2. equipment connection diagrams – Miller Electric D-75S User Manual

Page 17

OM-228 322 Page 13

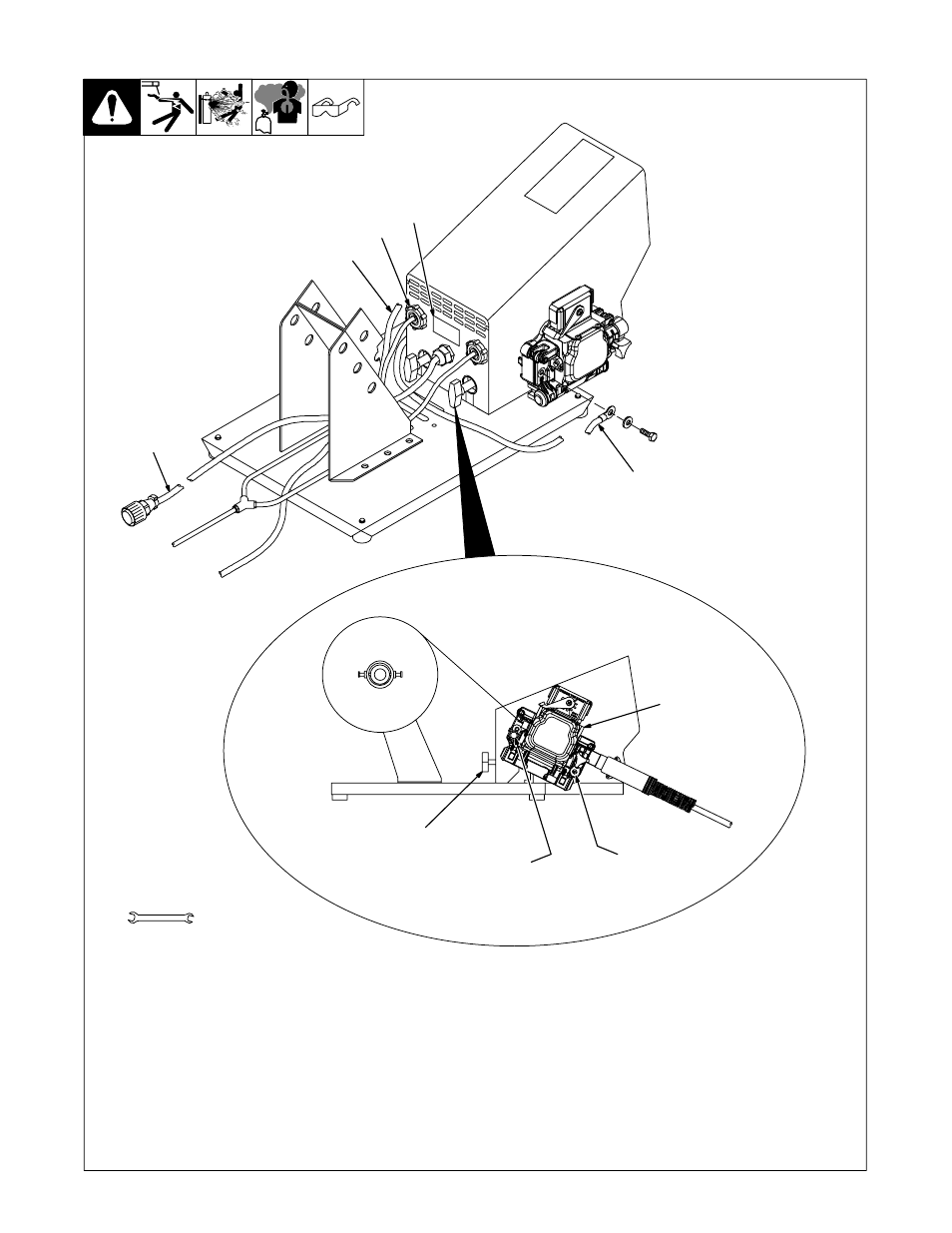

5-3. Rear Panel Connections And Rotating Drive Assembly

804 557-B / 804 184-B

2

1

14-Pin Control Cable - 10 Ft (3.0 m)

2

Shielding Gas Valve Fittings

Requires fitting with 5/8-18 right-hand

threads. Connect customer-supplied gas

hose.

3

Jumper Weld Cable

.

If welding at 350 amps or less, connect

jumper weld cable to connection point

B. Route cable around back of feeder.

(See illustration).

.

If welding at 350 amps or more, con-

nect jumper weld cable to connection

point A. Route cable around front of

feeder.

Left side of drive assembly has a screw to

secure jumper weld cable at connection

point B. To move jumper weld cable to con-

nection point A remove screw from point B

to use in point A.

Right side of drive assembly has screws to

secure jumper weld cable and weld cable to

connection points A and B.

4

Weld Cable

Connect weld cable to connection point A

on right side of drive assembly.

5

Drive Assembly

6

Drive Assembly Rotation Knob

To rotate the drive assembly, loosen drive

assembly rotation knob, rotate drive as-

sembly, and tighten knob.

7

Rating Label Location

9/16, 5/8 in

Tools Needed:

1

7

3

5

6

Connection

Point A

Connection

Point B

Left Side Shown

4