Mitsumi electronic CMY-R100VBK User Manual

Page 3

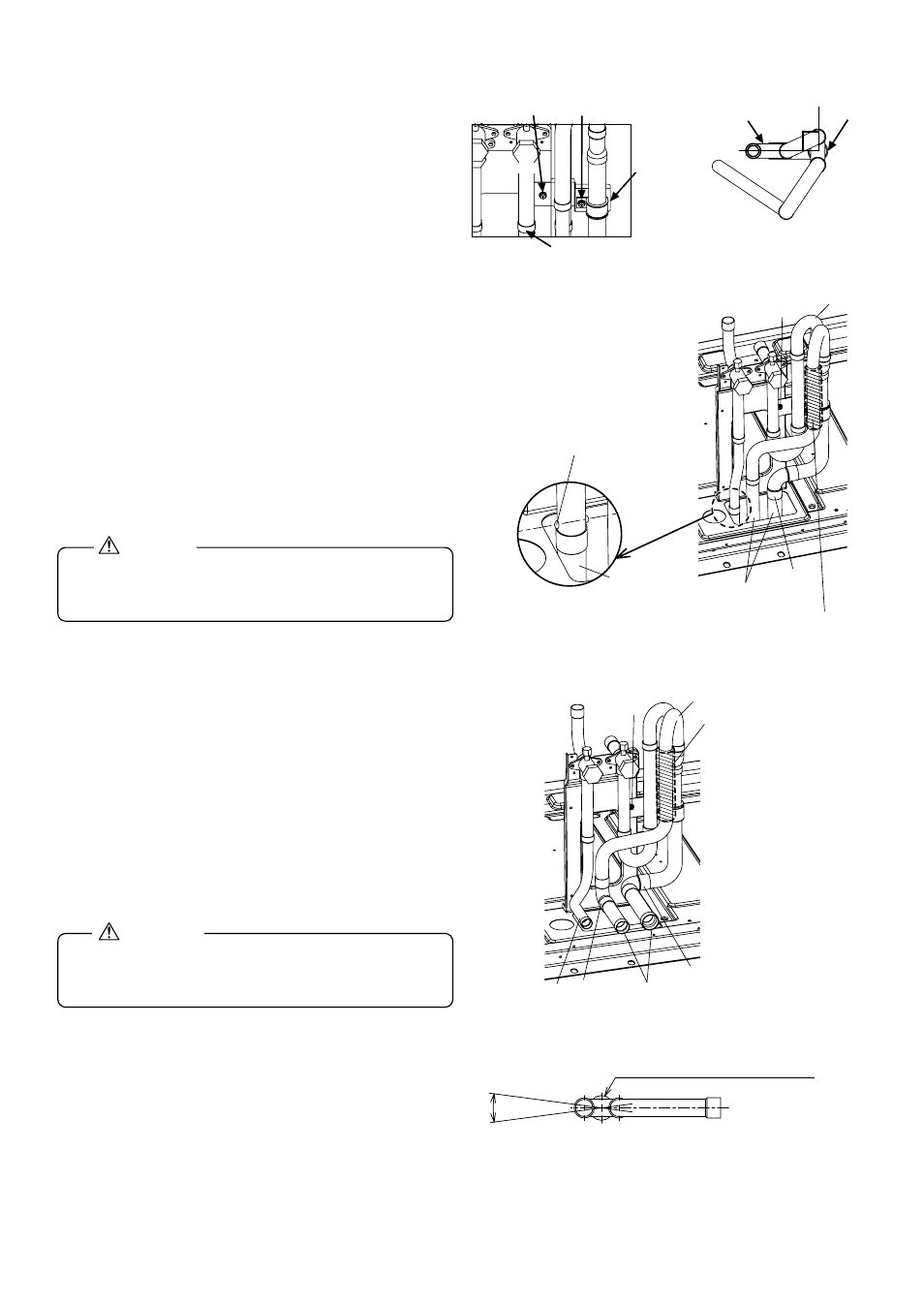

(3) Routing the pipe through the bottom

(1) Braze item

7

high-pressure pipe to the stop valve so that the

dimples on the pipe are parallel to the edge of the cutout hole.

Expand the end of the field-supplied pipes, and braze them

to item

7

high-pressure pipe.

(2) Attach item

1

low-pressure twinning kit to the sheet metal of the

control valve with item

3

screw, and braze it to the control valve.

(3) Braze item

5

or

6

elbow pipe to the field-supplied pipe first,

and then braze it to item

1

low-pressure twinning kit.

(4) Flare the field-supplied pipe end, and braze the pipe to the

low-pressure pipe in the middle.

(5) Wrap the pipe in front of item

1

low-pressure twinning kit with item

9

pipe cover, and attach compressor cables to item

9

pipe cover with

item

M

cable tie to keep them out of direct contact with the pipes.

Twinning pipe on the high-pressure side

±

15

˚

Slope of the twinning pipe is at an angle within

±

15˚ to the horizontal plane.

Note. Refer to the figure below for the installation position of the twinning pipe.

3

(4) Routing the pipe through the front

(1) Braze item

8

high-pressure pipe to the control valve.

(2) Attach item

1

low-pressure twinning kit to the sheet metal of the

control valve with item

3

screw, and braze it to the control valve.

(3) Braze item

5

or

6

elbow pipe to the field-supplied pipe first,

and then braze it to item

1

low-pressure twinning kit.

(4) Braze either item

4

or

5

elbow pipe to the low-pressure pipe in

the middle.

(5) Wrap the pipe in front of item

1

low-pressure twinning kit with

item

9

pipe cover, and attach compressor cables to item

9

pipe

cover with item

M

cable tie to keep them out of direct contact

with the pipes.

1

3

5

,

6

Field-supplied pipes

Field-supplied

pipes

Connect the pipe so that the

dimples on the

7

high pressure

pipe are on an imaginary line

parallel to the edge of the

cutout hole.

9

Wrap the pipe cover here.

Attach compressor cables to

Pipe cover with Cable tie

to keep them out of direct

contact with the pipes.

1

3

5

,

6

4

,

5

8

Field-supplied pipes

9

Wrap the pipe cover here.

Attach compressor cables to

Pipe cover with Cable tie

to keep them out of direct

contact with the pipes.

· Before heating the pipes, place a wet towel on the control valve to

keep its temperature below 120 ˚C [248˚F].

· Direct the flame away from the cables and sheet metals inside the

unit so as not to burn them.

CAUTION

· Before heating the pipes, place a wet towel on the control valve to

keep its temperature below 120 ˚C [248˚F].

· Direct the flame away from the cables and sheet metals inside the

unit so as not to burn them.

CAUTION

(2) Low-pressure twinning kit in CMY-R100VBK

Use either

F

or

G

in table 1,(1) Package Contents

depending on the size of the pipe at the control valve on

the unit to be combined with. Attach items

H

,

I

, and

J

to the stop valve sheet metal and then to the low-pressure

twinning kit to hold it into place.

1. Attach item

J

to the stop valve sheet metal.

2. Attach the packing and saddle.

3. Secure the low pressure twinning kit.

F

or

G

1

H

,

I

,

J

3

3

Section to be brazed field-supplied

Stop valve

(5) Slope of twinning pipes (high-pressure side only)

Make sure the slope of the twinning pipes are at an angle

within ±15˚ to the horizontal plane.

If the slope exceeds the specified angle, the unit may be

damaged.