Troubleshooting, Problem possible cause solution – Grindmaster 5511 User Manual

Page 22

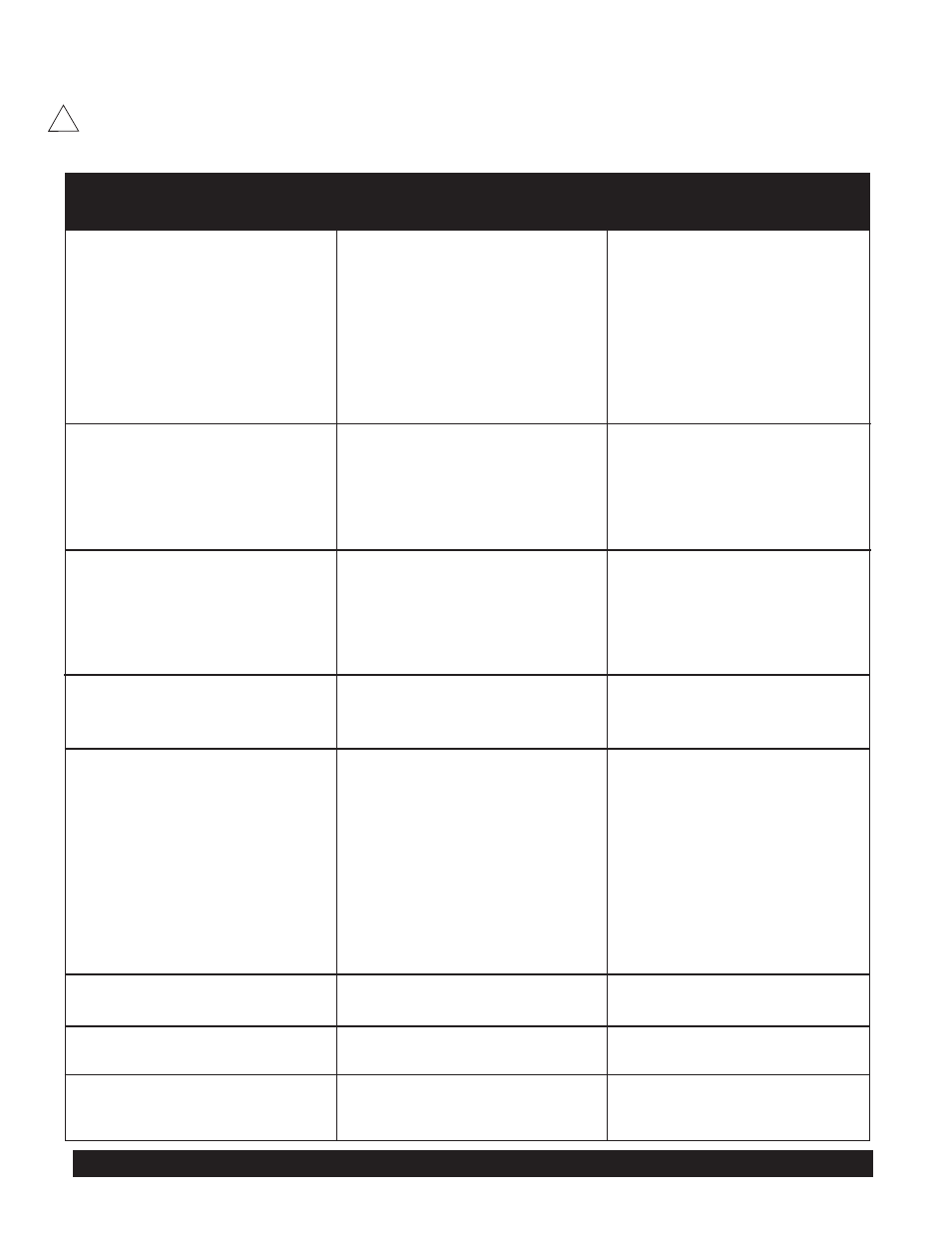

TROUBLESHOOTING

Only a qualified service technician should perform Electrical and mechanical adjustments or

repairs. Always disconnect power before attempting any maintenance procedures.

Problem

Possible Cause

Solution

Freezer will not run or freeze down

• Freezer not plugged in

• Circuit breaker tripped or fuse

blown

• Freezer in "CLEAN" position

• Dasher or scraper blades not

installed

• Obstructed condenser air flow

• Freezer in "Stand-by" mode

• (Model 5511) High pressure safety

switch tripped.

• Plug in machine

• Reset breaker or replace fuse

• Switch to "FREEZE"

• Install dasher and blades

• Allow 6” (15cm) on sides

• Switch to "FREEZE"

• Clean condenser, check for 6" air

clear on each side of unit

Product too soft

• Improper consistency control

setting

• Mixed soft, no overrun

• Carburetor set incorrectly

• Extended non-draw period

• Re-adjust consistency control

• Drain and refill with fresh mix

• Re-adjust carburetor

• Use STANDBY during slow

business periods

Improper product taste

• Mix spoiled

• Used rerun/leftover mix

• Frozen product too fluffy and

icy (Product frozen too long,

low draw)

• Check date code, use only

fresh mix

• Use only fresh mix

• Draw out 1 quart (1 liter),

dispose of product. Allow

product to refreeze

Frozen product too stiff, or freezer

runs continuously

• Consistency control set too firm

• Dispensing valve not fully

closed

• Re-adjust consistency control

• Close valve, lubricate properly

Frozen product not dispensing

• Power switch OFF

• Insufficient mix in storage

hopper, light on, beeper

• Carburetor in off position,

between holes

• Carburetor inlet hole clogged

• Foam buildup, liquid mix cannot

feed properly

• Drive belt broken or off of pulley

• Machine in STAND-BY mode

• Turn Power Switch to ON

• Refill storage hopper

• Set carburetor to proper hole

size

• Unclog carburetor

• Remove foam from hopper

using sanitized utensil

• Replace or repair

• Set switch to FREEZE

Liquid coming out of drain tube,

front of freezer

• Worn, defective or improperly

installed seal

• Replace and lubricate per

manual

Excessive dispensing valve leakage • Worn or defective O-Rings

• Replace and lubricate at each

cleaning

Scraping sound during freeze

down

• Frozen product scraping off of

cylinder walls

• Normal sound during freeze

down, goes away when product

is frozen to proper consistency

!

Crathco

®

5311 & 5511 Manual

Page 21