Variable speed control, Using the parallel guide – Global Machinery Company MAG2050R User Manual

Page 9

9

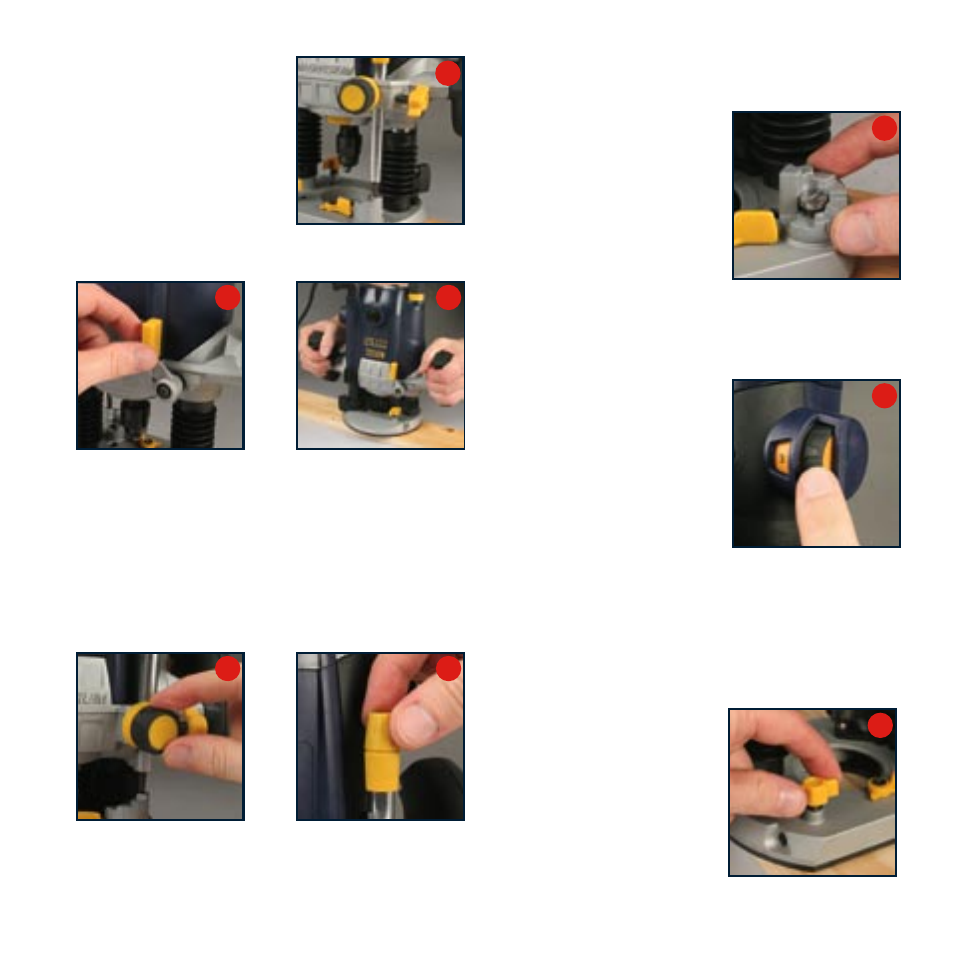

2. Allow the depth gauge (4) to

make contact with the turret stop

(8).

3. Loosen the depth lock lever (7)

and lower the machine body until

the router bit just touches the flat

surface. Tighten the depth lock

lever to maintain the position

of the bit just touching the flat

surface.

4. Take note of the measurement on the depth label.

5. Raise the depth gauge (4) and tighten using the depth gauge

locking knob (5). The difference in distance between the new

measurement and the original measurement will be equivalent

to the depth of cut. Use the depth adjustment (6) to set the

cutting depth. The micrometer depth adjustment (20) can be

used for precision setting. One complete turn of the micrometer

depth adjustment represents 1mm.

6. Loosen the depth lock lever (7) and raise the machine body.

7. When making a subsequent cutting operation, the final depth of

cut will be reached when the depth gauge (4) touches the turret

stop (8).

8. The depth turret stop (8) has

eight steps. By rotating the depth

turret stop it is possible to quickly

and easily set the depth at eight

different levels. This procedure is

particularly useful when you wish

to make a deep cut in a number

of stages.

Variable speed control

The variable speed dial (3) is located on the right hand side near

the power cord.

1. Adjust the variable speed dial

(3) to suit different working

materials. The tool cuts quicker

and smoother at different speeds

when working in different woods

or in plastic or aluminium.

2. Turn the dial to a higher number

for faster speed, turn the dial to

a lower number to reduce the

speed.

3. Determine the optimum speed by making a trial cut in a scrap

piece of material.

NOTE.

Using the correct speed for the job increases the life of

the bit.

Using the parallel guide

The parallel guide (17) is an

effective aid to cutting in a straight

line when chamfering or grooving.

1. Loosen the parallel guide locking

knobs (15).

2

3

3

5

5

8

1

1