7. connecting weld cable, 8. installing and threading welding wire – Miller Electric SuitCase 8VS User Manual

Page 18

OM-1599 Page 14

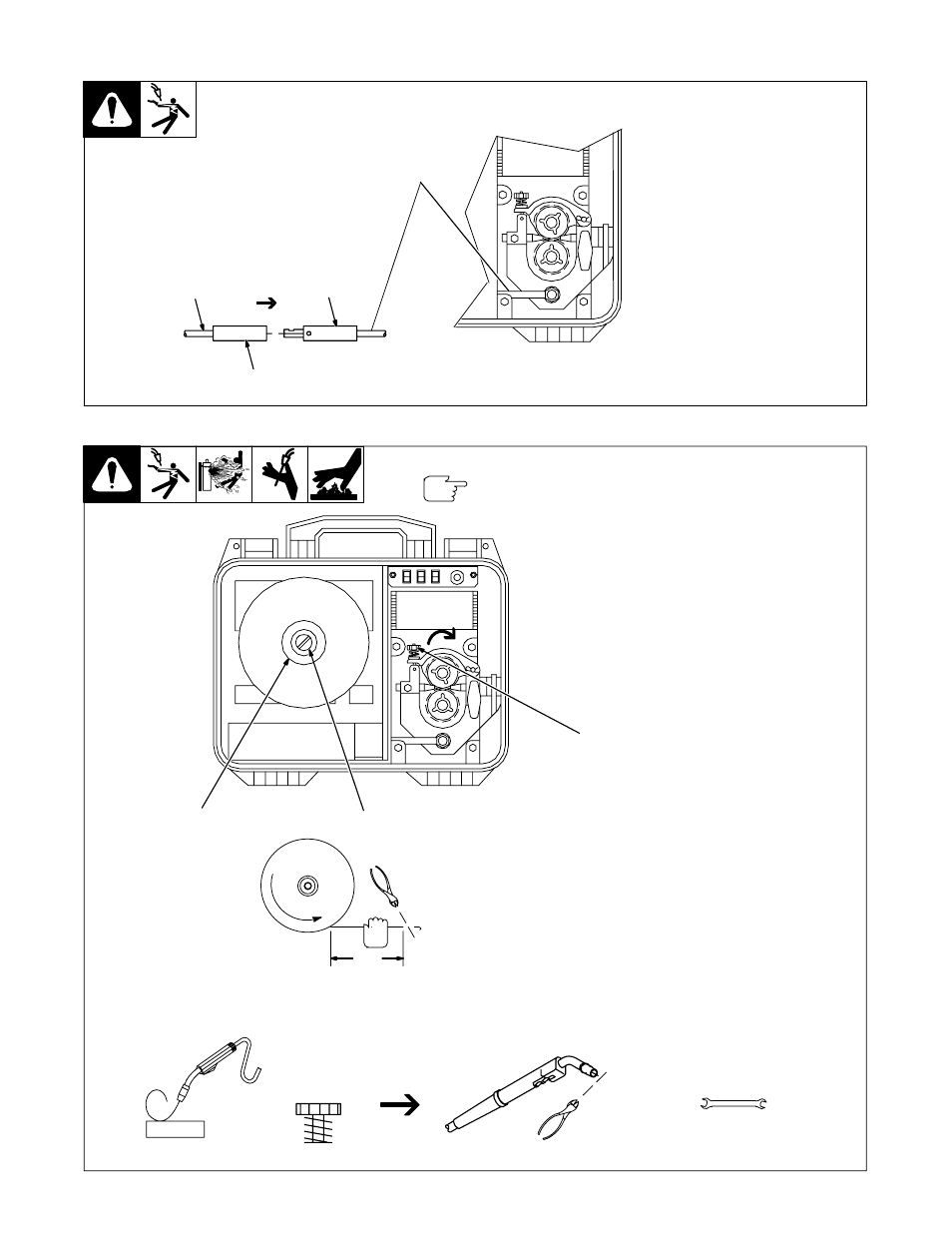

4-7. Connecting Weld Cable

Ref. 132 808-F / Ref. 802 706

Y Turn Off wire feeder and

welding power source. Stop

engine on welding

generator.

1

User-Suppled Weld Cable

Follow wire manufacturer’s recom-

mendations for weld cable polarity.

2

User-Suppled Male Connector

3

User-Suppled Female

Connector

Push female connector over male

connector, and turn 1/4 turn clock-

wise.

2

1

3

From Wire Feeder

Internal Side View

4-8. Installing And Threading Welding Wire

802 706-A / Ref. ST-159 048-A / S-0627-A

Installing Wire And Adjusting

Hub Tension:

1

Retaining Nut

2

Hub Tension Adjustment Nut

Remove retaining ring, and install

spool so hub pin fits spool hole. Re-

install retaining nut.

Adjust tension nut so only a slight

force is needed to turn spool.

Threading Welding Wire:

3

Pressure Assembly

Adjustment Knob

Lay gun cable out straight.

Open pressure assembly, hold wire

tightly, and cut off end. Push wire

through guides into gun.

Close and tighten pressure assem-

bly. Press Jog switch until wire

comes out gun.

Feed wire against wooden surface,

and tighten knob so wire does not

slip.

Cut off wire, and close door.

Tools Needed:

9/16 in

Pull and hold wire; cut off end.

Hold wire tightly to keep it

from unraveling.

6 in

(150 mm)

1

2

3

WOOD

Tighten

Clockwise