8. connecting to weld output terminals, 9. selecting weld cable sizes – Miller Electric Big Blue 502P User Manual

Page 22

OM-491 Page 18

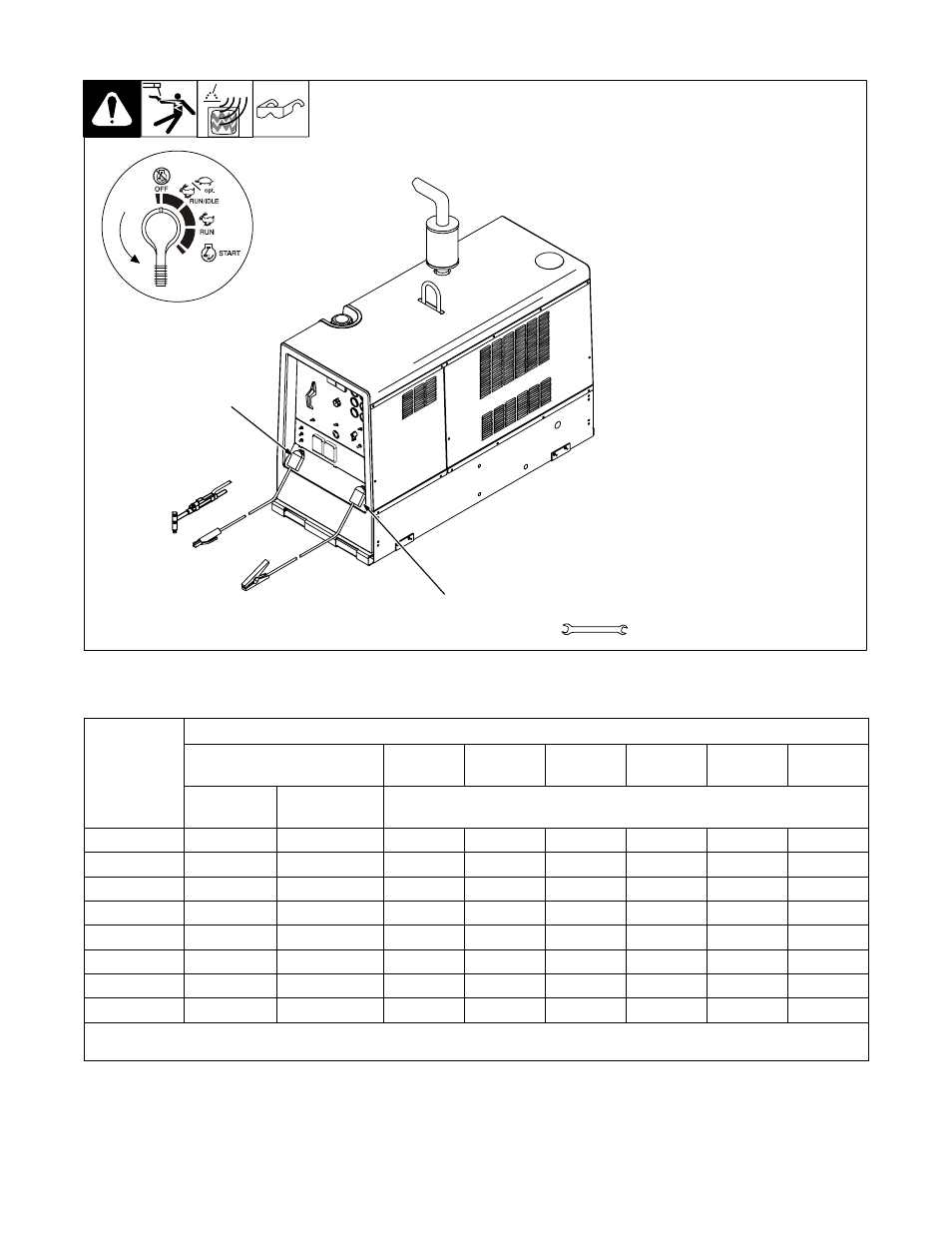

4-8. Connecting To Weld Output Terminals

Ref. 802 169-A

Y Stop engine.

1

Positive (+) Weld Output

Terminal

2

Negative (−) Weld Output Ter-

minal

For Stick and TIG welding Direct

Current Electrode Positive

(DCEP), connect work cable to −

terminal and electrode holder cable

to + terminal.

For Direct Current Electrode Nega-

tive (DCEN), reverse cable

connections.

If equipped with optional polarity

switch, connect electrode holder

cable to Electrode (−) terminal on

left and work cable to Work (+) ter-

minal on right.

Tools Needed:

2

3/4 in

OR

1

4-9. Selecting Weld Cable Sizes

Total Cable (Copper) Length In Weld Circuit Not Exceeding

Welding

Amperes

100 ft (30 m) Or Less

150 ft

(45 m)

200 ft

(60 m)

250 ft

(70 m)

300 ft

(90 m)

350 ft

(105 m)

400 ft

(120 m)

Amperes

10 − 60%

Duty Cycle

60 − 100%

Duty Cycle

10 − 100% Duty Cycle

100

4

4

4

3

2

1

1/0

1/0

150

3

3

2

1

1/0

2/0

3/0

3/0

200

3

2

1

1/0

2/0

3/0

4/0

4/0

250

2

1

1/0

2/0

3/0

4/0

2-2/0

2-2/0

300

1

1/0

2/0

3/0

4/0

2-2/0

2-3/0

2-3/0

350

1/0

2/0

3/0

4/0

2-2/0

2-3/0

2-3/0

2-4/0

400

1/0

2/0

3/0

4/0

2-2/0

2-3/0

2-4/0

2-4/0

500

2/0

3/0

4/0

2-2/0

2-3/0

2-4/0

3-3/0

3-3/0

*Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere. Contact your

distributor for the mm

2

equivalent weld cable sizes.

S-0007-E