MTD Y780 User Manual

Page 9

9

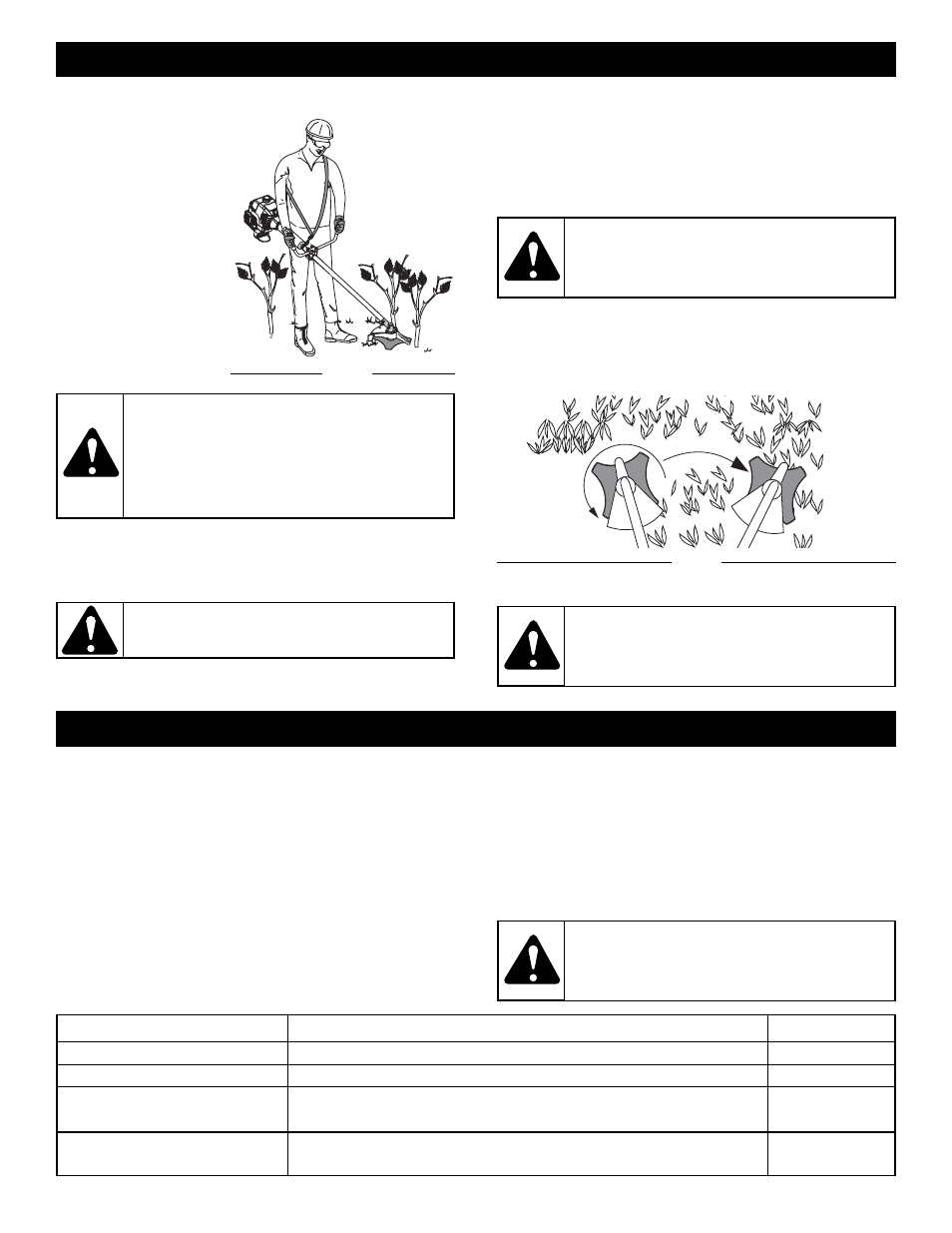

Cutting Blade Operating Tips

To establish a rhythmic

cutting procedure:

• Plant feet firmly,

comfortably apart.

• Bring the engine to full

throttle before entering

the material to be cut.

At full throttle the

blade has maximum

cutting power and is

less likely to bind, stall

or cause blade thrust

(which can result in

serious personal injury

to the operator or

others).

• Cut while swinging the upper part of your body from left to

right

• Always release the throttle trigger and allow the engine to

return to idle speed when not cutting.

• When you are finished, always unsnap the unit from the

harness before taking off the harness.

OPERATING INSTRUCTIONS

CAUTION:

Blade thrust may occur when the

spinning blade contacts an object that it does not

immediately cut. Blade thrust can be violent enough

to cause the unit and/or operator to be propelled in

any direction, and possibly lose control of the unit.

Blade thrust can occur without warning if the blade

snags, stalls or binds. This is more likely to occur in

areas where it is difficult to see the material being cut.

WARNING:

The blade continues to spin after the

engine is turned off. The coasting blade can

seriously cut you if accidentally touched.

Fig. 21

• Swing the unit in the opposite direction as the blade spins,

which increases the cutting action.

• After the return swing, move forward to the next area to be

cut plant your feet again.

• The cutting blade is designed with a second cutting edge.

You can use it by removing the blade, turning it upside

down, and reinstalling it.

To reduce the chance of material wrapping around the blade,

follow these steps:

• Cut at full throttle

• Swing the unit into material to be cut from your left to your

right (Fig. 22)

• Avoid the material just cut as you make the return swing

WARNING:

Do not sharpen the cutting blade.

Sharpening the blade can cause the blade tip to

break off while in use. This can result in severe

personal injury to yourself or others. Replace the

blade.

Fig. 22

MAINTENANCE AND REPAIR INSTRUCTIONS

MAINTENANCE SCHEDULE

Perform these required maintenance procedures at the

frequency stated in the table. These procedures should also be

a part of any seasonal tune-up.

NOTE:

Some maintenance procedures may require spe-

cial tools or skills. If you are unsure about these pro-

cedures take your unit to any non-road engine repair

establishment, individual or authorized service dealer.

NOTE:

Maintenance, replacement, or repair of the emis-

sion control devices and system may be performed

by any non-road engine repair establishment, individ-

ual or authorized service dealer.

In order to assure peak performance of your engine, inspection

of the engine exhaust port may be necessary after 50 hours of

operation. If you notice lost RPM, poor performance or general

lack of acceleration, this service may be required. If you feel

your engine is in need of this inspection, refer service to any

non-road engine repair establishment, individual or authorized

service dealer for repair. DO NOT attempt to perform this

process yourself as engine damage may result from

contaminants involved in the cleaning process for the port.

WARNING:

To prevent serious injury, never

perform maintenance or repairs with unit running.

Always service and repair a cool unit. Disconnect

the spark plug wire to ensure that the unit cannot

start.

CAUTION:

Do not clear away any cut material

with the engine running or blade turning. To avoid

serious personal injury, turn off the engine. Allow

the blade to stop before removing materials

wrapped around the blade shaft.

FREQUENCY

MAINTENANCE REQUIRED

REFER TO

Before starting engine

Fill fuel tank with fresh fuel

Page 3, 4

Every 10 hours

Clean and re-oil air filter

Page 11

Every 25 hours

Check and clean spark arrestor

Check spark plug condition and gap

Page 12

Page 13

Every 50 hours

Inspect exhaust port and spark arrestor screen for clogging or

obstruction to assure maximum performance levels

Page 12