El (see, Lubricate unit, E) (figure 8) – Gravely 992042 19HP-144Z User Manual

Page 18

GB - 18

3. Return seat to operating position.

Clean Battery

Keep battery and its terminals clean. Inspect every 100

operating hours or monthly for best performance.

1. Remove battery from unit. See Remove Battery on

2. Clean terminals and battery cable ends with wire

brush.

3. Coat terminals with dielectric grease or petroleum

jelly.

4. Replace battery. See Replace Battery on page 17.

Charging the Battery

Battery Electrolyte First Aid

Follow First Aid directions for contact with battery fluid.

• External Contact: Flush with water.

• Eyes: Flush with water for at least 15 minutes and get

medical attention immediately!

• Internal Contact: Drink large quantities of water.

Follow with Milk of Magnesia, beaten egg or

vegetable oil. Get medical attention immediately!

In case of internal contact, DO NOT induce vomiting!

IMPORTANT: DO NOT fast charge. Charging at a higher

rate will damage or destroy battery. ONLY use an

automatic charger designed for use with your battery.

ALWAYS follow information provided on battery by

battery manufacturer. Contact battery manufacturer for

extensive instructions to charge battery.

1. Remove battery from unit. See Remove Battery on

2. Place battery on bench or other well-ventilated

place.

3. Connect positive (+) lead of charger to positive (+)

terminal, and negative (–) lead to negative (–)

terminal.

4. Charge battery according to charger and battery

manufacturers’ instructions.

5. Replace battery. See Replace Battery on page 17.

Jump Starting Battery

The unit used for jump starting should have a 12 volt

battery with at least 500 cold cranking amperes, and a

negatively grounded system.

NOTE: Ensure battery is not frozen. If the fluid is frozen,

remove battery from unit and allow it to thaw before

charging.

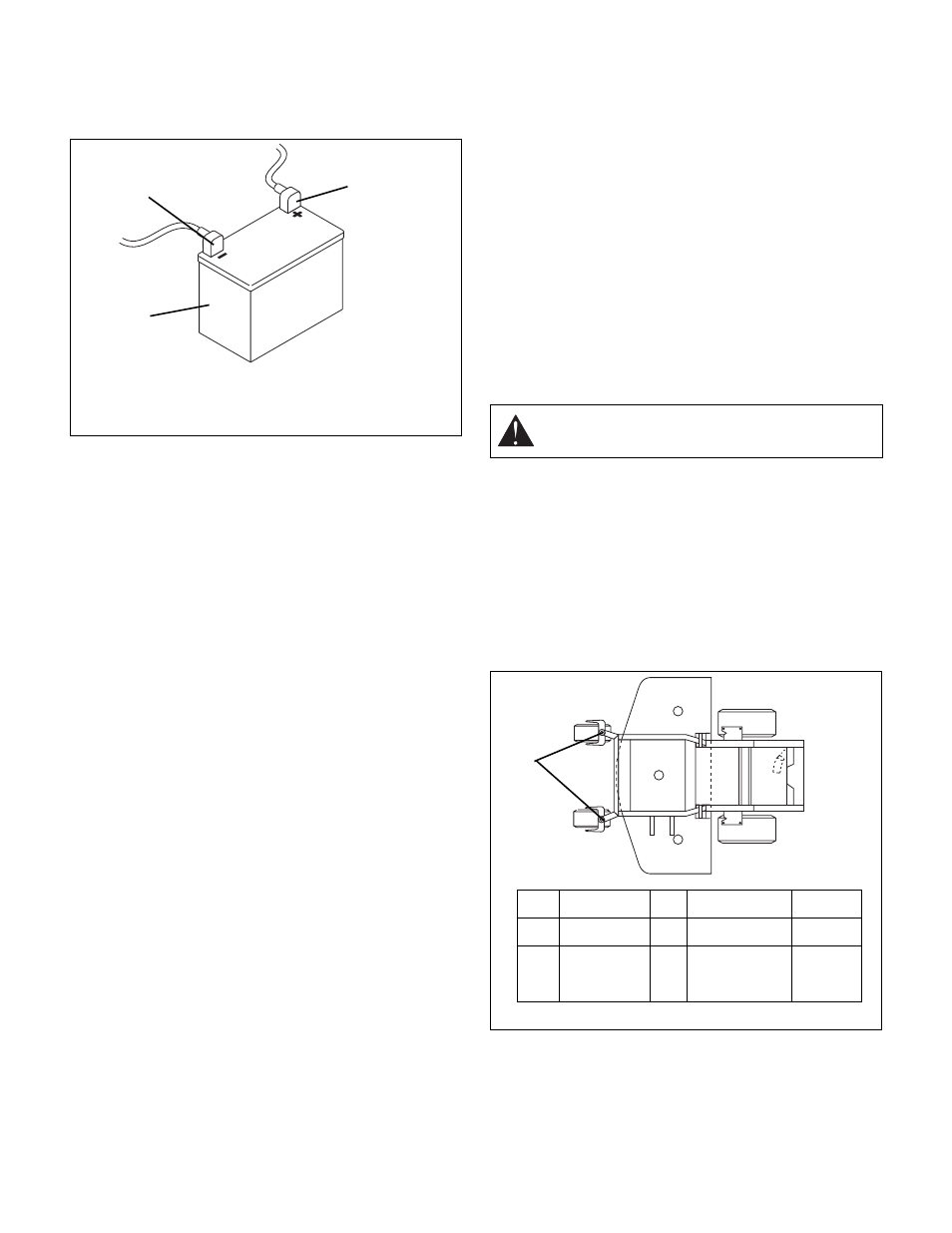

1. Connect the positive (+) jumper cable to the positive

terminal of the discharged battery (Figure 8).

2. Connect the other end of the same jumper cable to

the positive (+) terminal of the booster battery.

3. Connect one end of the second jumper cable to the

negative (–) terminal of the booster battery.

4. Make the final jumper cable connection to the

engine block or the furthest ground point away from

the discharged battery.

5. Start engine (refer to Operation Section). If engine

will not start after several tries, unit or battery may

need service.

6. After engine starts, leave cables connected for one

to two minutes.

7. Disconnect cables in reverse order.

8. Operate unit as normal to charge battery.

LUBRICATE UNIT

Apply oil at all pivot points and pin connections.

1. Negative terminal

2. Positive terminal

3. Battery

OF1671

Figure 8

WARNING: Make sure cables are clear of any

moving engine parts before starting engine.

REF LUBRICATION QTY

LOCATION

INTERVAL

1

REPACK

2

CASTER PIVOT

400 Hrs

OIL

ALL PIVOT

POINTS, PIN

CONNECTIONS

50 Hrs

OF1793

1

Figure 9