2. controls (ce models), Section 6 − maintenance and troubleshooting, 1. routine maintenance – Miller Electric 852 User Manual

Page 28

.

A complete Parts List is available at www.MillerWelds.com

OM-222 Page 24

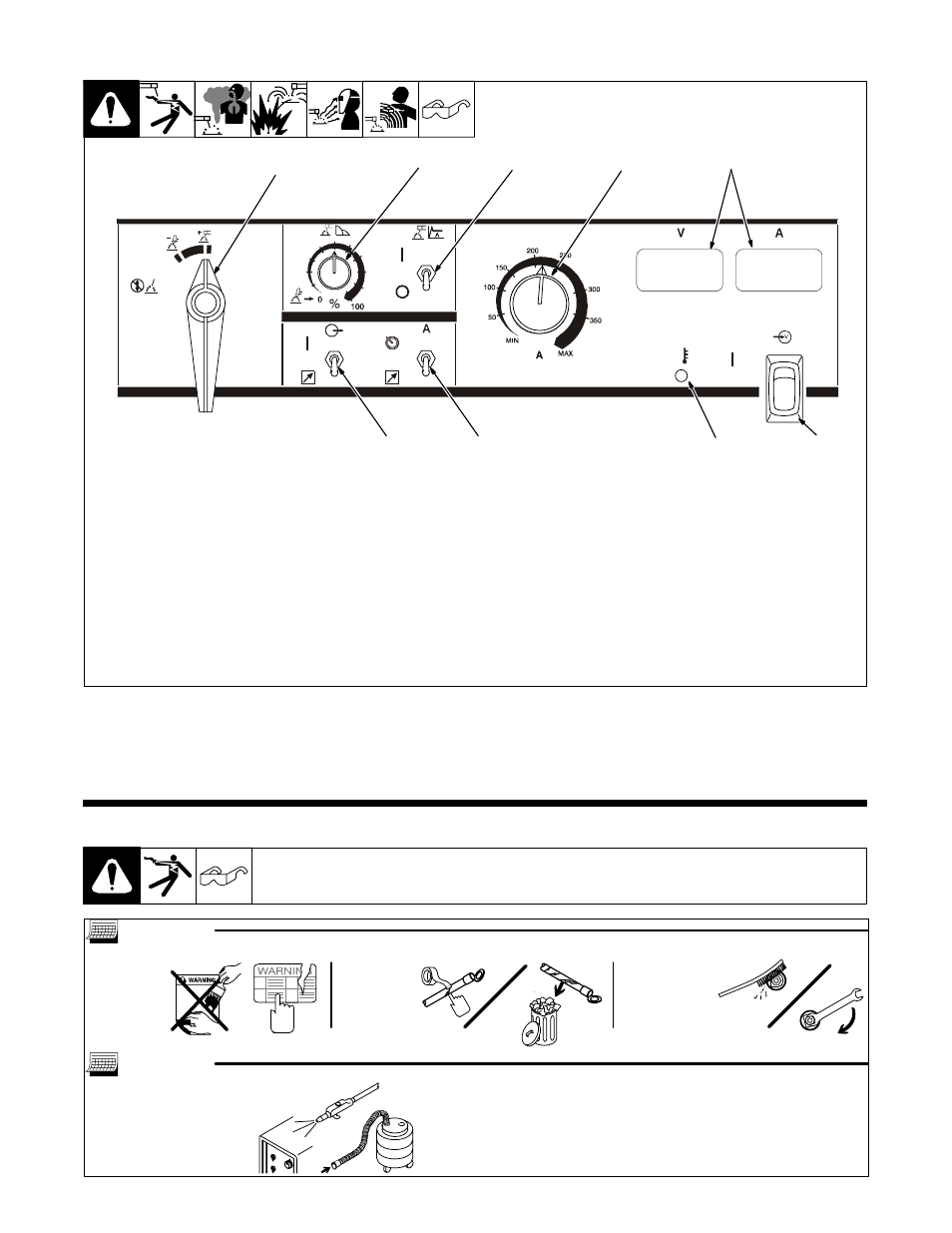

5-2. Controls (CE Models)

1

Polarity Selector Switch (Optional On 50

Hz Models)

To change polarity on models not equipped

with a Polarity Selector switch, reverse work

and electrode cables at the weld output termi-

nals (see Section 4-8).

Y Turn Off Power before reversing

cables.

2

Arc Force (Dig) Control

Control increases SMAW short-circuit amper-

age which allows the operator to use a very

short arc length without sticking the electrode.

Set control at 0 for normal welding amperage.

Turn clockwise to increase short-circuit

amperage.

3

Hot Start Switch

Turn switch On for SMAW and Off for GTAW

welding.

4

Amperage Adjustment Control

5

Digital Meters (Optional)

6

Power Switch With Indicator Light

7

High Temperature Shutdown Light

8

Remote Amperage Control Switch

For front panel control, place switch in Panel

position. For remote control, place switch in

Remote position, and connect remote device

Output Switch (Contactor)

For front panel control of output, place switch

in Panel position. For remote control of output,

place switch in Remote position, and connect

remote device (see Section 4-11).

Y Turn Off power before connecting re-

mote device.

Ref. ST-173 450-B

300 Amp Model Shown

1

2

8

9

4

6

7

3

5

SECTION 6 − MAINTENANCE AND TROUBLESHOOTING

6-1. Routine Maintenance

Y Disconnect power before maintaining.

3 Months

Replace

unreadable

labels.

Repair or

replace

cracked

weld cable.

Clean and

tighten weld

terminals.

6 Months

Blow out or

vacuum inside.

During heavy

service, clean monthly.

OR