Lubrication, Trouble shooting, Engine – MTD 390 Shown User Manual

Page 13: Cleaning the tine area, Belt removal and replacement

13

SECTION 6: MAINTAINING YOUR TILLER

Lubrication

WARNING: Always stop engine and

disconnect spark plug wire before

cleaning, lubricating or doing any kind of

work on tiller.

Pivot Points-Remove the belt cover and lubricate all

moving parts and pivot points at least once a season

using SAE 30 engine oil.

Chain Drive-The chain case is pre-lubricated and

sealed at the factory.

WARNING: Disconnect spark plug wire

and ground it against the engine before

performing any repairs or maintenance.

Trouble Shooting

Refer to the trouble shooting chart for more information.

Engine

Refer to the separate engine manual for all engine

maintenance instructions.

Maintain engine oil as instructed in the separate

engine manual packed with your unit. Read and follow

instructions carefully.

Service air cleaner every 25 hours under normal

conditions. Clean every few hours under extremely

dusty conditions. Poor engine performance and

flooding usually indicates that the air cleaner should be

serviced. To service the air cleaner, refer to the

separate engine manual packed with your unit.

IMPORTANT:

Never run your engine without air cleaner

completely assembled.

The spark plug should be cleaned and the gap reset

once a season. Spark plug replacement is

recommended at the start of each tilling season; check

engine manual for correct plug type and gap

specifications.

Clean the engine regularly with a cloth or brush.

Keep the cooling system (blower housing area) clean to

permit proper air circulation which is essential to engine

performance and life. Be certain to remove all dirt and

combustible debris from muffler area.

Cleaning The Tine Area

Clean the underside of the tine shield after each use.

The dirt washes off the tines easier if washed off

immediately instead of after it dries.

We do not recommend the use of pressure washers to

clean your unit. It may cause damage to electric

components, spindles, pulleys, bearings or the engine.

The use of pressure washers will result in shortened life

and reduce serviceability.

Belt Removal And Replacement

Your tiller has been engineered with belts made of

special material (Kevlar Tensile). They should not be

replaced with an off-the-shelf belt. If belt replacement is

required, order belt or belts by part number from your

nearest authorized service dealer.

Forward Drive Belt - Part No. 754-0428

Reverse Drive Belt (390 Only) - Part No. 754-0429

Reverse Drive Belt

(Model 390 Only)

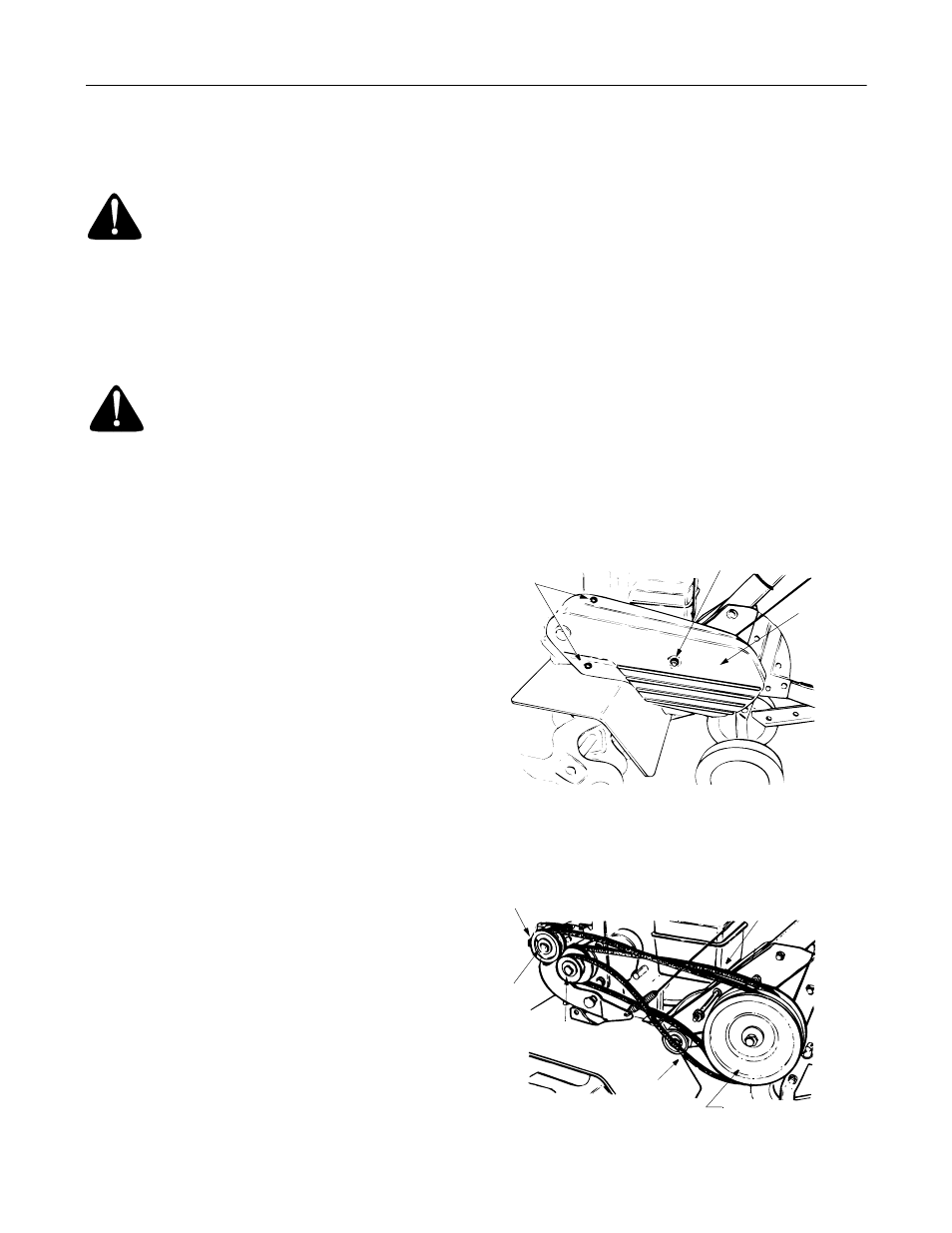

•

Disconnect and ground the spark plug wire against

the engine. Remove the belt cover from the left side

of the tiller as follows.

•

Remove two self-tapping screws and flat washers

from the front of belt cover. See Figure 16.

•

Remove the hex stop nut and flat washer from the

side of the belt cover. Remove belt cover.

Figure 16

•

Lift the belt off the transmission pulley.

•

Remove the hex nut which secures the reverse

idler pulley to the idler bracket. Slide idler pulley out

and remove the belt. See Figure 17.

Figure 17

Hex Nut and Washer

Self-Tapping

Screws

Belt

Cover

Engine

Pulley

Transmission

Pulley

Reverse Belt

Hex Nut

Forward

Belt

Reverse Idler Pulley

Model 390 Shown