Control panel, Typical installations – Miller Electric S-32S User Manual

Page 2

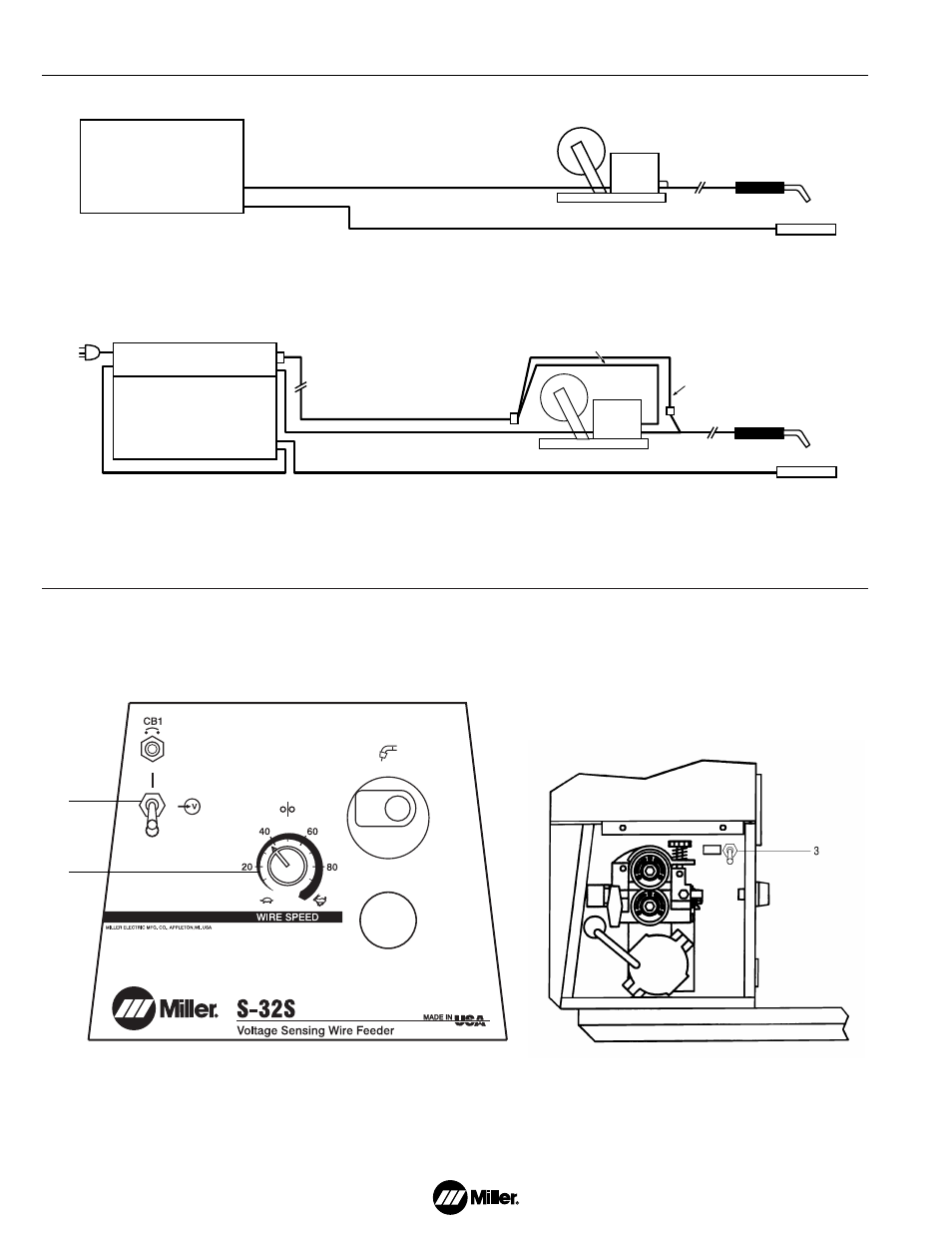

Control Panel

2

Work

BASIC SET-UP -– HOT WIRE

For MIG welding, use the

optional Gas Solenoid Valve.

Constant-Current

and Constant-Voltage

DC Power Sources

Electrode/Welding Cable

Electrode/Welding Cable

Remote Contactor Cord

Work

For MIG welding, use the

optional Gas Solenoid Valve.

WITH OPTIONAL EXTERNAL SECONDARY CONTACTOR

-– COLD WIRE

Note: The secondary contactor can be wired to operate off 115 VAC or powered

off a 12 VDC battery of an engine driven welder.

10 ft. (3 m) 115 VAC Primary Cord (Connect to power source 115 VAC supply, if available.)

115 VAC/12 VDC

Secondary Contactor

Electrode/Welding Cable

To Wire Feeder Trigger Receptacle

To Gun Trigger

Constant-Current

DC Power Sources

Not Having a Weld

Output Contactor

2

1

Typical Installations

1. Power Control Switch

2. Wire Speed Control

3. CC/CV Switch

- OM-2241 (32 pages)

- ICE-27C (36 pages)

- Arc Welding Power Source (4 pages)

- INVISION 456 CC (44 pages)

- Welder (132 pages)

- SS-75D12 (44 pages)

- Load Bank LBP-350 (2 pages)

- OM-193 084E (36 pages)

- 750MPa (2 pages)

- APT-1000 (20 pages)

- OM-220 390F (48 pages)

- 271 (48 pages)

- Welding (32 pages)

- DC (72 pages)

- OM-129 (70 pages)

- XLi (24 pages)

- S-64 (36 pages)

- ICE-27T (36 pages)

- PipePro 304 (76 pages)

- AA40GBU (28 pages)

- D-64 (40 pages)

- Auto Arc XLT 165 (48 pages)

- 185 DX (56 pages)

- Big 40 DC/TIG 55500 A (8 pages)

- Big Blue 600D (60 pages)

- Millermatic 140 (60 pages)

- pmn (36 pages)

- LMSW Series (2 pages)

- 1250 (46 pages)

- Trailblazer Pro 350 D (8 pages)

- TS (76 pages)

- S-22P12 (28 pages)

- 602 (40 pages)

- Axcess 300 (56 pages)

- MOG-400 (40 pages)

- WC-24 (20 pages)

- Big Blue 502P (64 pages)

- Dimension 1000 (44 pages)

- DS-74DX12 (52 pages)

- 350 VS (36 pages)

- 24A (32 pages)

- GA-16C (12 pages)

- Big Blue 502D (116 pages)

- OM-229 038D (36 pages)