Tension/tracking – Grizzly G1011Z User Manual

Page 12

G1011 7" x 12'' Bandsaw

-11-

Tension/Tracking

If the tension seems correct, make the other

adjustments to the saw (aligning guides, tracking

and speed) and test run it on a scrap piece of

material. If the blade is not cutting properly, the

tension may be incorrect and you’ll need to read-

just the tension. Remember to reduce the blade

tension when the saw will not be in use, this will

help to prevent premature wear or breakage of

the blade.

TRACKING

To adjust tracking, disconnect the bandsaw from

the power source. Raise the saw bow as high

as possible and remove the cap screw from the

hinged wheel cover. This will allow you to see the

bandsaw wheel which has a machined step and

a groove on it.

The socket head cap screw and lock nut on the

top of the saw bow changes the plane of rotation

of this wheel. Turn the wheel by hand (remove

the belt guard and turn the motor pulley) for a

few revolutions and observe whether the edge of

the blade stays snug against the machined step.

If it does not, adjust the cap screw until the blade

stays against that step through several complete

revolutions of the blade.

Once it stays centered when rotated by hand,

lock the cap screw in place with the locking nut.

Reconnect the machine to power and turn the

machine on for just a few seconds. Observe the

action of the blade and the wheel during this test,

being sure to maintain a safe distance should

the blade become disengaged. If the blade stays

snug to the step, close the cover and secure with

the cap screw.

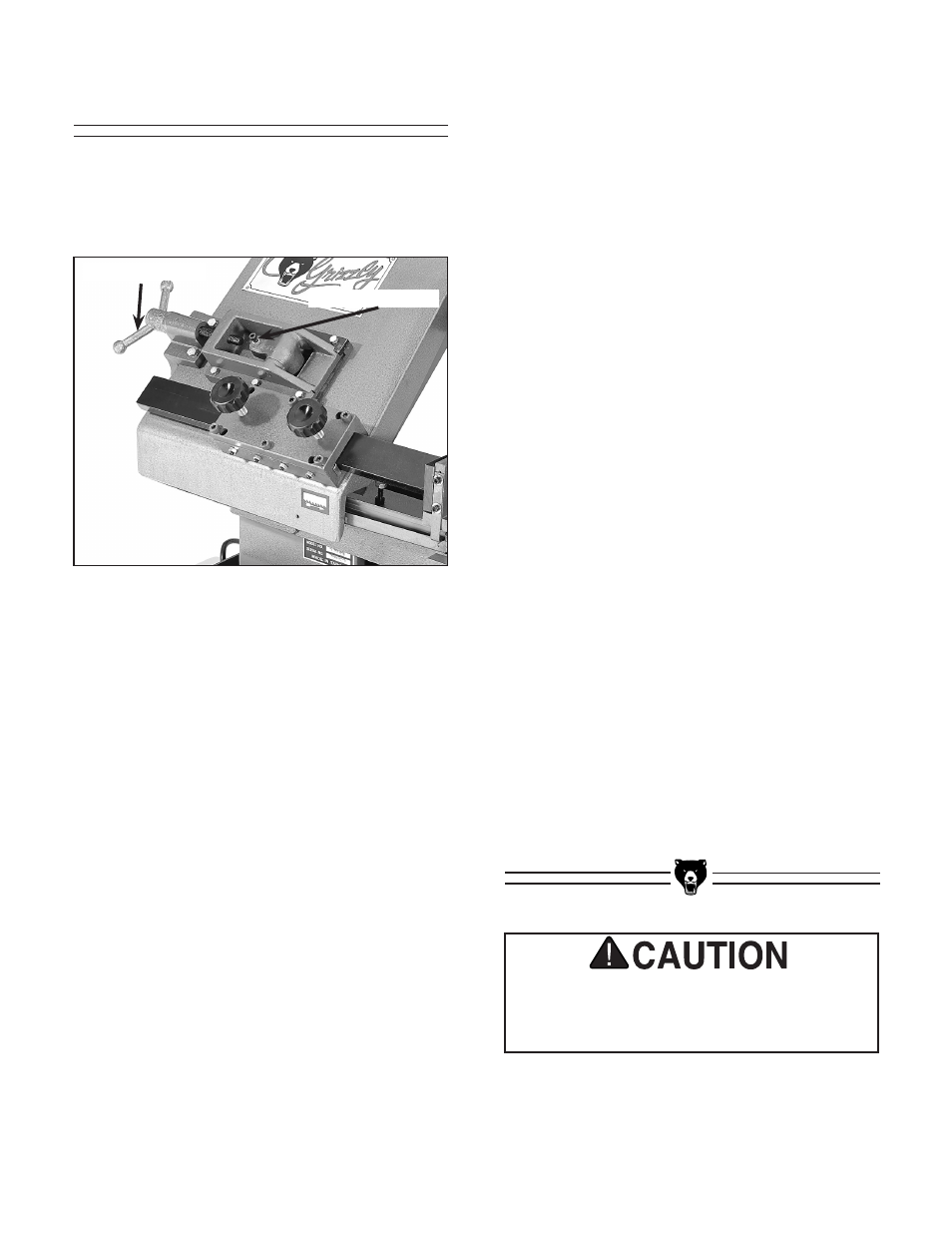

Proper blade tension and tracking are important

for optimum bandsaw performance.

See Figure

4 for bandsaw tension and tracking control loca-

tions.

Figure 4. Tension and tracking controls.

TENSION

Since a number of blade metal types and tooth

configurations will work in this saw, proper blade

tension is dependent upon the type of blade and

the material to be cut. Too much tension will

result in blade breakage. A properly tensioned

blade will track the cutting line accurately and the

cut will be smoother.

Initially proper blade tension can best be achieved

by determining the amount of blade deflection:

1. Ensure that the power is off and the saw is

unplugged. Slide the blade guide assembly

all the way to the left so the blade is fully

exposed.

2. Press, with moderate pressure, on the face

of the blade with your thumb.

3. Turn the tensioning knob at the top of the

machine to change the amount of tension.

The blade should flex no more than

1

/

4

".

The saw blade is dangerously sharp. Use

extra care when handling the blade, or work-

ing near it. Serious injury is possible.

Tension Control

Tracking Control