Max. Fuse Size

35 Amperes

1850 RPM

AC

Phase

1

Phase

3

Output

Lead 42 connects to GROUND stud on front of

unit.

Jumper 42 is connected to 90 at factory.

F3

F2

F1

1

2

3

7

8