Operation loading the stapler/nailer, Direction for use, Maintenance – Global Machinery Company 300W User Manual

Page 7: Cleaning, Repairs

7

Operation

Loading the stapler/nailer

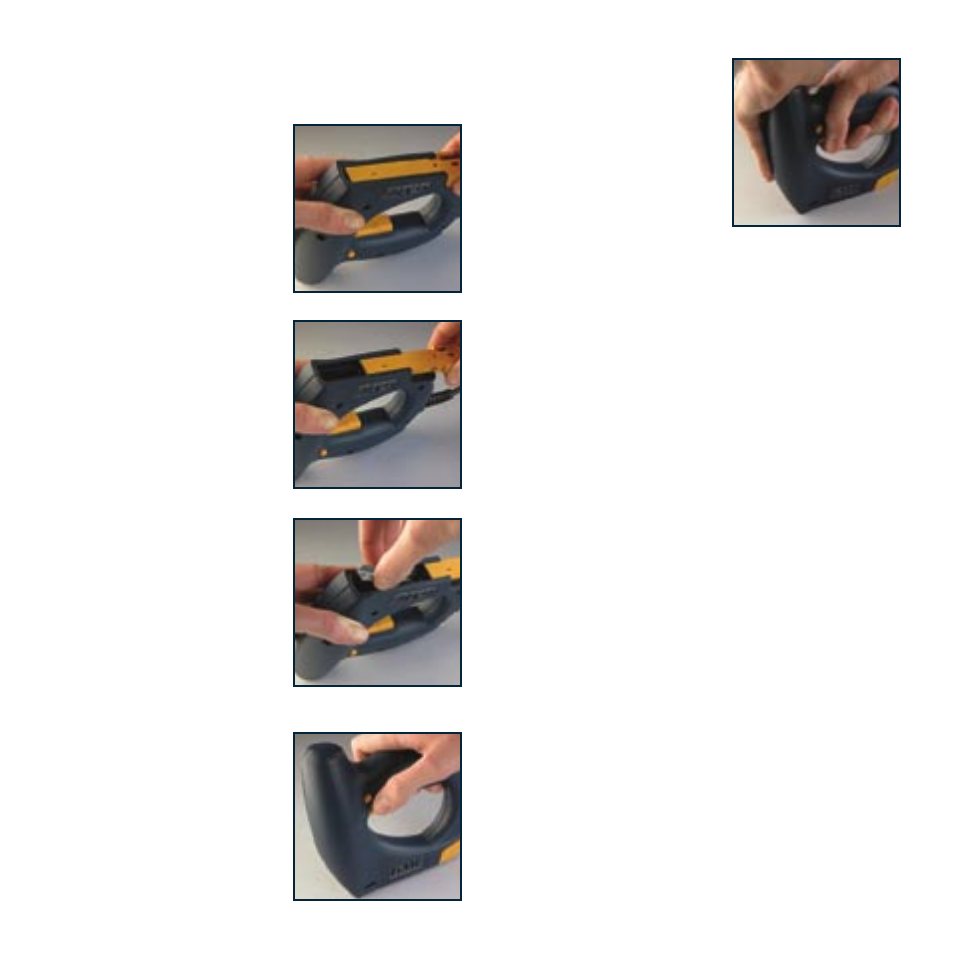

1. Squeeze and pull the release

button to unlock the stapler/

nailer. [Fig 1]

2. Use only staples or brad nails

recommended.

3. Hold the tool upside down,

squeeze the latch and slide

open the base. [Fig 2]

4. To load staples drop them in

the channel with the legs

facing upward and close the

base. To load brad nails,

drop them in the left side

of the channel with the “T”

head sitting on the slot base.

Close the base while making

sure that the nail strip stays

upright in the channel.

5. Make sure that the latch is

securely locked. [Fig 3]

WARNING:

To avoid personal

injury, keep fingers off the trigger

until you are ready to use the

stapler/nailer at anyone when the

stapler or brad nails are loaded.

Direction for use

WARNING:

Make sure your

finger is not on the trigger

when connecting the tool to the

power source.

1. Lock the safety lock on the

stapler/nailer. [Fig 4]

2. Make sure the tool is in good

working condition.

3. Unlock the safety lock.

4. Hold tool firmly with the

tacking mouth flat to the

working place forming a 90

degree angle. [Fig 5]

5. Squeeze the trigger to fire

the tool.

NOTE:

For better performance,

please hold the tool with one

hand on the “Housing Cap” while the other hand is ready

to fire the tool to prevent the kick back.

Maintenance

CAUTION:

Unplug the power cord from the tool before

carrying out maintenance or inspection.

1. Inspection of screw on each assembled part. Always

check for loose screws. If you find any, tighten them

securely. It is dangerous to continue using the tool

with loose screws.

2. Inspection of tacking mouth. The tacking mouth should

be kept clean at all times. Dirt or debris may cause

jamming.

Cleaning

1. Keep the tool’s air vents unclogged and clean at all

times.

2. Remove dust and dirt regularly. Cleaning is best done

with compressed air or a rag.

3. Never use caustic agents to clean plastic parts.

CAUTION:

Do not use cleaning agents to clean the plastic

part of the tool. A mild detergent on a damp cloth is

recommended. Water must never come in contact with the

tool.

Repairs

1. Only an authorized service centre should make any

repairs.

[Fig 1]

[Fig 2]

[Fig 3]

[Fig 4]

[Fig 5]