Miller Electric CBI 801D User Manual

Page 39

OM-166 941 Page 34

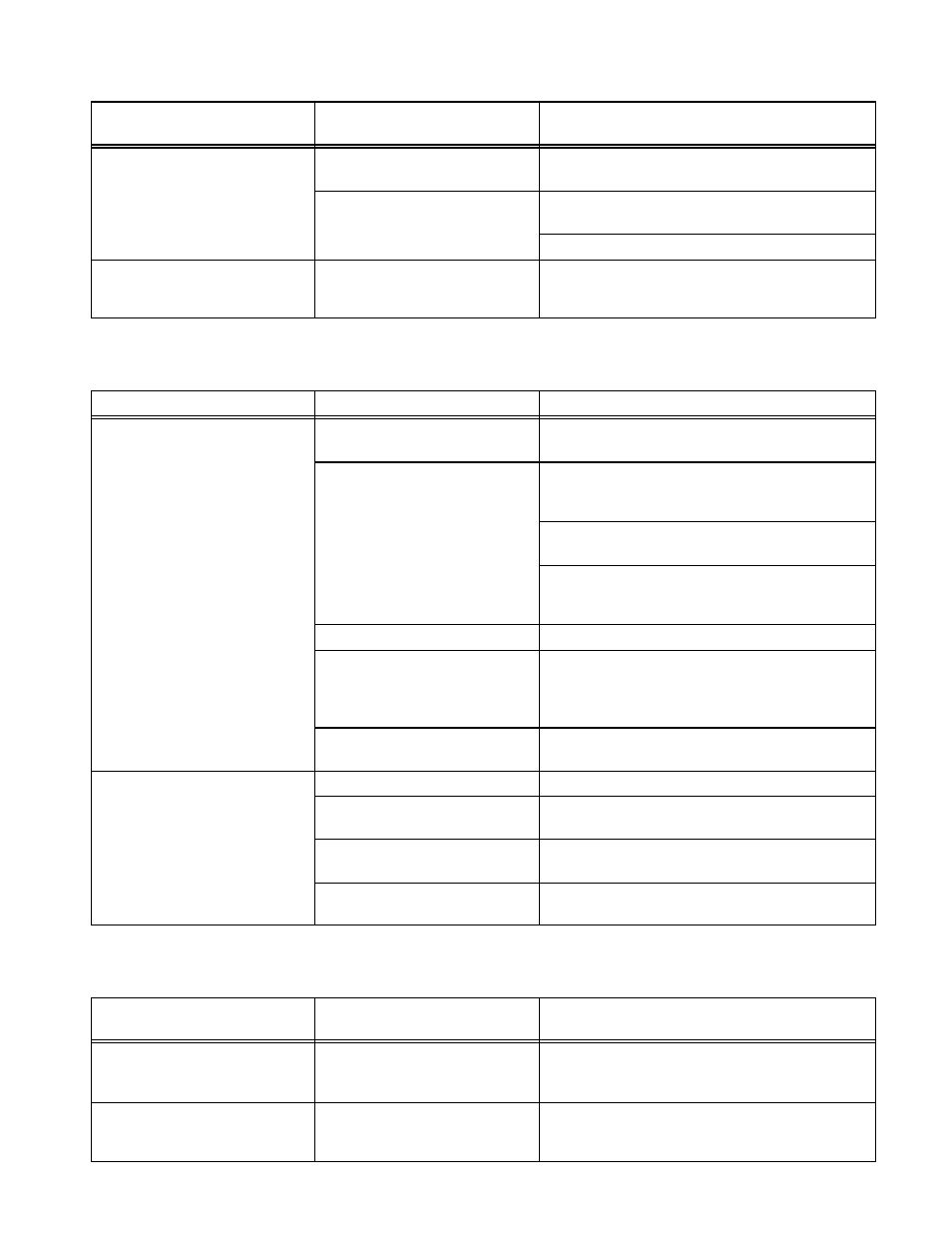

Table 9-2. Auxiliary Power Troubleshooting

AUXILIARY POWER

TROUBLE

PROBABLE CAUSE

REMEDY

No 120 volt output at 3T termi-

nals L and M.

Circuit breaker CB1 open.

Reset CB1 (see Section 9-3).

Poor contact between slip

rings and brushes.

Clean slip rings (see Section 8-9).

Replace brushes according to Section 8-9.

High auxiliary power output

voltage.

High engine speed.

Check and adjust engine speed according to

Section 8-8. (Maximum voltages should not

exceed 132 volts for single-phase power.)

Table 9-3. Engine Troubleshooting

TROUBLE

PROBABLE CAUSE

REMEDY

Engine does not start.

Out of fuel.

Fill fuel tank, and air vent fuel system (see En-

gine Manufacturer’s Manual.)

Battery problem.

Check engine battery charging system accord-

ing to engine service manual (not supplied with

engine).

Inspect electrical system (see Section 8-1). If

trouble is isolated to battery, replace it.

Jump start the engine using approved safety

practices and booster battery (see Section

9-2).

Engine Control switch S1.

Check S1, and replace if necessary.

Oil Pressure gauge/switch or

Oil Temperature gauge/switch

activated, or other engine

trouble.

See Sections 6-10 thru 6-11; see Engine Man-

ufacturer’s Manual (F4L-912 engine).

MS1 fuse F.

Check and replace F, if necessary (see Sec-

tion 9-3).

Engine suddenly shuts down.

Broken cooling belt.

Check and replace belt (see Section 6-15).

High oil temperature.

Check engine oil level and add oil if necessary;

check for cooling air flow obstructions.

Low oil pressure.

Check engine oil level, and add oil if necessary

(see Section 4-5).

MS1 fuse F.

Check and replace F if necessary (see Section

9-3).

Table 9-4. Air Compressor Troubleshooting

AIR COMPRESSOR

TROUBLE

CAUSE

REMEDY

Air compressor fails to build

pressure or builds pressure

slowly.

Engine air compressor.

Service air compressor. Contact nearest Au-

thorized Service Station/Service Distributor.

Pneumatic tools freeze up.

Moisture in compressed air.

Induce an antifreeze solution into the air sup-

ply. Contact nearest Authorized Service Sta-

tion/Service Distributor.