Propeller inspection and maintenance, Ab c – Mercury Marine 90-830296005 User Manual

Page 6

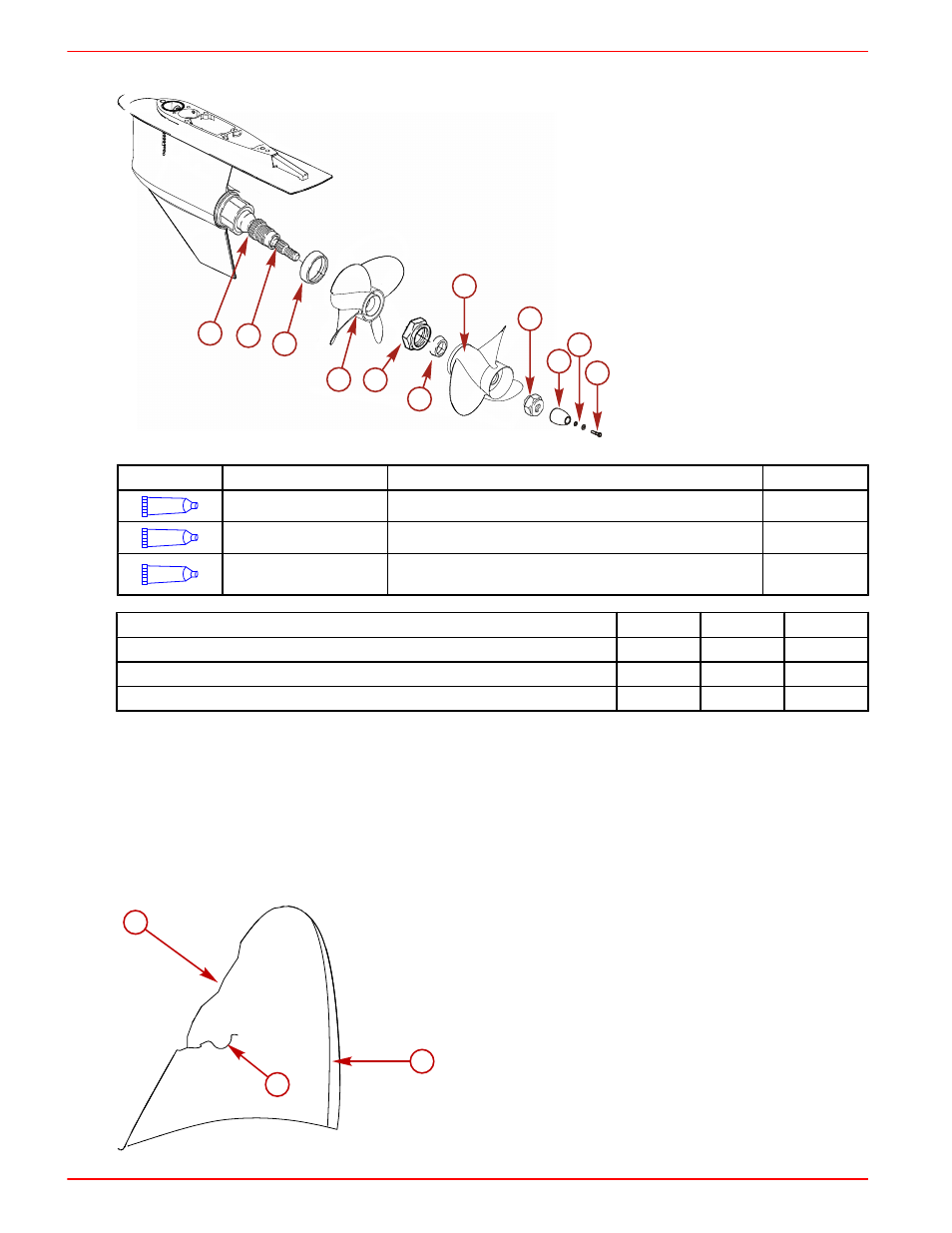

PROPELLER INSTALLATION INSTRUCTIONS

Page 6 / 7

90-830296005 FEBRUARY 2010

7. Secure it with the aft propeller nut and tighten to the specified torque.

a -

Outer propeller shaft

b -

Inner propeller shaft

c -

Forward thrust hub

d -

Forward propeller

e -

Forward propeller nut

f -

Aft thrust hub

g -

Aft propeller

h -

Aft propeller nut

i -

Anode

j -

Washers

k -

Screw

Tube Ref No.

Description

Where Used

Part No.

34

Special Lubricant 101

Propeller shaft splines

92-802865Q02

94

Anti-Corrosion Grease

Propeller shaft splines

92-802867Q 1

95

2-4-C Marine Lubricant

with Teflon

Propeller shaft splines

92-802859A 1

Description

Nm

lb‑in.

lb‑ft

Forward propeller nut

136

100

Aft propeller nut

81

60

Anode screw

27

20

IMPORTANT: Check the tightness of both propellers after 20 hours of operation. Tighten the propeller nuts if necessary.

Do not operate the vessel with a loose propeller.

Propeller Inspection and Maintenance

•

Inspect the leading edge of the propeller frequently for nicks, gouges, and damage.

•

Propellers with large, deep dents, gouges, or torn metal should be replaced or repaired.

•

Mineral deposits on stainless steel propellers can be caused by an inoperative or missing MerCathode system.

NOTE: Mineral deposits can be removed with household cleaners such as vinegar or other cleaners that remove lime and

mineral deposits.

a -

Leading edge

b -

Fatigue crack

c -

Cup

a

b

c

d

e

f

g

h

43655

i

j

k

a

b

c

6403