Attaching the clutch cable, Final clutch adjustment, Tire pressure – MTD 410 Thru 420 User Manual

Page 7

7

•

Slide the rubber washer on the unthreaded end of

the handle adjustment rod. Insert the end of the

handle adjustment rod into the positioner bracket

beneath the handle, on top of the tine shield. See

Figure 7. Secure with hairpin clip.

•

Reinstall the nut and T-handle.

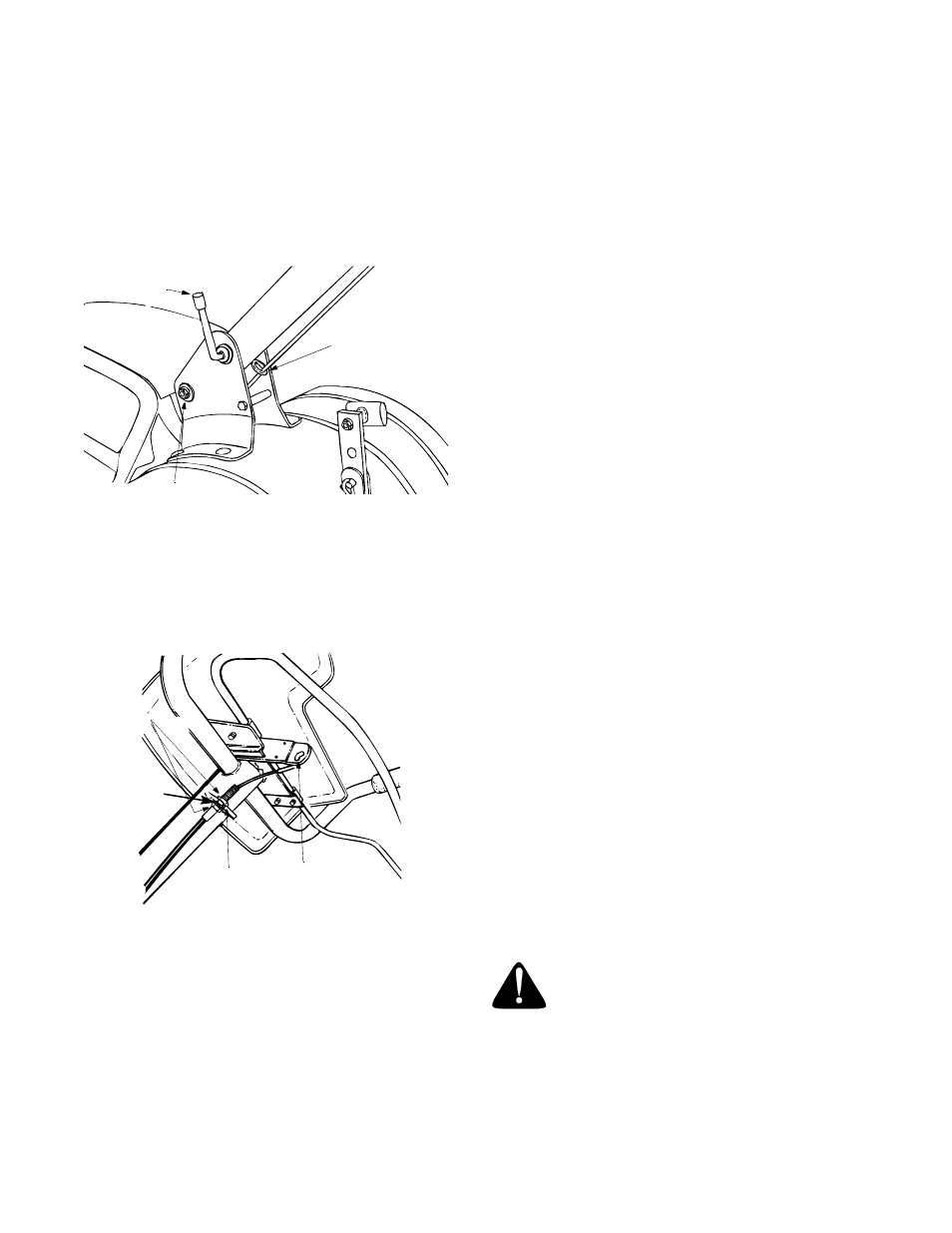

Attaching The Clutch Cable

Figure 8

•

Route the clutch cable underneath the handle and

through the cable clip. Be careful not to bend or

kink the cable. Refer to Figure 8. Remove one hex

nut from the threaded casing on the end of the

cable. See Figure 9.

Figure 9 Viewed beneath handle panel.

•

Slip the wire up through the slot on the cable

bracket underneath the handle. Push the end of the

casing up through the cable bracket. Rethread the

hex nut on the end of the cable. Do not tighten at

this time.

•

Pull the cable upwards to obtain slack, and, from

right to left, hook the “Z” end of the cable into the

bracket on the clutch control (beneath the handle

panel) as shown in Figure 9. Tighten the nut

against the cable bracket.

NOTE: Do not overtighten control wire. Too much

tension may cause it to break.

Final Clutch Adjustment

IMPORTANT:

Service the engine with oil and gasoline

before checking this adjustment. Refer to the separate

engine manual packed with your tiller.

•

Position the tiller so the front counterweight is

against a solid object, such as a wall. With the gear

selection lever in NEUTRAL, start the engine. Refer

to Operation section.

NOTE: Keep hands out of belt area while unit is

operating.

•

Standing on the right side of the tiller, visually

examine the belt (inside the belt cover). It should

not be turning.

If the belt turns with the unit in neutral, adjust by

moving the hex nut below the cable bracket down a

few turns. See Figure 9. Tighten the upper hex nut

against the bracket.

•

Now move the shift lever to FORWARD (Wheels

Forward) position. Carefully engage the clutch by

squeezing the clutch handle against the handle.

The wheels should spin.

•

If the wheels do not spin with the unit in

forward, adjust by moving the hex nut which is

above the cable bracket up a few turns. Tighten the

bottom hex nut against the bracket.

Recheck both adjustments, and readjust as necessary.

Make certain hex nuts at cable bracket are tight (do not

overtighten control cable).

NOTE: If additional adjustment is required, it may be

necessary to remove the belt cover, and move the hex

nuts at the other end of the clutch cable to increase belt

tension.

Tire Pressure

The tires on your unit may be over-inflated for shipping

purposes. Reduce the tire pressure before operating

the unit. Recommended operating tire pressure is

approximately 14 p.s.i. on 14 inch tires and 20 p.s.i. on

16 inch tires.(Check sidewall of tire for tire

manufacturer’s recommended pressure).

WARNING: Maximum tire pressure under

any circumstances is 30 p.s.i. Equal tire

pressure should be maintained on both

tires.

Handle

Adjustment

Lock

Cable

Clip

Flange Lock Nut

Washer

Hex

Nuts

Slot in

Cable

Bracket

“Z” End

of Cable

Lock